Hardware machinery reciprocating uniform paint spraying equipment based on magnetic clamping

A technology of magnetic clamping and painting equipment, applied in the direction of spraying devices, etc., can solve the problems of excessive spraying, uneven painting, looseness, etc., and achieve the effect of avoiding falling off and uniform painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

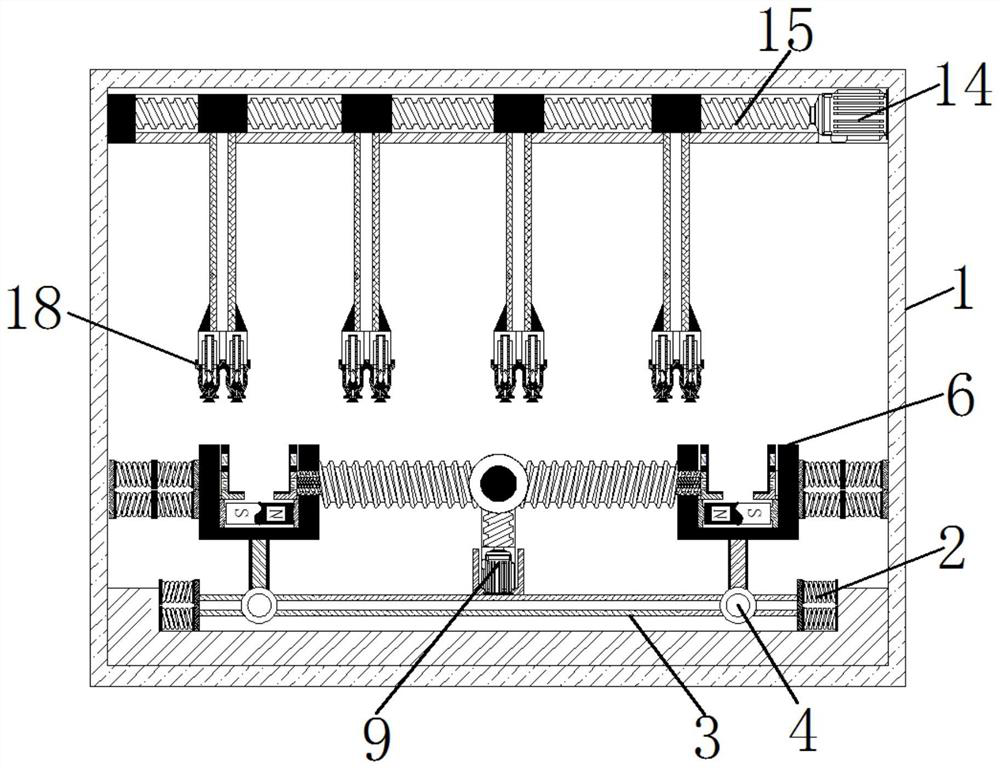

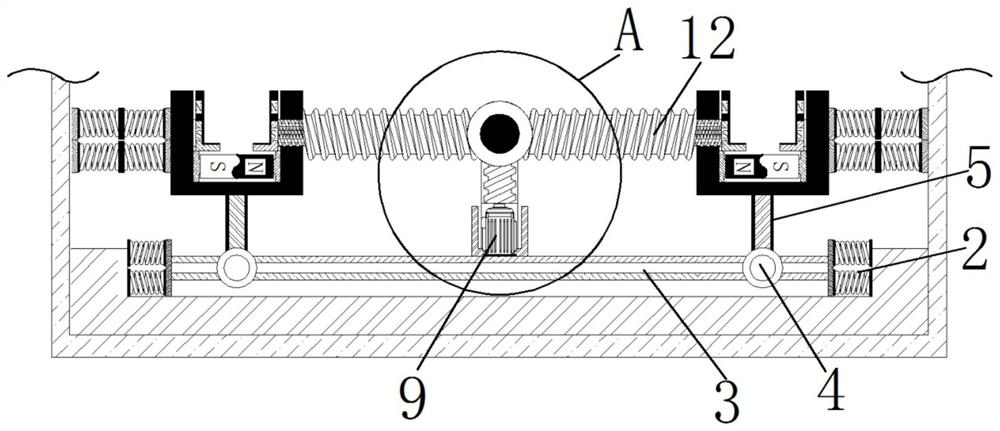

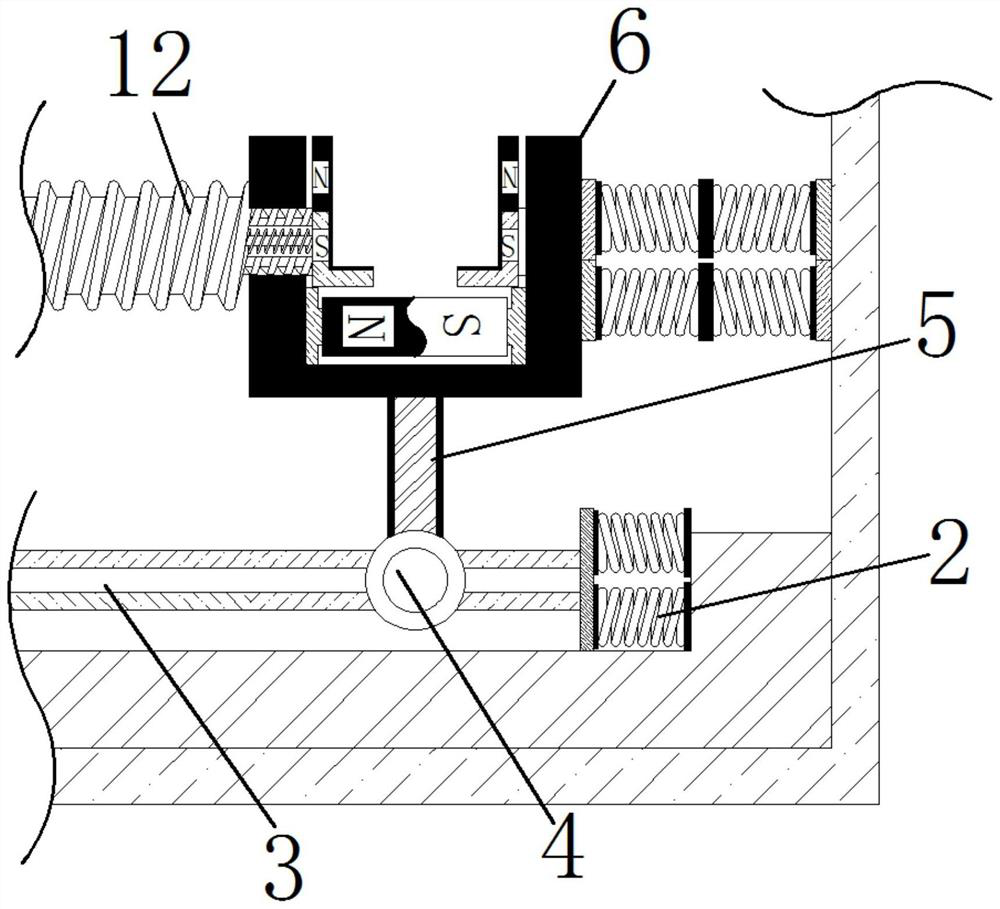

[0025]SeeFigure 1-6A magnetic-clam-based hard metal mechanical reciprocating average painting device, including the equipment main body 1, the inside of the apparatus main body 1 is fixedly mounted with a fixed spring 2, and the outer side of the fixed spring 2 is fixedly connected to the outer activity of the slider 3. Connecting a sliding block 4, the outer side of the sliding block 4 is fixedly coupled with the connecting rod 5, and the connecting rod 5 is fixed to one end of the sliding block 4 fixed to the clamping mechanism 6,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap