Steering knuckle main pin hole inner end face run-out detection device

A technology of runout detection and internal end face, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of high installation accuracy, inconvenient use, and complicated installation process, and achieve good versatility and structure. Simple and reliable, high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

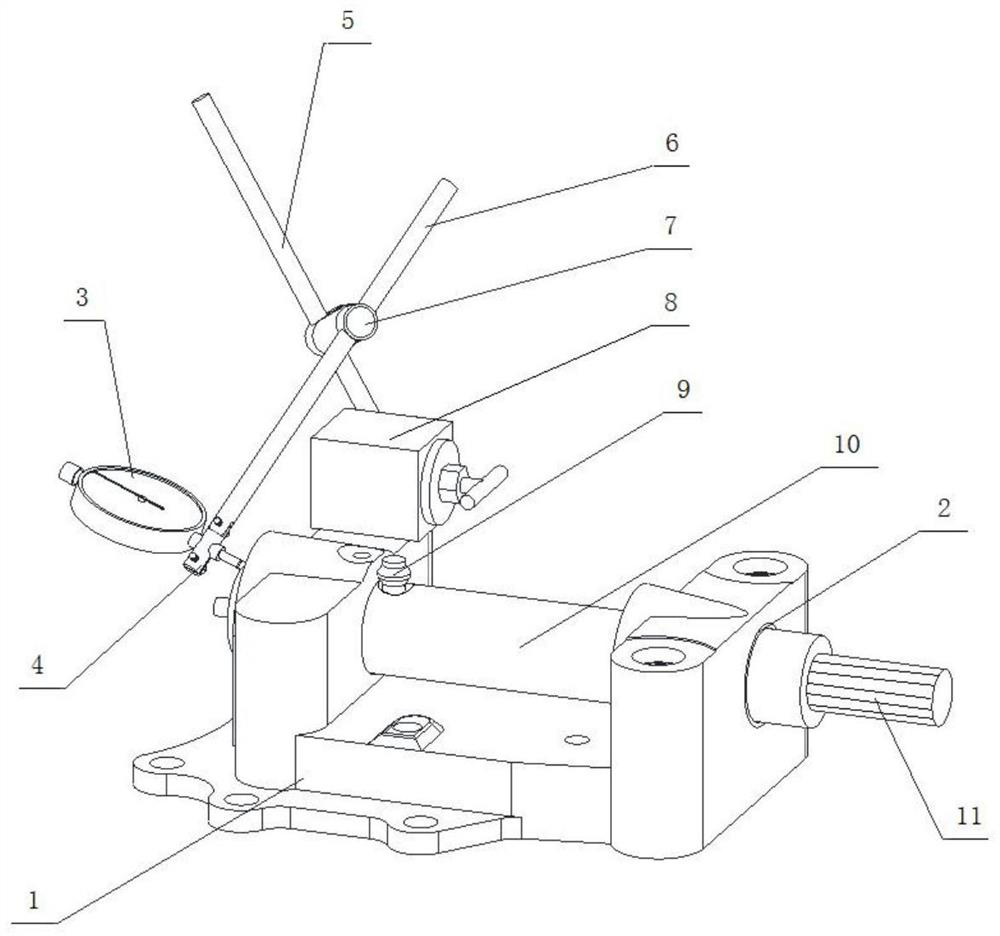

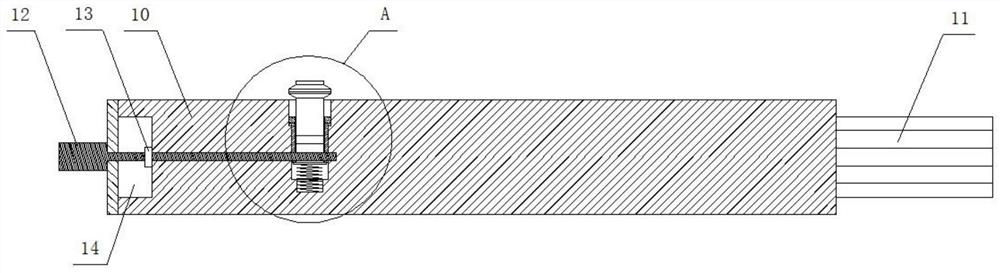

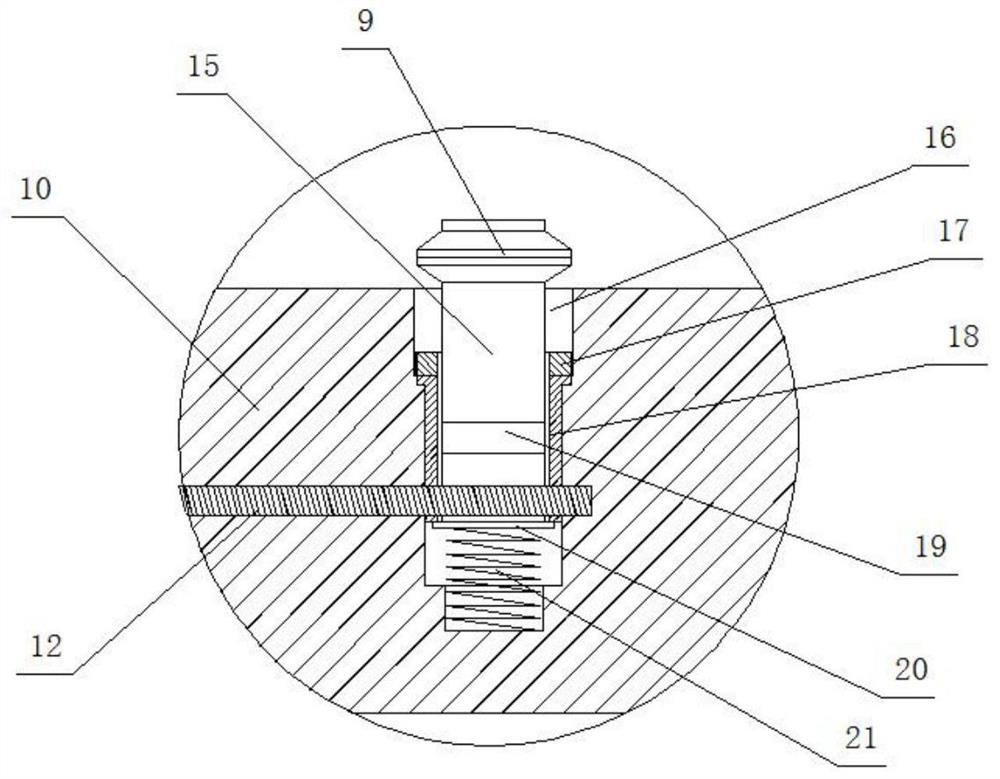

[0041] Such as Figure 1 to Figure 3 As shown, a device for detecting runout of the inner end surface of the steering knuckle kingpin hole includes a dial indicator, a detection component and a bracket for making the dial indicator and the detection component contact. The detection component includes a shaft core 10, an induction screw 15 and a Due to the telescopic adjustment structure of the adjustment induction screw 15, the cylindrical surface of the shaft core 10 is in a transitional fit with the kingpin hole 2 of the steering knuckle 1, and the induction screw 15 is placed in the radial placement hole of the shaft core 10 through the adjustment structure, and the radial placement A thrust spring 21, a push plate 20, a retaining sleeve 18, a retaining sleeve fastener 17 and an induction screw 15 are sequentially placed in the hole from the inside to the outside. The lower end of the screw 15 passes through the retaining sleeve fastener 17 and the retaining sleeve 18 to conta

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap