Microelectronic efficient heat dissipation device

A heat dissipation device and microelectronics technology, applied in cooling/ventilation/heating transformation, modification through conduction heat transfer, modification using liquid cooling, etc., can solve the problem of large space for heat dissipation devices, accelerated chip loss, and thermal function decline, etc. problems, to prevent dust from contacting with silica gel, prolong service life and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

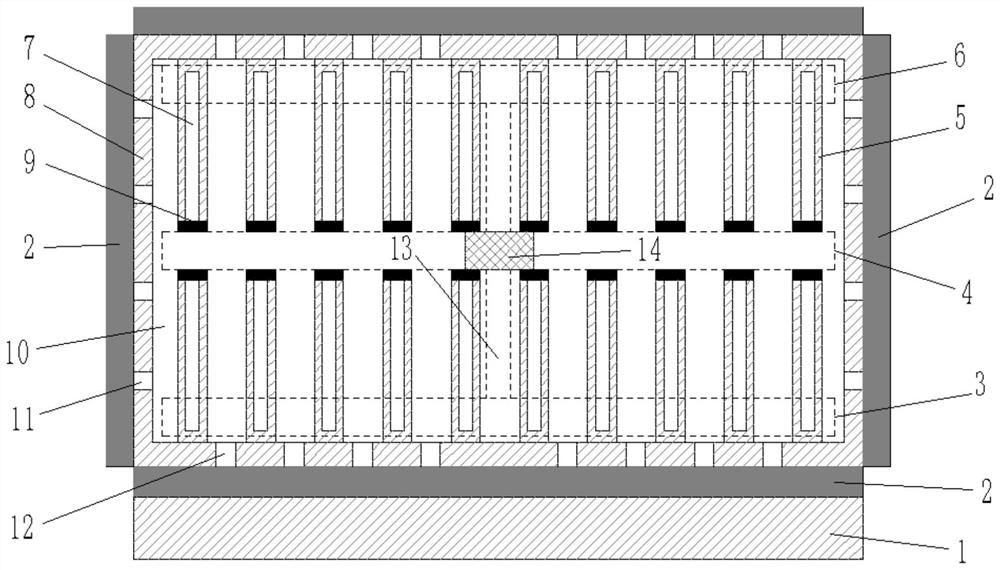

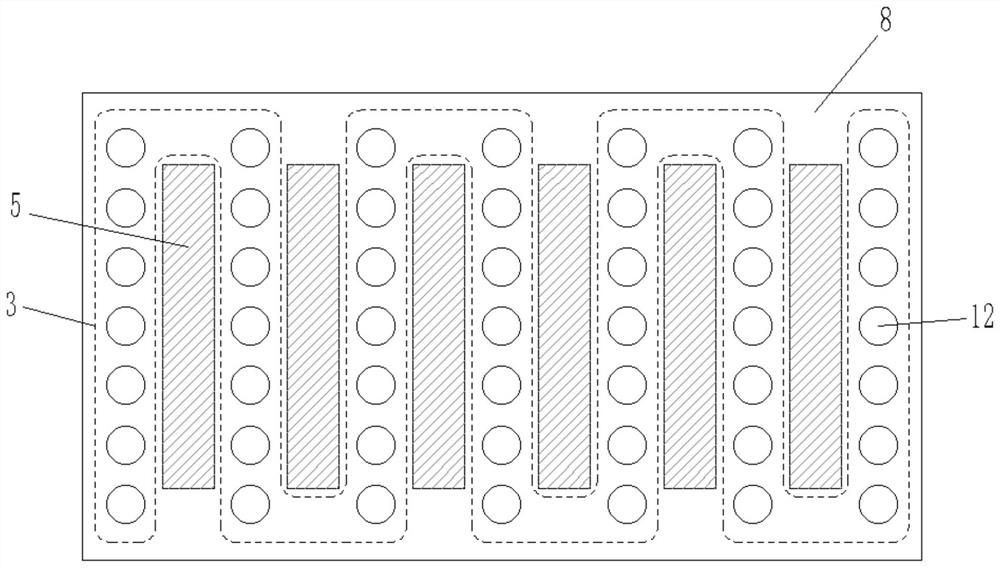

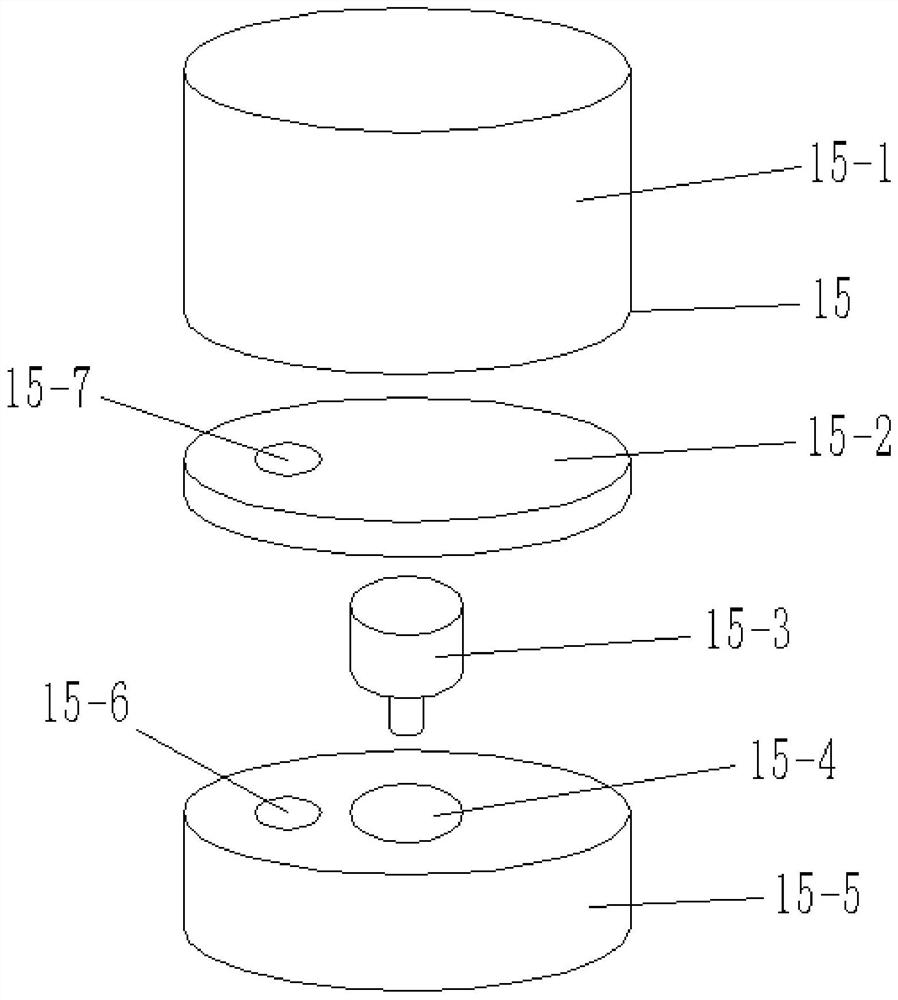

[0022] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0023] In this application document, unspecified component models and structures are all prior art known to those skilled in the art, and those skilled in the art can set them according to the needs of the actual situation. In the embodiments of this application document No specific restrictions are made.

[0024] Specifically, such as Figure 1-3 As shown, the embodiment of the present invention provides a high-efficiency heat dissipation device for microelectronics, including a heat dissipation plate 8, the heat dissipation plate 8 is adhered to the heating surface of the chip 1 through silica gel 2, the heat dissipation plate 8 is a hollow structure, and the heat dissipation plate The inner cavity 10 of 8 is provided with

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap