Coal mine crushing device for coal mining

A crushing device, coal mine technology, applied in grain processing, etc., can solve problems that threaten the life, health and safety of workers, fail to solve, increase the cost of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

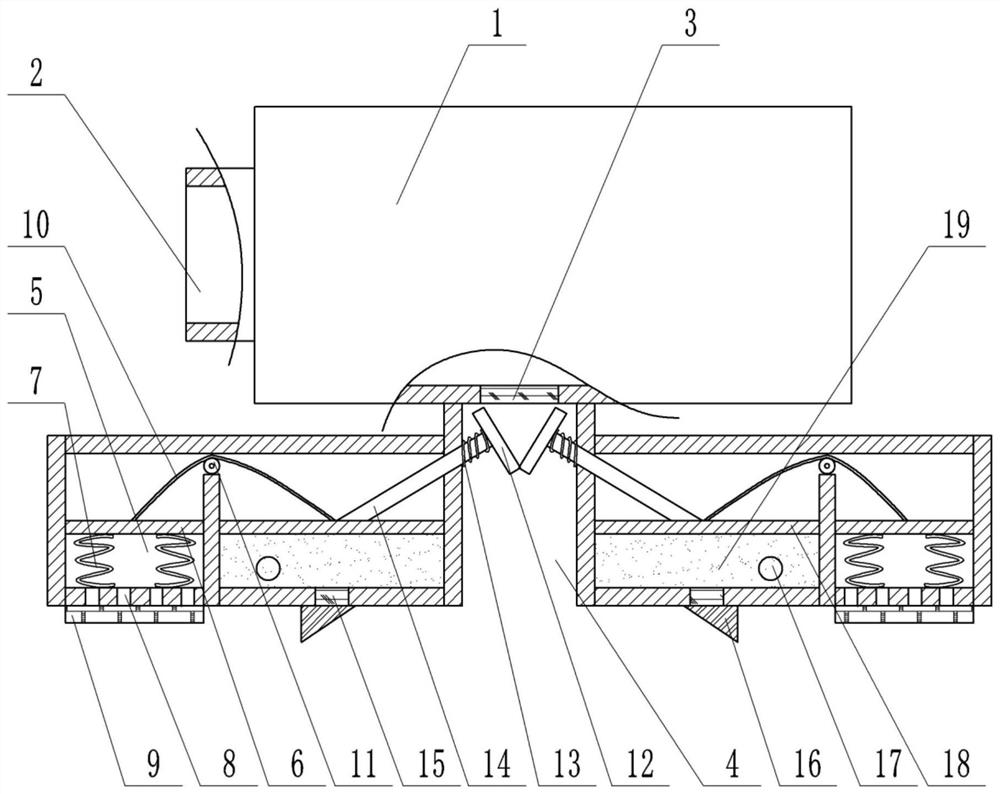

[0024] The reference signs in the drawings of the description include: crusher 1, feed port 2, discharge port 3, discharge channel 4, cylinder 5, second piston 6, pressure spring 7, one-way air intake valve 8, cloth bag 9 , rope 10, runner 11, swash plate 12, return spring 13, push rod 14, one-way liquid discharge valve 15, shower nozzle 16, one-way liquid inlet valve 17, first piston 18, solution cylinder 19.

[0025] The embodiment is basically as attached figure 1 Shown: a coal mine crushing device for coal mine development, including a crusher 1, a discharge channel 4 and a dust removal mechanism. The crusher 1 is provided with a material inlet 2 and a material outlet 3, and the material outlet 3 is provided with a screen. Crusher 1 is a closed crusher 1, so that in the process of crushing coal mines, a large amount of coal dust will not be generated during the crushing process, which effectiv

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap