Concrete density detector for municipal engineering detection

A technology for engineering inspection and concrete, applied in the field of concrete density detector, can solve the problems of small test range, deviation in accuracy, inconvenient measurement, etc., and achieve the effects of convenient use, expansion of test range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

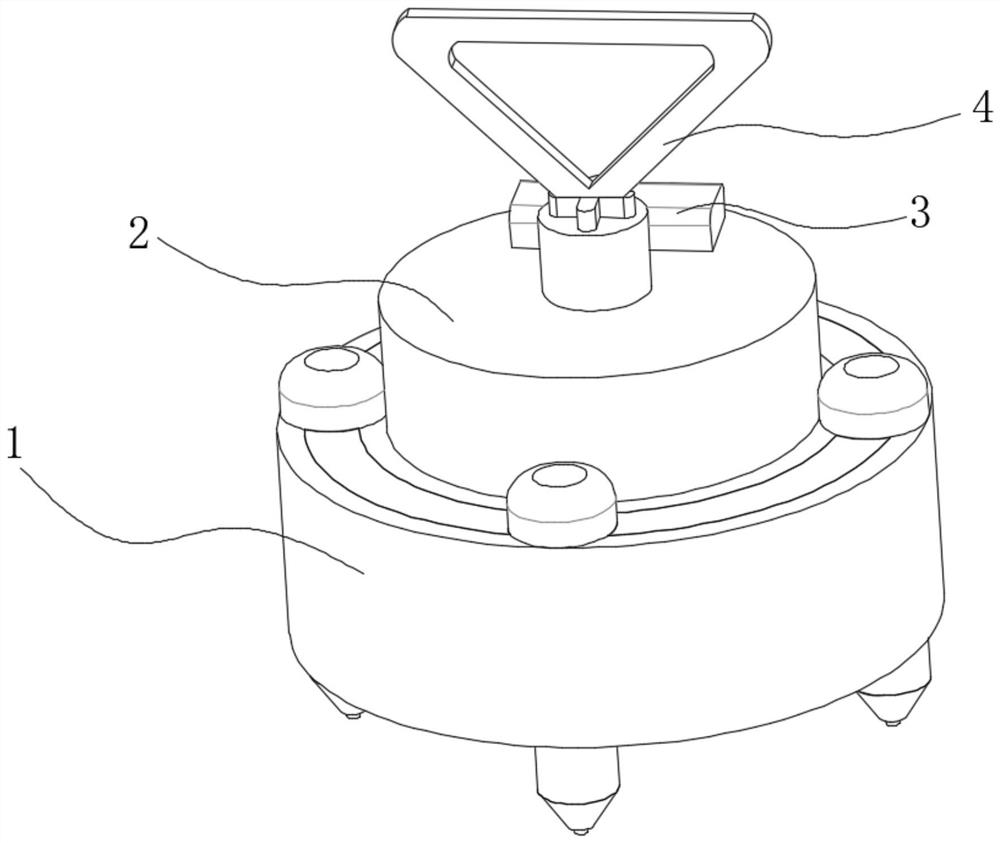

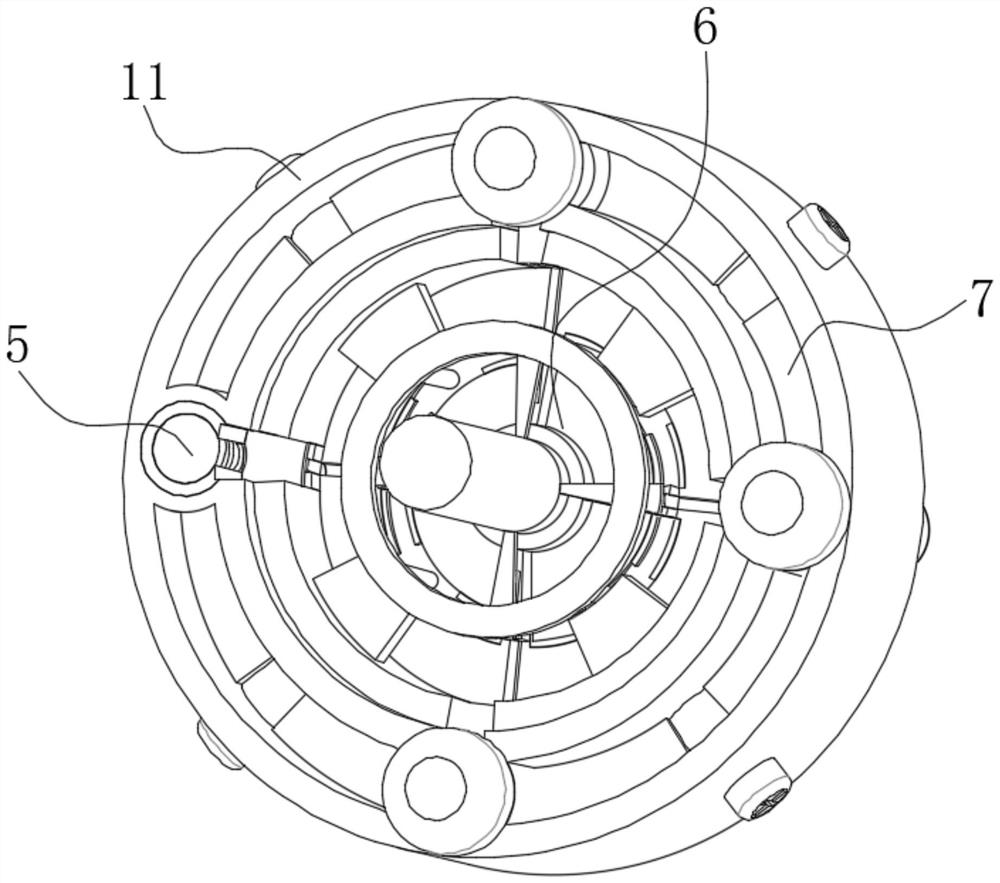

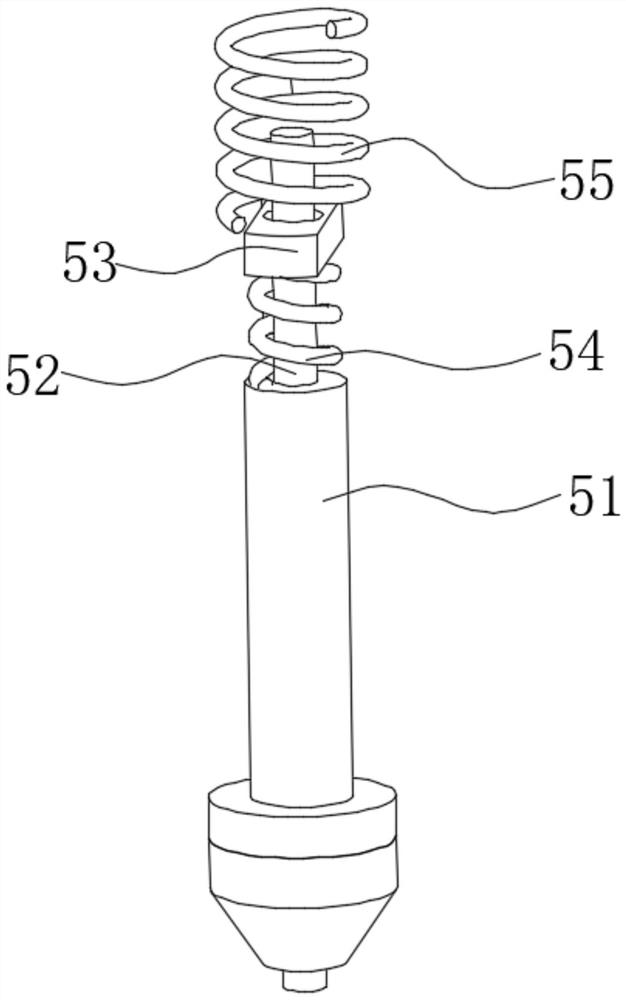

[0024] use Figure 1-Figure 6 A concrete density detector for municipal engineering detection according to an embodiment of the present invention is described as follows.

[0025] Such as Figure 1-Figure 6 As shown, a concrete density detector for municipal engineering detection according to the present invention includes a rebound hammer 1, and the inner cavity of the rebound hammer 1 is fixedly connected with an external column 2, and the outer surface of the external column 2 is The lower part is fixedly connected with the inner wall of the hammer 1, and the upper surface of the external column 2 is fixedly connected with a display meter 3, and the inner cavity of the display meter 3 is fixedly connected with the inner cavity of the rebound hammer 1 by electric wires. The axis of the column 2 is fixedly connected with a handle 4 through an opening, and the bottom end of the handle 4 is fixedly connected with the inner chamber of the rebound hammer 1 through the connecting co

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap