Gauge capable of detecting concentricity of two ends of columnar valve cover

A technology of concentricity and bonnet, which is applied in the field of inspection tools that can detect the concentricity requirements at both ends of a cylindrical bonnet, can solve the problem of low detection frequency, increase the detection frequency, increase the qualified rate of warehousing, and reduce unqualified products outflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029]The present application will be further described in connection with the accompanying drawings, and it is necessary to indicate that the following detailed descriptions are intended to be further described herein, and cannot be understood as limiting the scope of the present application, those skilled in the art can The above-described application has made some non-essential improvements and adjustments to this application.

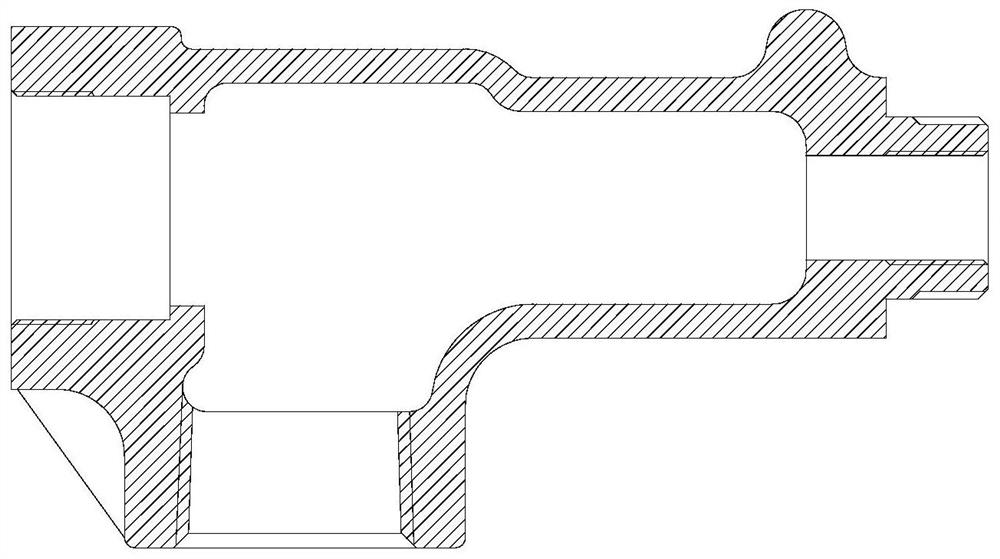

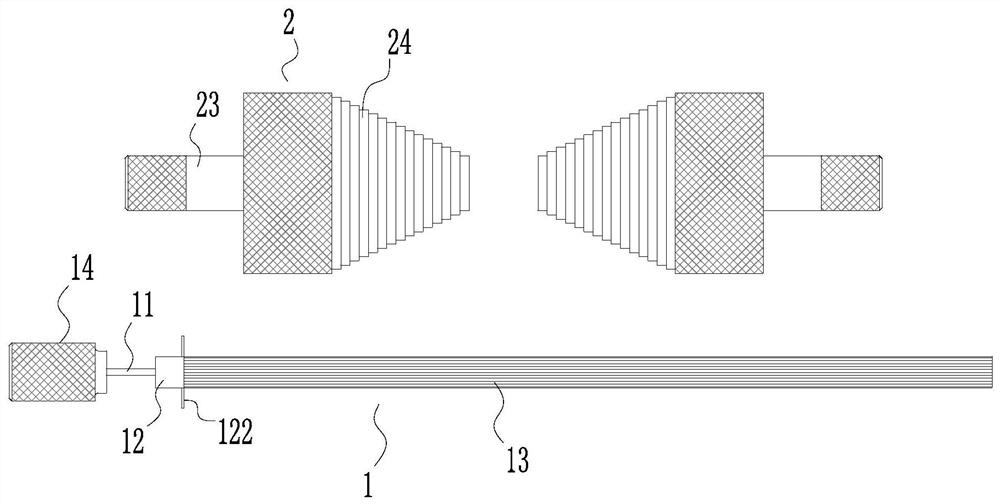

[0030]CombineFigures 2 to 8As shown, a trick that detects two ends of the columnar valve cover, including:

[0031]A heart 1;

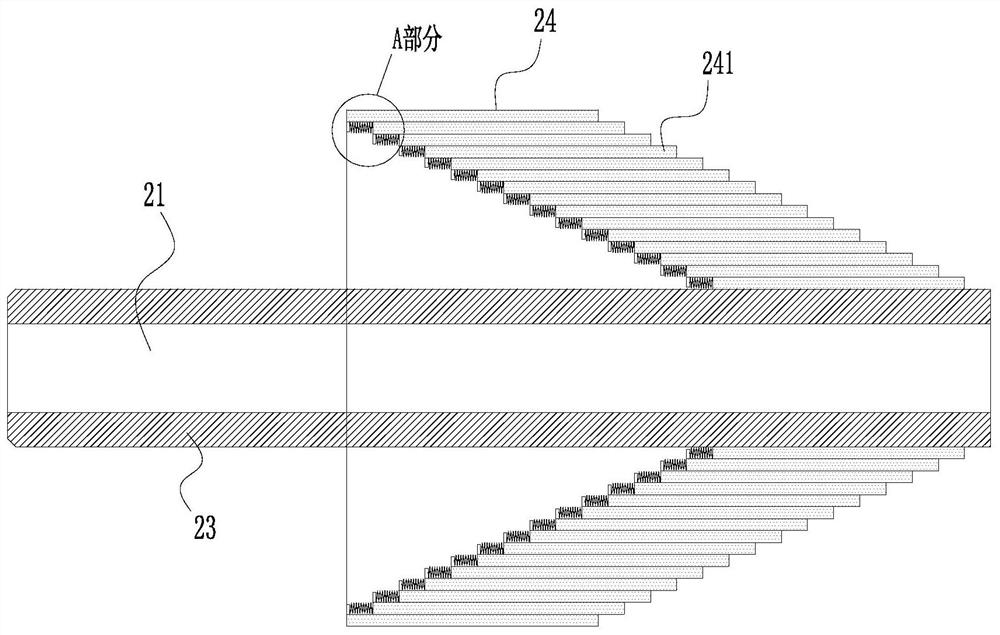

[0032]The two positioning cores 2, the positioning core 2 is opened with a through hole 21 equal to the outer diameter of the concentric rod 1, and a plurality of different outer diameters are formed outside the positioning core 2.

[0033]In the present invention, the threaded portion 22 outside the positioning core 2 is used to connect to the columnar valve end threaded hole, and the rear through hole 21 is concentric with the threaded hole,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap