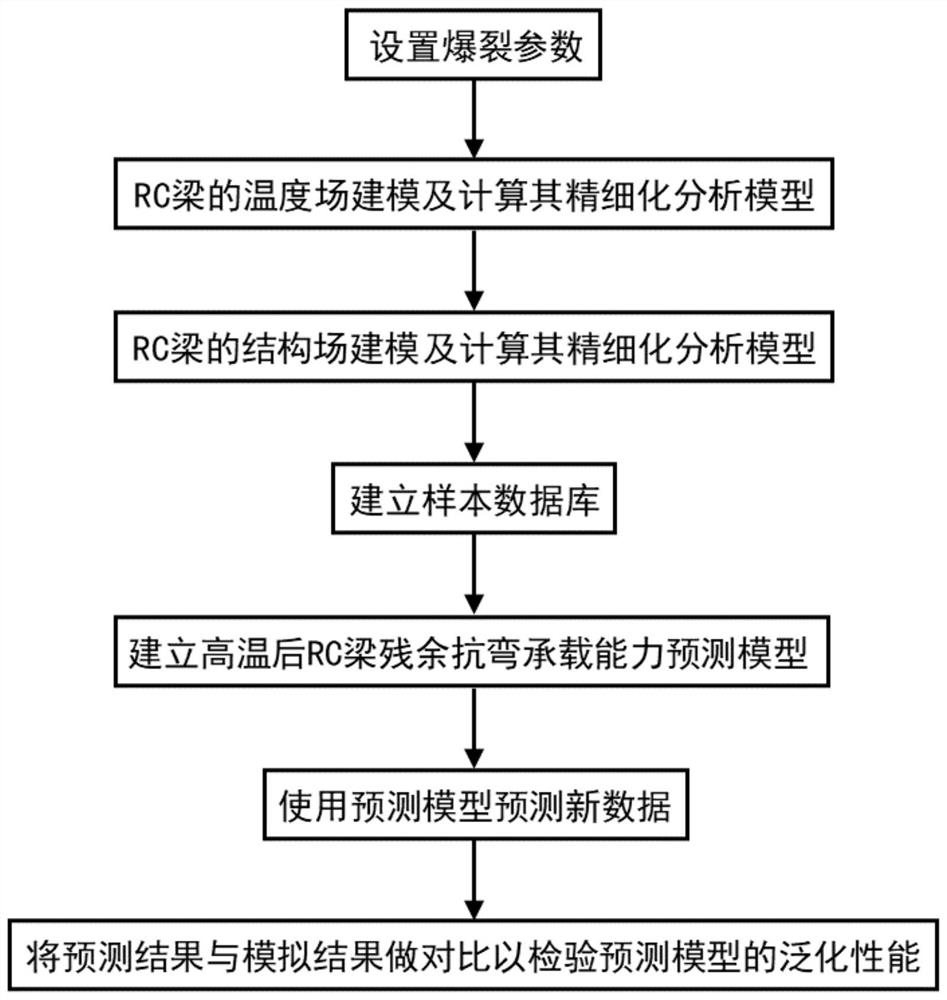

Method for predicting residual flexural capacity of RC beam considering high-temperature bursting of concrete

A prediction method and high temperature bursting technology, applied in geometric CAD, special data processing applications, instruments, etc., can solve the problems of difficult to achieve accurate prediction, the finite element model is not fine enough, and the influence law of structural bearing capacity is unclear, etc., and achieve good accuracy. Degree and reliability, universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Step 1. Establishing the constitutive relationship considering burst parameters and steel-concrete bond-slip, using ABAQUS software to establish a refined analysis model for RC beams;

[0126] In this embodiment, the fire time of the RC beam is set to be 120min, the burst depths are respectively 5mm, 10mm, 15mm, 20mm, and 25mm, and the burst area ratios are respectively 15%, 27%, 51%, 75%, and 100%. The location is within 1m of the mid-span of the bottom surface of the RC beam;

[0127] The modeling and calculation of the temperature field model of the RC beam in Step 1 is specifically:

[0128] (1) The RC beam adopts siliceous concrete with a strength grade of C35. The total length of the beam is 3000mm, and the distance between the center of the support and the end of the beam body is 100mm. The cross-sectional size of the beam is 250mm×400mm, the thickness of the concrete cover is 30mm, and the loading position is at the third bisection point of the beam. The bursting

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap