Oil seal lubrication smearing equipment

An oil seal and equipment technology, which is applied in the field of oil seal lubrication and coating equipment, can solve the problems of easy running off of oil seals, inability to guarantee oil coating coverage, etc., and achieve the effect of saving lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

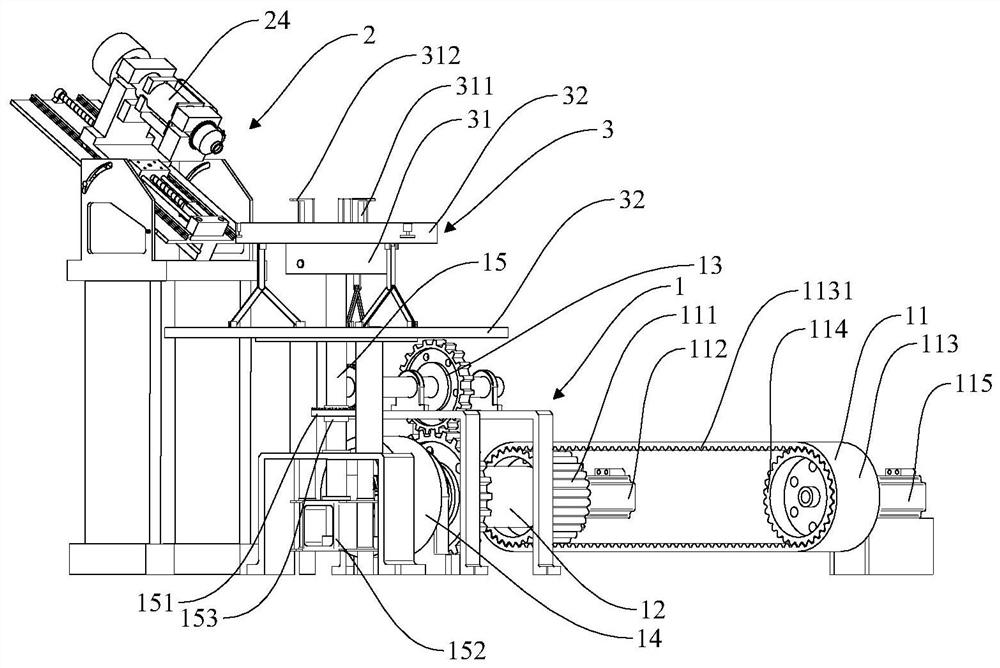

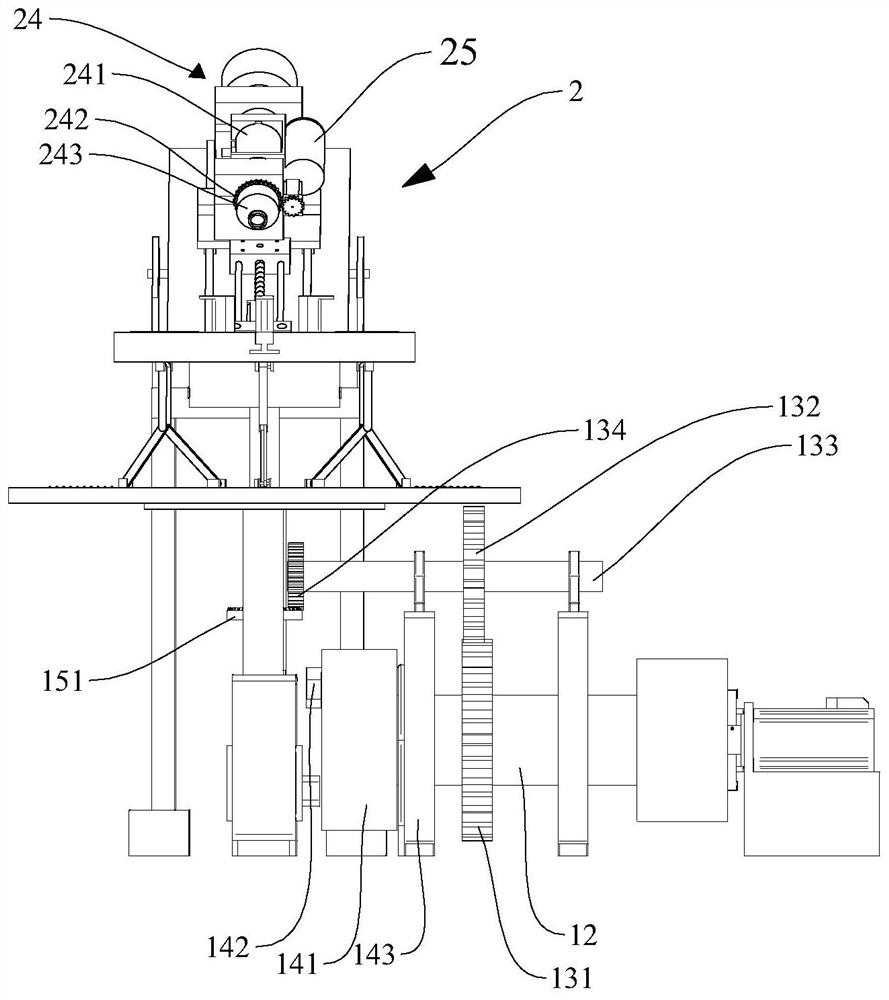

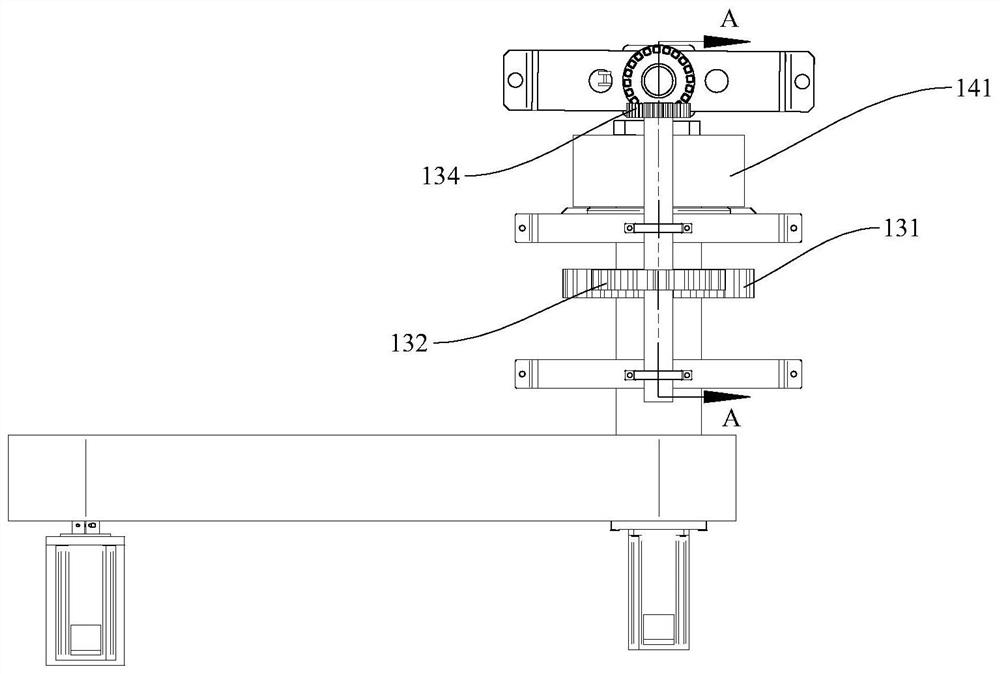

[0085] In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

[0086] It should be noted that the technical terms or scientific terms used in the embodiments of the present invention should be understood from the art of people with general skills in the art of the present disclosure, unless otherwise defined. The "first", "second" and similar words used in this disclosure do not represent any order, quantity, or importance, but is only used to distinguish between different components. Similar words to "include" or "include", meaning that the elements or objects of the previously mentioned previously enumerated elements or objects that appear later in the word, without excluding other elements or objects. Similar words such as "Connect" or "Connect" are not limited to physical or mechanical connections, but may include electrical connection

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap