Autotransformer step-down control system based on PLC

A technology of autotransformer and control system, which is applied in the field of transformer control, can solve problems such as autotransformer overheating, reduced starting reliability, unfavorable intermediate relay, etc., and achieves the effects of stable operation, advanced design concept and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

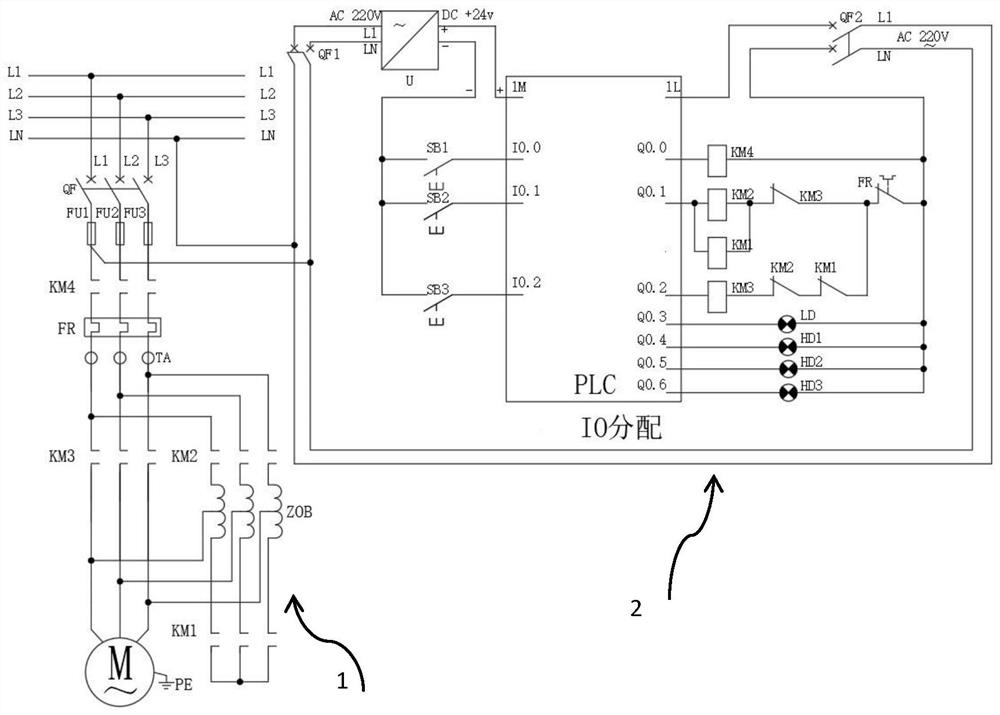

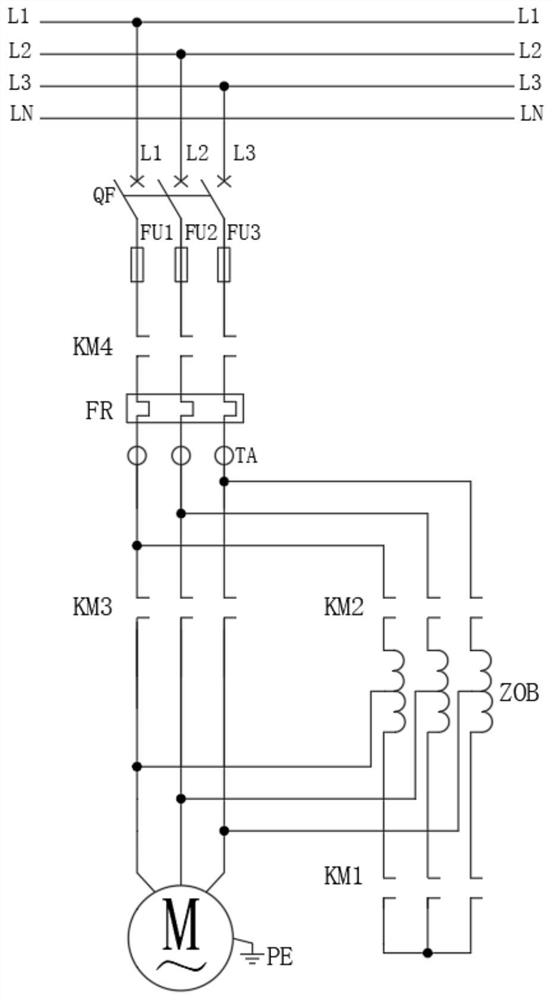

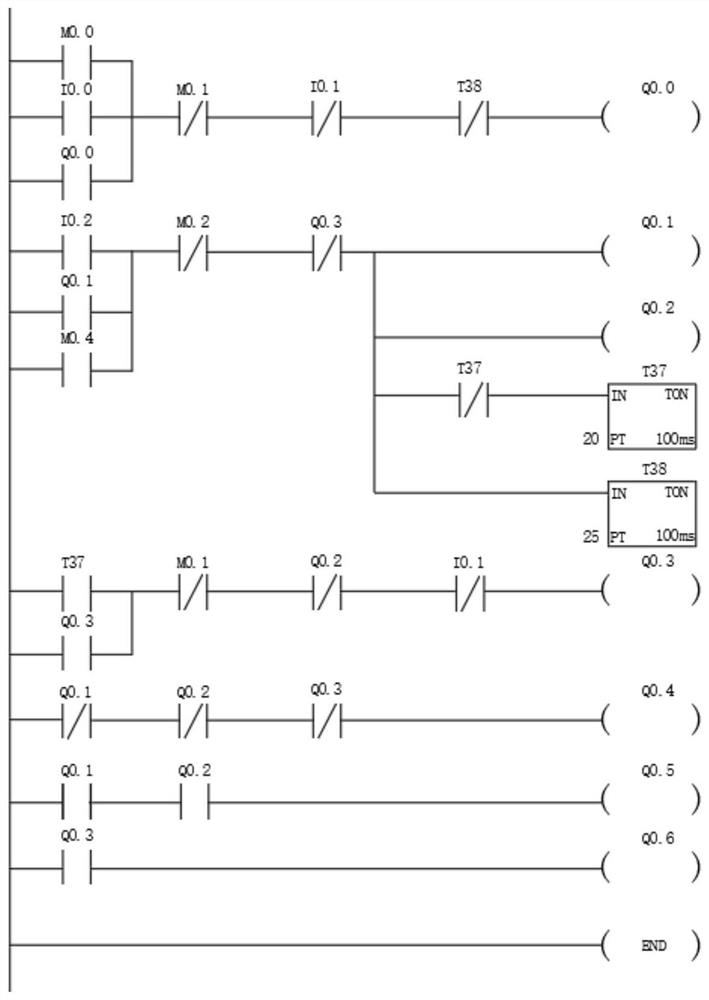

[0028] Please refer to the attached Figure 1-5 , the present invention provides a PLC-based autotransformer step-down control system, the system includes a main power circuit 1 and a control loop 2, wherein the main power circuit 1 is composed of a main power switch QF, a motor M, a fuse FU1, a fuse FU2, fuse FU3, main circuit AC contactor KM4, motor integrated protector FR, current transformer TA, full-voltage operation AC contactor KM3, step-down operation AC contactor KM2, star-point short-circuit AC contactor KM1 and automatic Composed of coupling transformer coil ZOB; the three terminals of the motor M are respectively connected to three live wires L1, L2, L3, and the three live wires L1, L2, L3 between the motor M and the main power switch QF are connected in series with full-voltage running AC Contactor KM3, current transformer TA, motor integrated protector FR, main circuit AC contactor KM4, fuse FU1, fuse FU2, fuse FU3; the first end of the autotransformer coil ZOB is s

Embodiment 2

[0033] Based on Example 1, as attached Figure 1-5 , the system works as follows:

[0034] The main circuit AC contactor KM4 is used to provide power supply for the whole set of circuits, and is used to supply power to the main power circuit 1 in the present invention. That is, close the main circuit AC contactor KM4 before starting, otherwise the main power circuit 1 and control circuit 2 of the entire system will be without power.

[0035] In addition, the PLC internal relay is used to monitor whether the full-voltage running AC contactor KM3 is closed, to prevent star-point short-circuiting of the AC contactor KM1, step-down running AC contactor KM2 jamming or contact welding, and poor contact of the auxiliary contact. And the protection measures that cause the autotransformer to run in the starting state all the time. In order to prevent such accidents, there is a time difference in the programming of the PLC, and the timer starting with the letter "T" inside the PLC is use

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap