Rigidity-adjustable particle damper for high-rise civil structure

A technology for structure and shock absorber, applied in the direction of earthquake resistance, building components, building types, etc., can solve the problems of narrow vibration reduction frequency band, single vibration control, sensitive to changes in the working environment, etc., and achieve the effect of preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

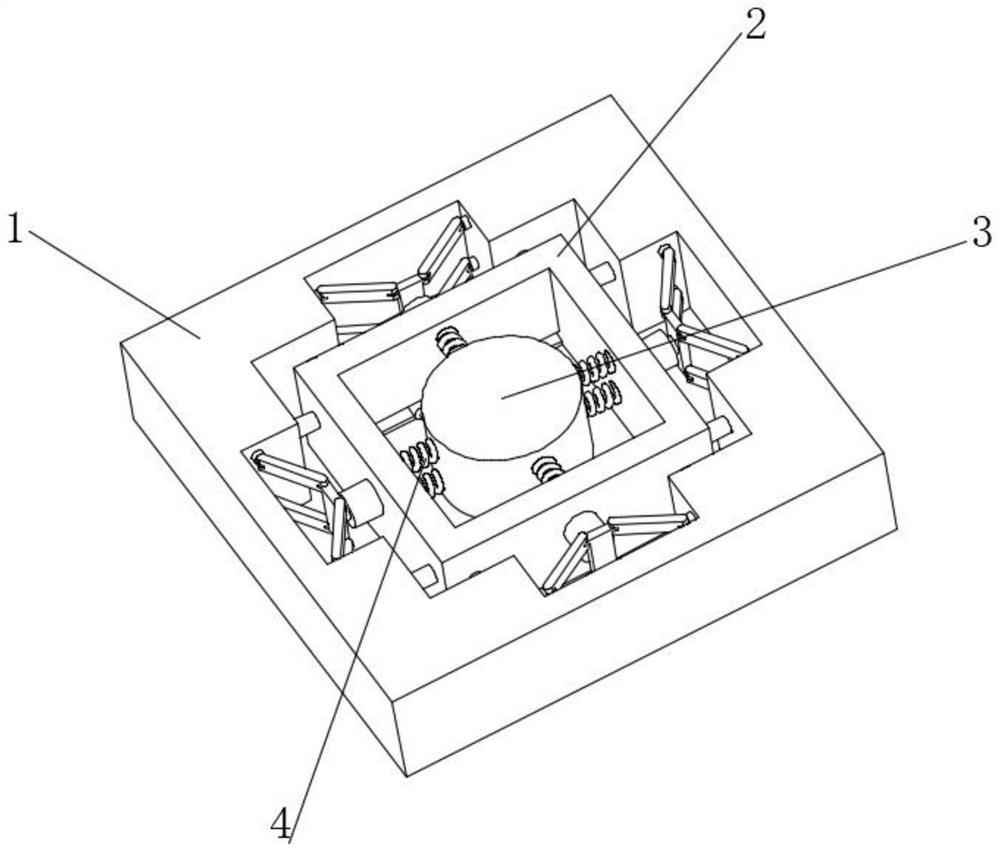

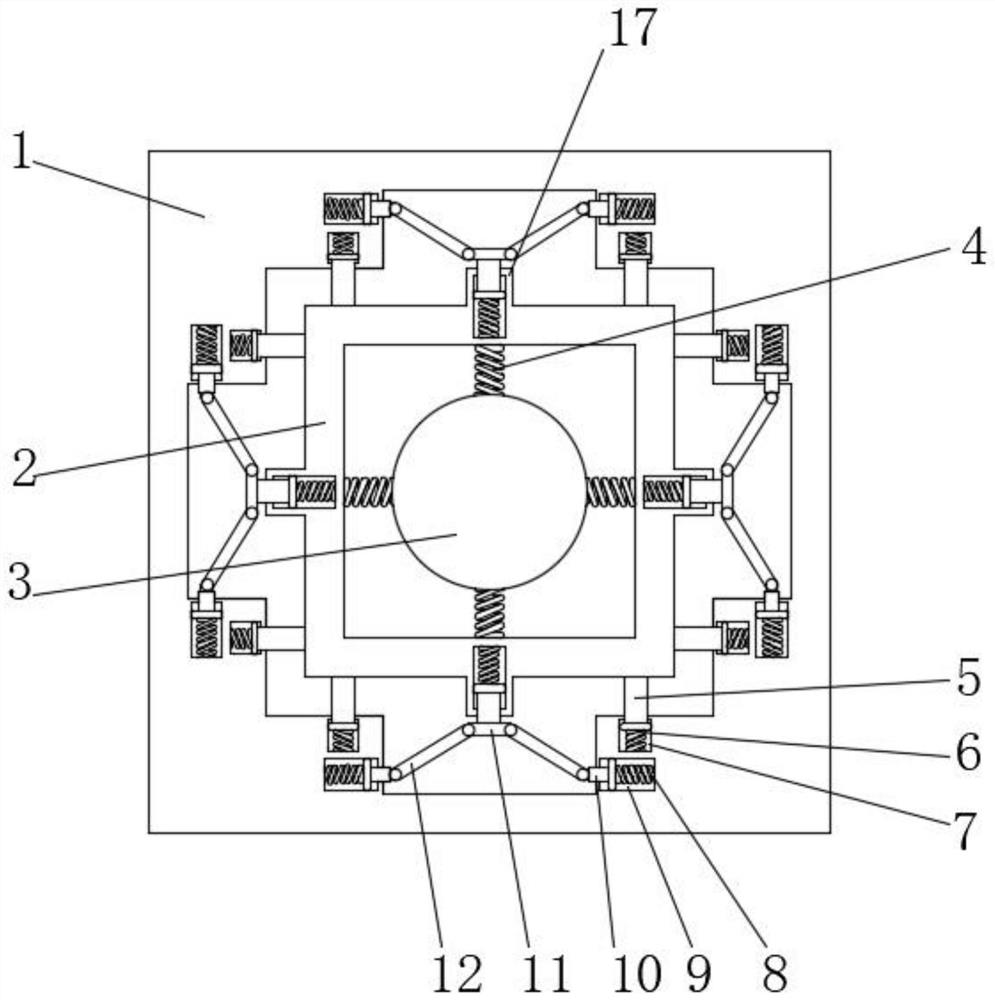

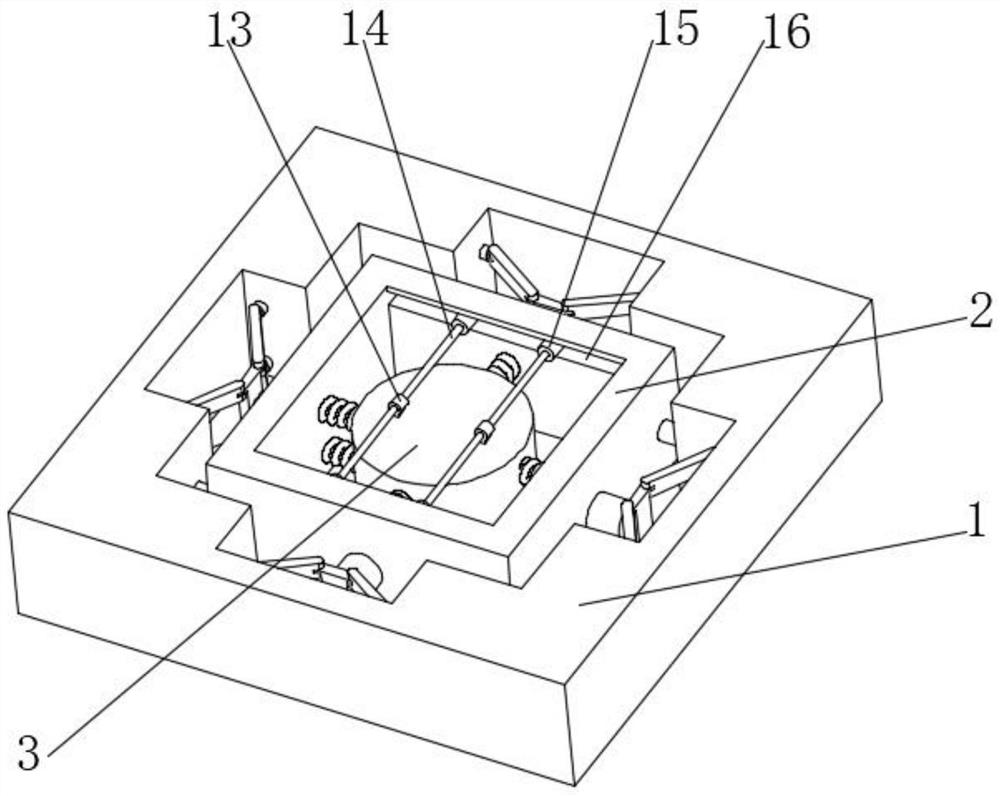

[0023] see Figure 1-6 , the present invention provides the following technical solutions: a particle shock absorber with adjustable stiffness for high-rise civil structures, including a main body 1, a frame body 2 is installed inside the main body 1, and a second groove 7 is provided at both ends of the main body 1, The inside of the second groove 7 is equipped with a second spring 6, and one end of the second spring 6 is equipped with a second guide rod 5, and the end of the second guide rod 5 away from the second spring 6 is equipped with a frame body 2, and the second groove 7 is provided with a first groove 9 below, and a first spring 8 is installed inside the first groove 9, and a first guide rod 10 is installed on one end of the first spring 8, and the first guide rod 10 is far away from the side of the first spring 8. One end is rotatably connected with a connecting rod 12, a box body 3 is installed inside the frame body 2, a spring device 4 is installed on the inner wall

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap