Underground mine medium-length hole blasting well formation technology

A deep hole blasting technology, applied in blasting, shaft equipment, mining equipment, etc., can solve the problems of huge construction machinery and equipment, limited application prospects, and high construction costs, so as to reduce manual workload, ensure safety, and save construction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

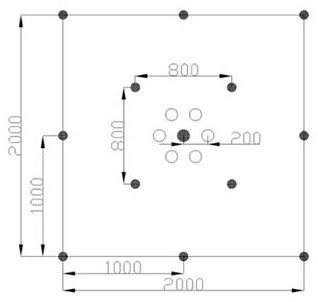

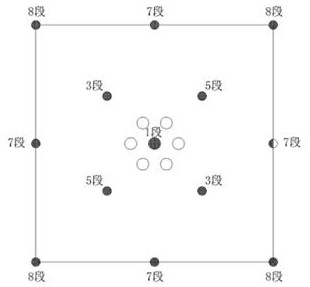

[0015] Such as Figure 1-2 As shown, under the condition that the rock condition of the raised well blasting mine operated is simple, the present invention discloses a deep hole blasting well forming technology in an underground mine. , when one charging hole is arranged in the center of the patio by the middle-hole trolley, 6 empty holes are arranged in a hexagonal shape around the central charging hole, and the distance between the central charging hole and the empty hole is 200 mm. Two rows of peripheral charging holes are arranged on the upper side, and the distance between the inner row of peripheral charging holes is 800 mm, which is arranged in a square with 4 vertices, and the distance between the outer row of peripheral charging holes is 1000 mm, which is also arranged in a square with 4 vertices.

Embodiment 2

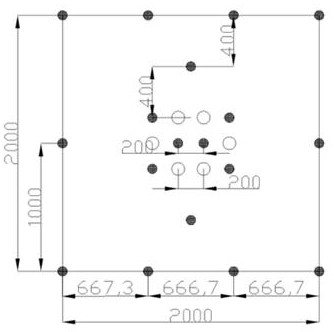

[0017] Such as Figure 3-4 As shown, in the case of complex rock conditions in the raised well blasting mine, the invention discloses a deep hole blasting well formation technology in underground mines. The raised well section specification is 2.0mX2.0m, and the raised well height ranges from 6m to 11m , when two charging holes are arranged in the center of the cutting patio by the middle hole trolley, the distance between the two central charging holes is 200mm, 6 empty holes are arranged around the central charging hole, and 4 peripheral devices are arranged at the four corners of the empty holes. Charge holes, the distance between adjacent empty holes is 200mm, and the distance between adjacent empty holes, the central charging hole and the surrounding charging holes is 200mm, and two peripheral charging holes are arranged on the center line of the patio section, and the surrounding charging holes on the center line The distance between the charge hole and the empty hole is 40

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap