Energy-saving and environment-friendly high-voltage wire automatic rapid feeding and arranging structure

A high-voltage wire, fast-feed technology, used in overhead line/cable equipment, transportation of filamentous materials, thin material handling, etc., can solve problems such as difficult to adjust feed lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

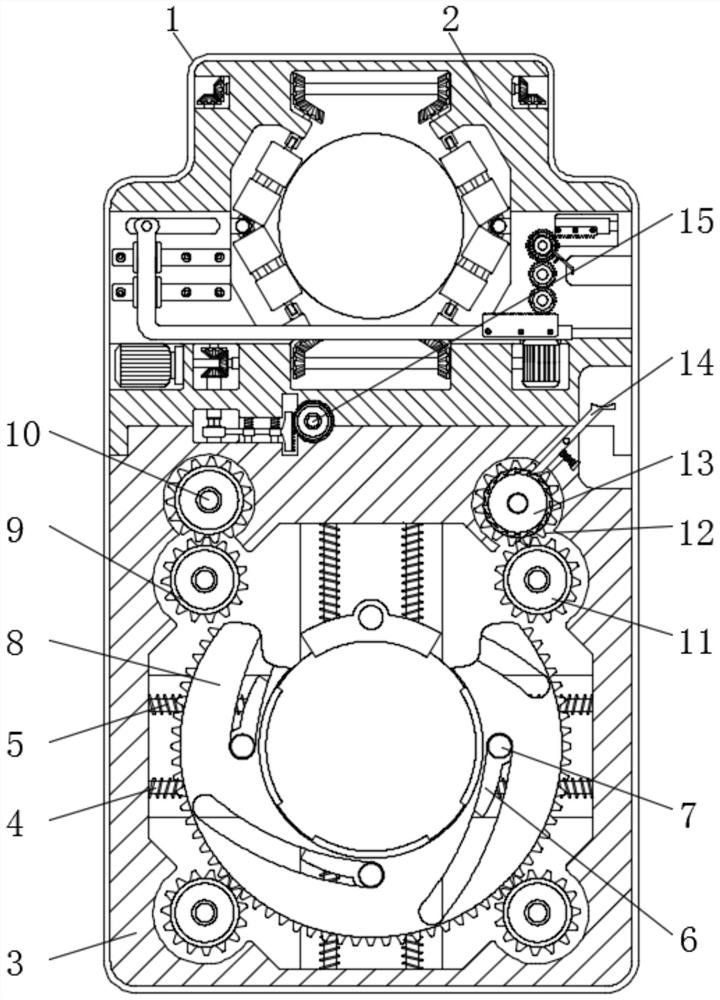

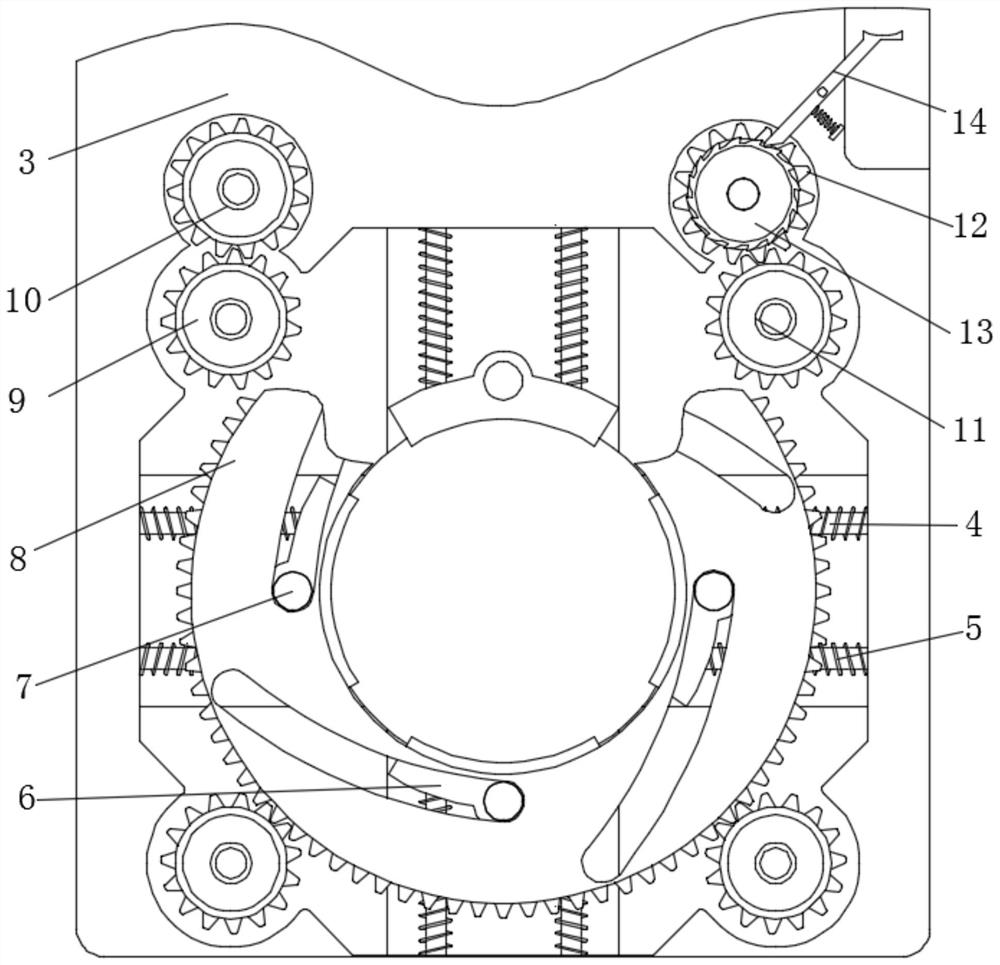

[0024] see Figure 1-2 with Figure 4 , an energy-saving and environment-friendly high-voltage electric wire automatic fast-feed cable structure, including a frame 1, how the frame 1 is fixedly connected with a feed mechanism 2, and the front of the frame 1 is fixedly connected with a clamping frame 3, and the clamping frame The inside of 3 is fixedly connected with a dovetail slide rail adapted to the clamping plate 6, the inside of the clamping frame 3 is provided with a circular through hole adapted to the clamping guide post 4, and the inside of the clamping frame 3 is provided with a The connecting plate 6 is adapted to the rectangular chute, the inside of the clipping frame 3 is provided with a circular through hole, the inside of the clipping frame 3 is slidingly connected with the clipping guide post 4, and the outside of the clipping guide post 4 is sleeved with a return spring 5. The end of the clamping guide post 4 away from the clamping frame 3 is fixedly connected t

Embodiment 2

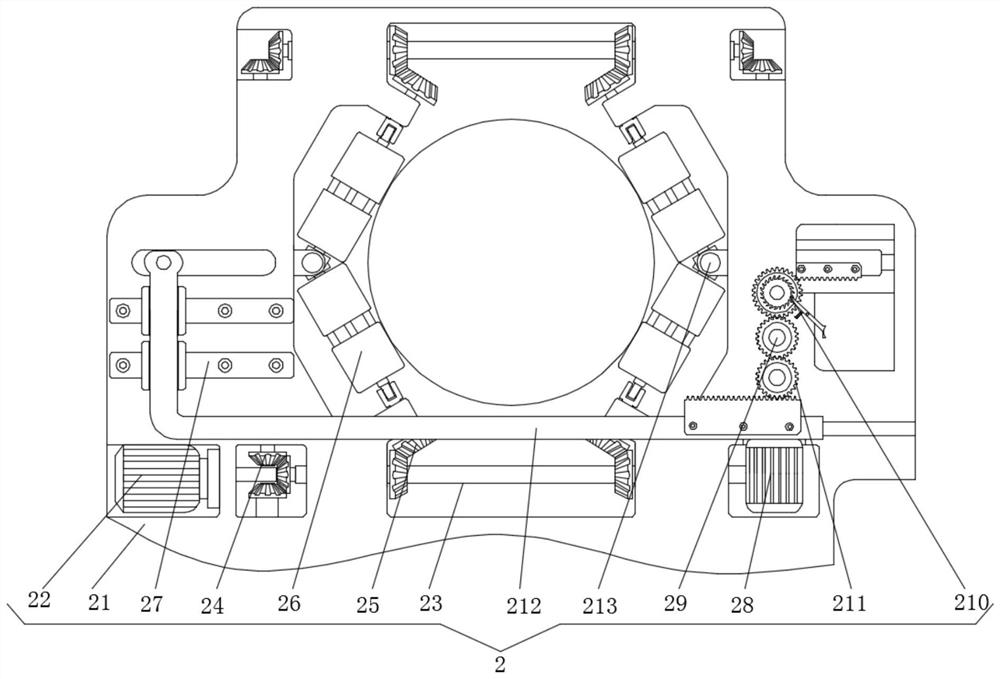

[0026] see figure 1 with image 3 , an energy-saving and environment-friendly high-voltage wire automatic fast-feed cable structure, including a frame 1, how the frame 1 is fixedly connected with a feed mechanism 2, the feed mechanism 2 includes a feed frame 21, and the inside of the feed frame 21 A feed motor 22 is fixedly connected, and the right side of the feed motor 22 is rotatably connected with a transmission shaft 23, and the inside of the feed frame 21 is rotatably connected with a connecting shaft 24 and a feed runner 25, and the feed runner 25 is fixed Connected with feed roller 26, feed roller 26 is made up of two sections of rollers and connecting guide posts, between the two sections of rollers there is a connection guide post for sliding connection, the bottom and top of the two sections of rollers are respectively connected to the feed runner 25 and One end of the connecting slide bar 213 is rotationally connected, the front of the feed frame 21 is fixedly connec

Embodiment 3

[0028] see Figure 1-4, an energy-saving and environment-friendly high-voltage wire automatic fast-feed cable structure, including a frame 1, how the frame 1 is fixedly connected with a feed mechanism 2, the feed mechanism 2 includes a feed frame 21, and the inside of the feed frame 21 A feed motor 22 is fixedly connected, and the right side of the feed motor 22 is rotatably connected with a transmission shaft 23, and the inside of the feed frame 21 is rotatably connected with a connecting shaft 24 and a feed runner 25, and the feed runner 25 is fixed Connected with feed roller 26, feed roller 26 is made up of two sections of rollers and connecting guide posts, between the two sections of rollers there is a connection guide post for sliding connection, the bottom and top of the two sections of rollers are respectively connected to the feed runner 25 and One end of the connecting slide bar 213 is rotationally connected, the front of the feed frame 21 is fixedly connected with an a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap