Stirrer capable of adjusting thickness of food materials and control system of stirrer

An adjustable, agitator technology that can be used in food science, meat cutting/trimming, slaughtering, etc., to solve problems such as equipment misopening, equipment damage, energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

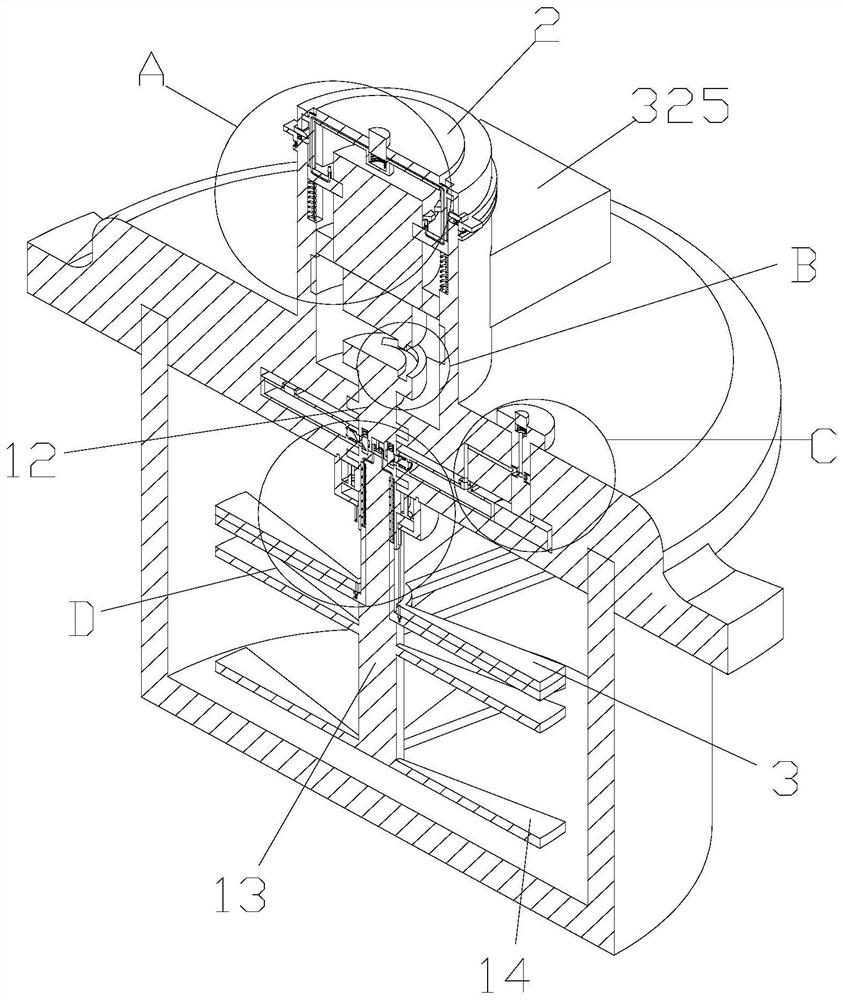

[0033] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

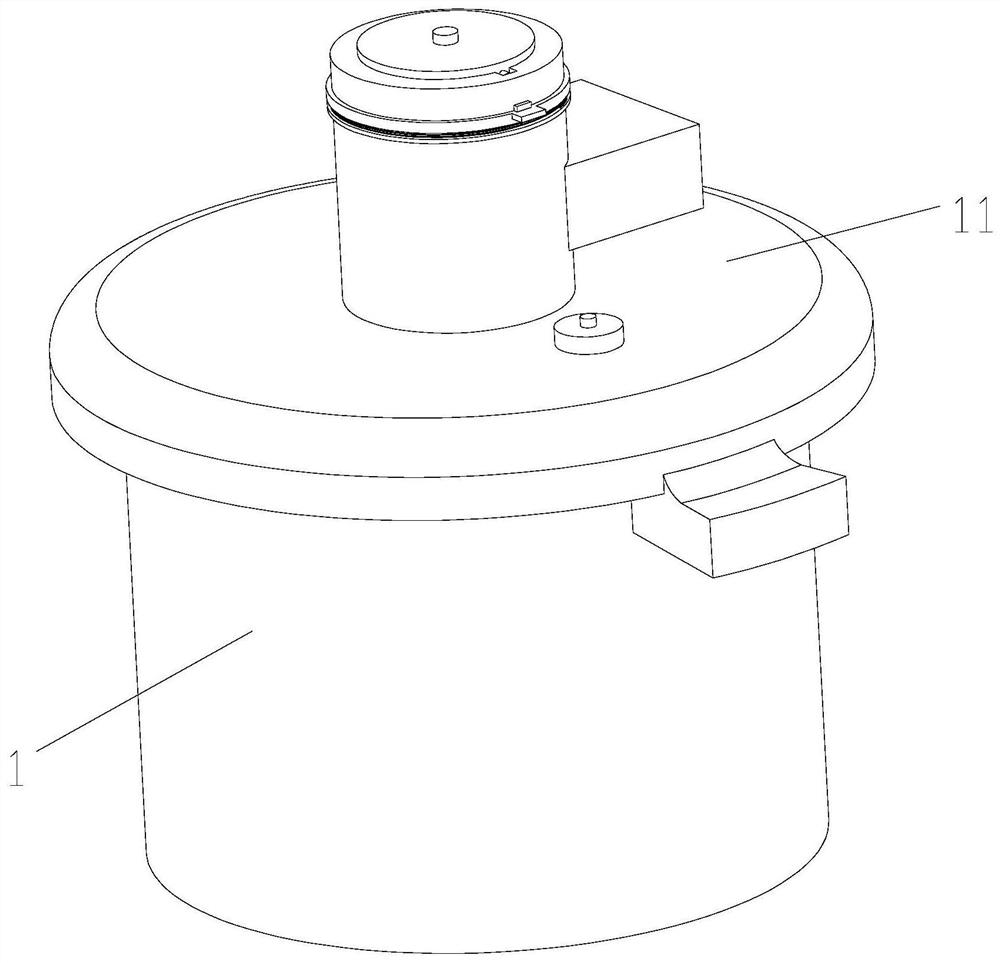

[0034] Such as Figure 1-12 As shown, a stirrer with adjustable thickness of ingredients includes a tank body 1, a cover body 11 arranged on the tank body, a first rotating shaft 12 arranged on the cover body, and a first rotating shaft arranged on the first rotating shaft. A second rotating shaft 13 at one end, a plurality of first cutting knives 14 arranged on the second rotating shaft, a driving device 2 arranged on the cover, an adjusting device 3 arranged on the cover; The tank body and the cover body are connected by buckles, the first rotation shaft can rotate relative to the cover body, and the second rotation shaft can rotate relative to the cover body; the cover body c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap