Mechanical lock

A technology for mechanical locks and front locks, which is applied to non-mechanical transmission-operated locks, building locks, and devices that prevent keys from being removed from the lock, which can solve problems such as hidden safety hazards and inability to unlock the lock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

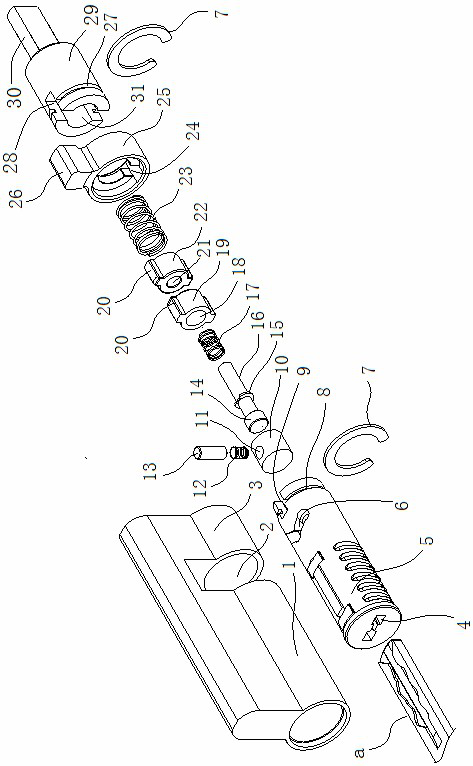

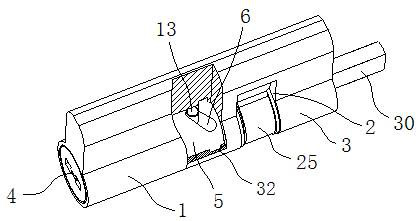

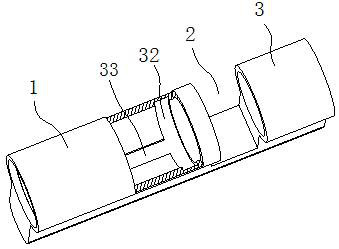

[0020] See figure 1 — Figure 4 , Image 6 , the mechanical lock head provided by the present invention includes a front lock tube 1 and a rear lock tube 3, an emergency lock cylinder 5 and a lock rod 30 arranged in the front lock tube 1 and the rear lock tube 3, and an emergency lock cylinder 5 and a lock rod 30 arranged in the front lock tube 1 and the rear lock tube The dial 25 connected to the emergency lock core 5 and the lock bar 30 through the clutch assembly between the lock tubes 3; the key slot 4 of the emergency lock core 5 is a blind hole, and the emergency lock core 5 and the clutch assembly A push block assembly is provided; the push block assembly includes a rotatable push block 10 arranged in the rear of the emergency lock cylinder 5 and a thrust column 13 arranged radially on the push block 10, and the push block 10 is provided with a spring hole 11 The thrust column 13 is movable in the spring hole 11, and the spring 12 is arranged between the thrust column 13

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap