Optical detector with precise positioning function

An optical detector and precise positioning technology, applied in the field of optical detection, can solve the problems of affecting the detection accuracy, easy adhesion of dust on the surface of the lens, inconvenient clamping of the magnifying lens, etc., to improve accuracy, prevent offset, and facilitate use quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

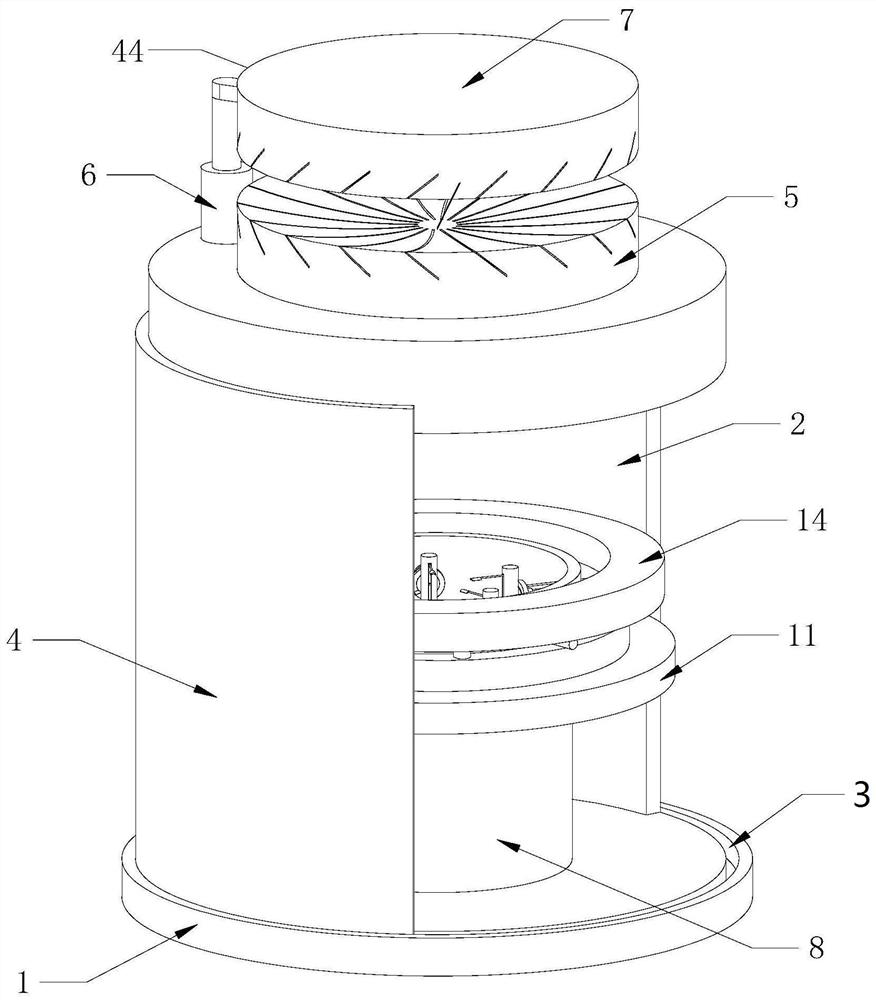

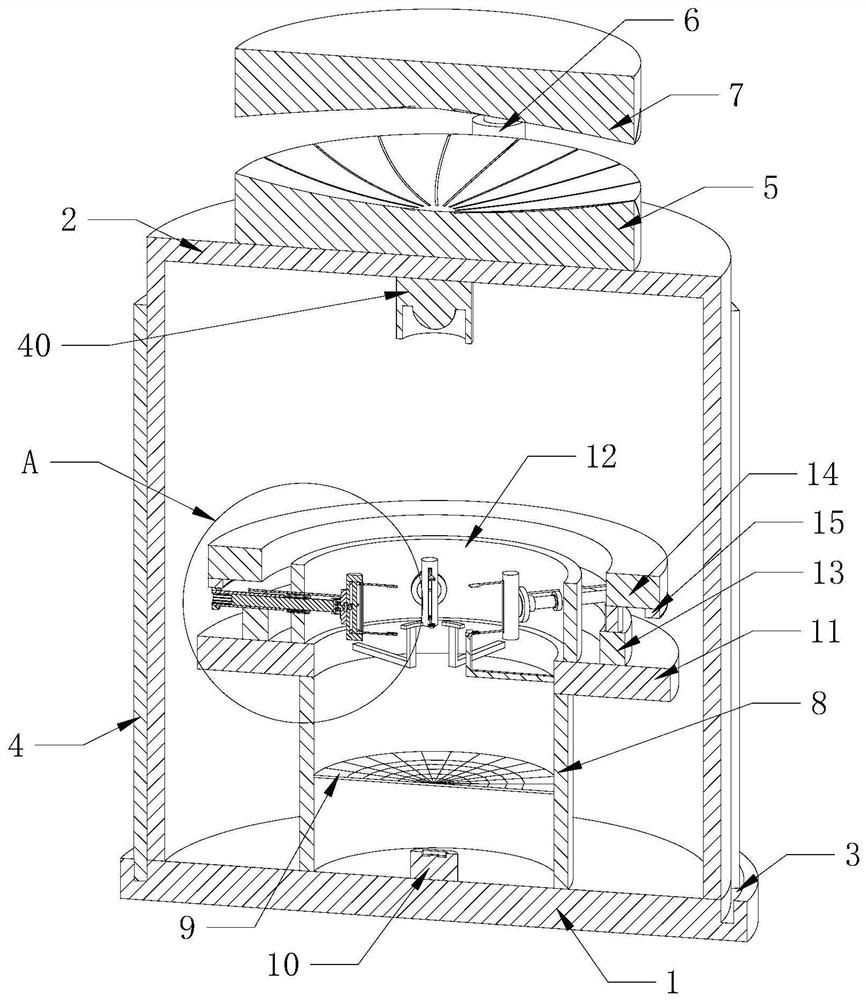

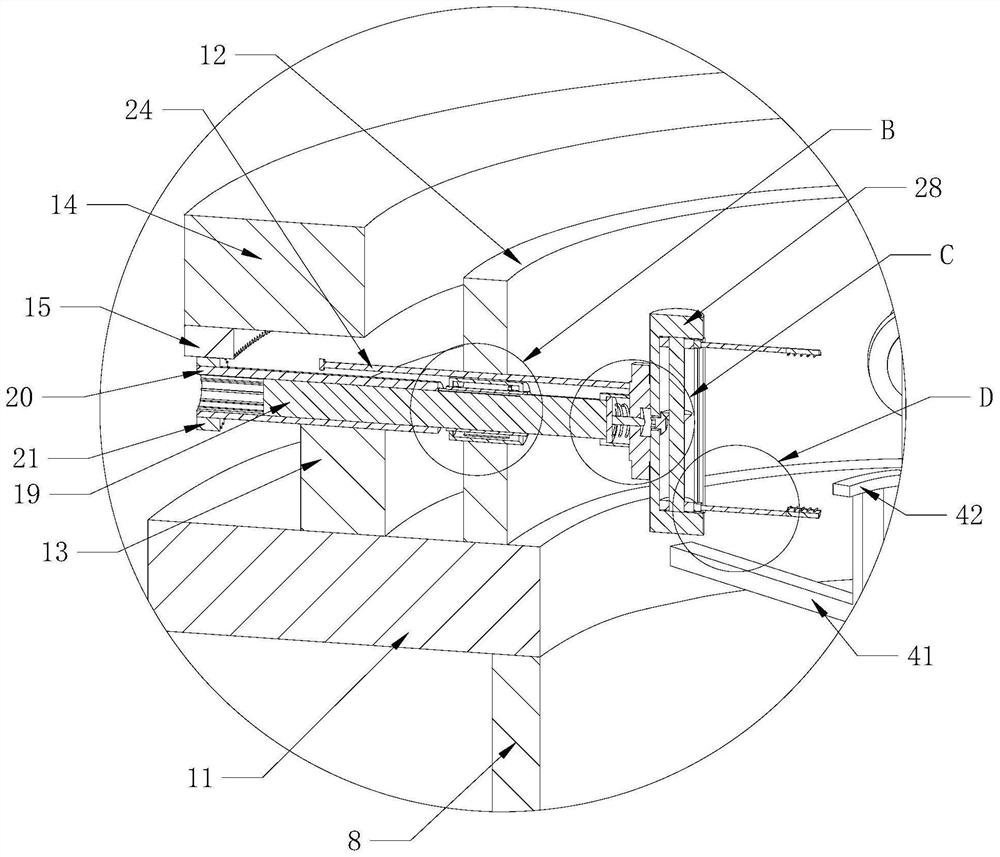

[0031] see Figure 1-6 , the present invention provides a technical solution: an optical detector with precise positioning function, including a base 1, a housing 2 is fixedly installed on the top of the base 1, and a moving chute is provided on the top of the base 1 and outside the housing 2 3. The interior of the moving chute 3 is installed with a shading plate 4 through bearing rotation, a cleaning device 44 is installed on the top of the housing 2, and a shading tube 8 is fixedly installed on the top of the base 1 and inside the housing 2, and the inner wall of the shading tube 8 And be positioned at the position close to the middle and be fixedly installed with the display negative film 9, the top of the base 1 and be positioned at the position in the middle are fixedly installed with the collection camera 10, the inner wall of the top of the housing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap