RE-based gear failure part feature reconstruction method

A technology of gears and parts, which is applied in the field of gear remanufacturing and reverse engineering, can solve problems such as low reconstruction efficiency and difficult precision, and achieve the effect of solving low precision and improving repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but it should be understood that the examples are used to explain the present invention, not to limit the present invention.

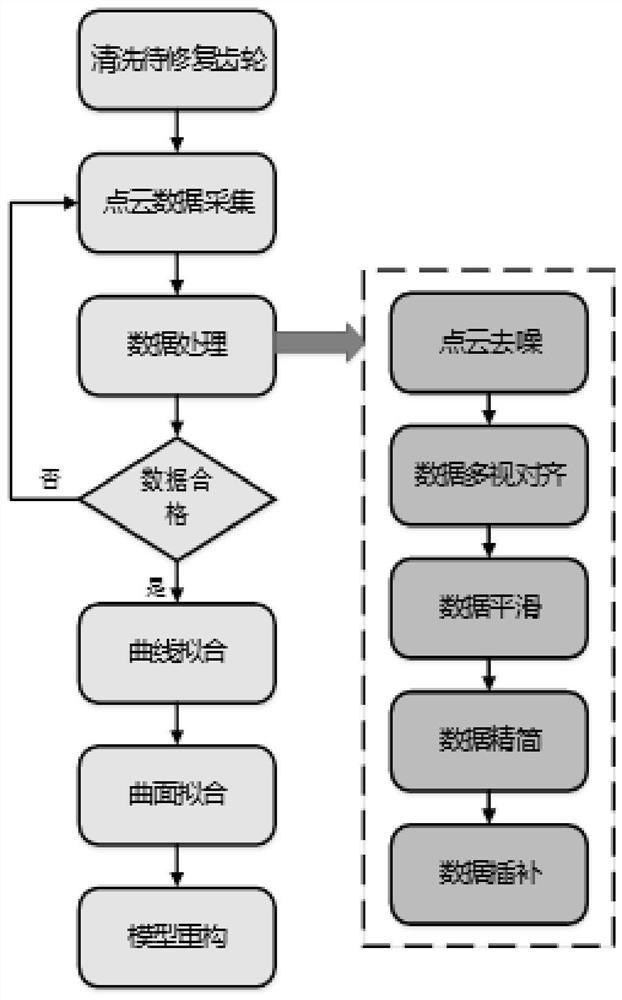

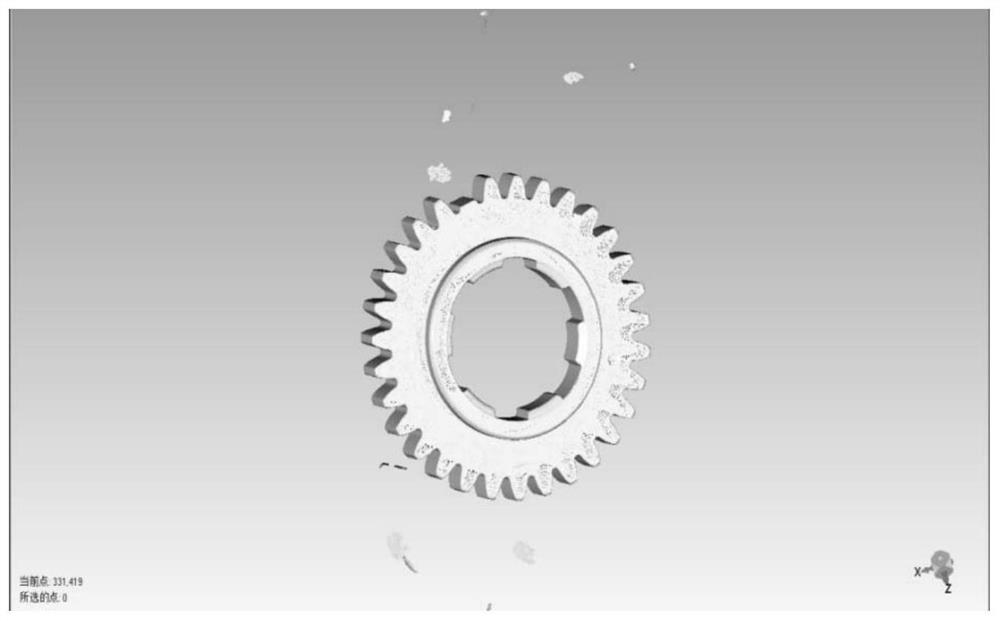

[0034] The feature reconstruction of gear failure parts is the basis of remanufacturing and repairing of failed gears. In order to solve the problem of low accuracy in the feature reconstruction of gear failure parts, a RE-based feature reconstruction method for gear failure parts is proposed. In practice, a machine tool The characteristics of the gear failure part are reconstructed as the background, and the model reconstruction accuracy of the method is verified. figure 1 Reconstruct the flow chart for the defect site model of the present invention. like figure 1 As shown, the gear to be repaired is cleaned first; then the point cloud data acquisition and data processing are carried out; the data processing includes point c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap