Refrigerator laser coding system and control method thereof

A technology of laser marking and control methods, which is applied to laser welding equipment, manufacturing tools, household refrigeration devices, etc., can solve problems such as affecting the appearance, uneven refrigerator positions, and coding position deviations, and achieve the effect of avoiding inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Due to inertia, the position of the refrigerator may deviate when the refrigerator is running on the production line. When the refrigerator is coded, the fixing device will also tighten the refrigerator, and these external forces will also cause the refrigerator to shift. When people place the refrigerator on the assembly line, it is easy to cause position deviation. The refrigerator is relatively large, and it is not easy to detect the position deviation of a single refrigerator within the visual range of the human eye. These factors will cause the deviation of the coding position of the refrigerator.

[0051] figure 1 is a schematic diagram of a refrigerator 160 laser marking system 100 according to an embodiment of the present invention;

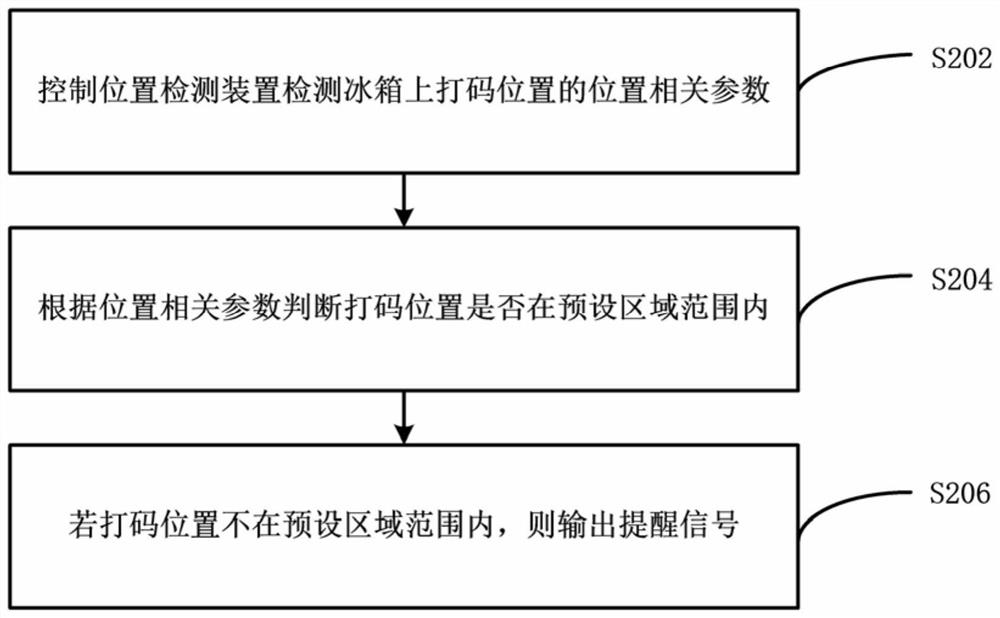

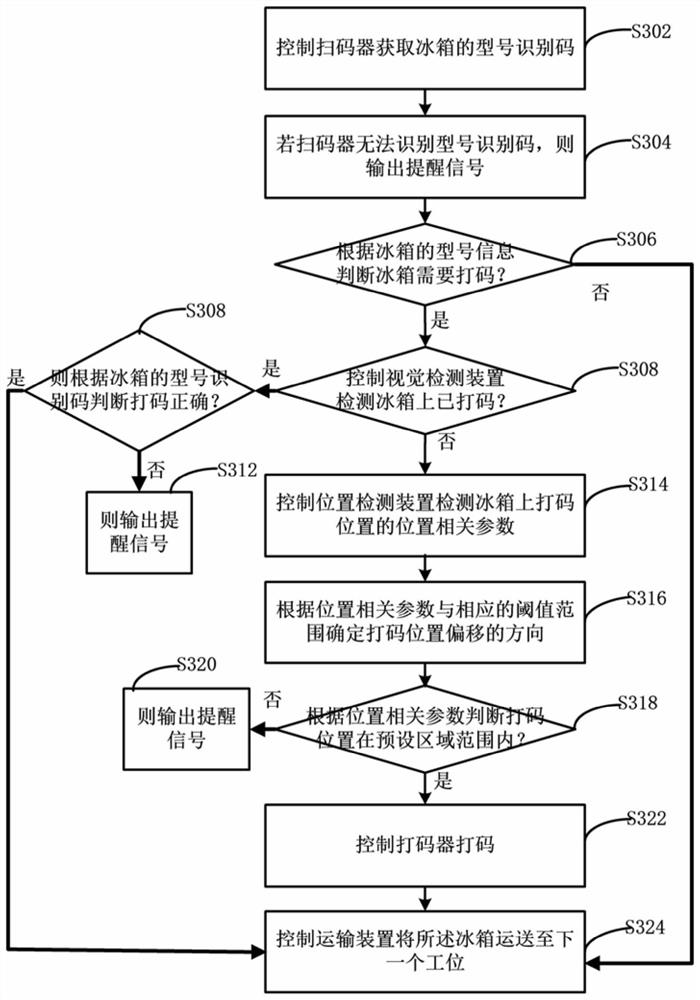

[0052] figure 2 It is a flow chart of the control method of the refrigerator 160 laser marking system 100 according to an embodiment of the present invention; image 3 It is a flow chart of the control method of the refrigerator

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap