Defrosting device and control method for refrigerator

A refrigerator and control panel technology, which is used in household refrigeration devices, defrosting, refrigerators, etc., can solve the problems of high energy consumption and slow defrosting speed of refrigerators, so as to improve heat absorption capacity, reduce energy consumption, and improve defrosting. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

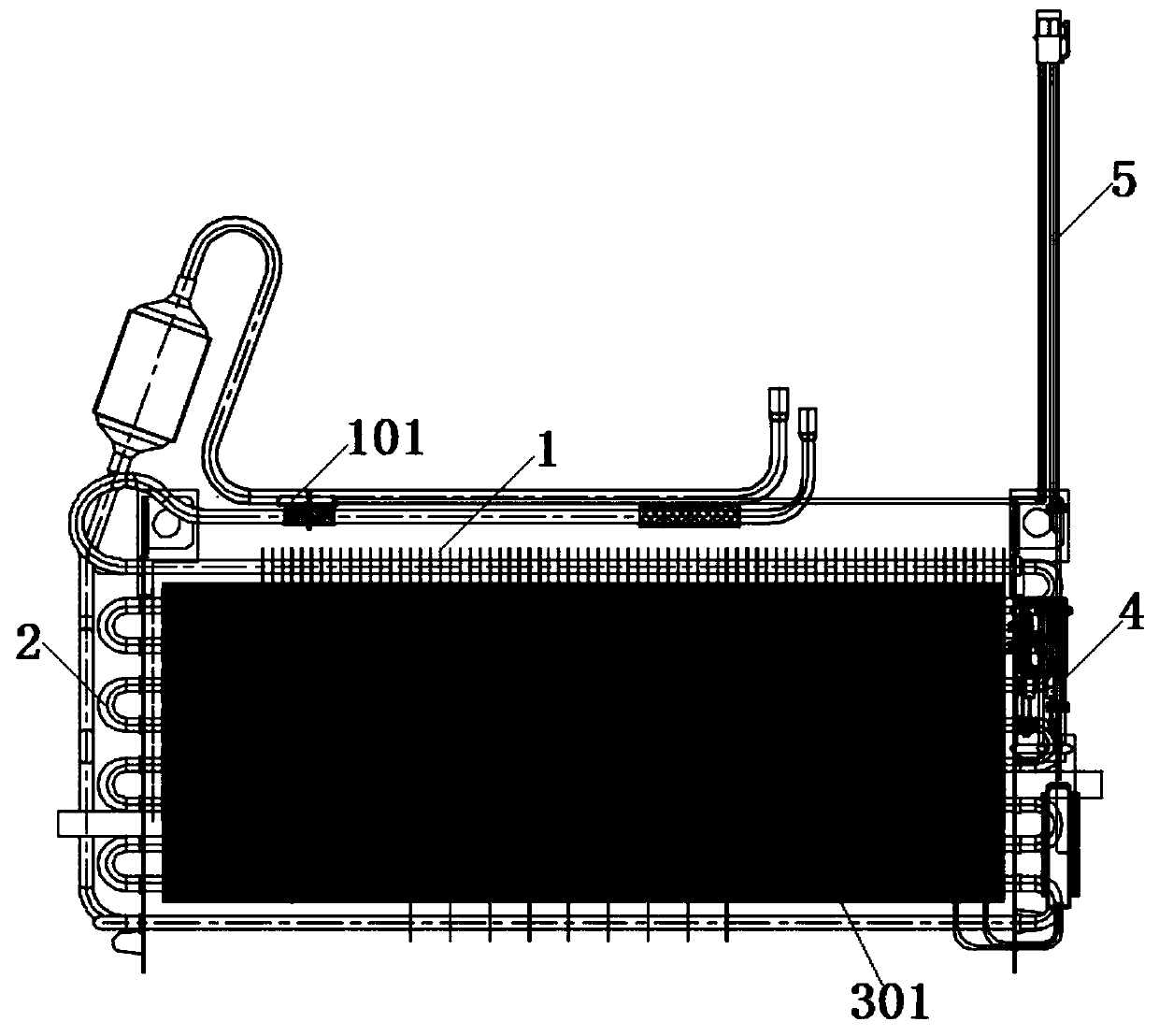

[0038] see figure 1 Shown, the present invention is a kind of refrigerator defrosting device, comprises evaporator; The thickness of the olefin heat dissipation paste layer is 5-15 μm or 7-10 μm, such as 10 μm.

[0039] A temperature sensor 101 is installed above the evaporator; a heat-resistant layer or support 3 is installed between the evaporator and the inner tank of the refrigerator, the support 3 can be a plate component, such as a glass plate or a ceramic plate, and the heat-resistant layer can be a resin layer . The heat-resistant layer or support 3 can be installed and fixed by screw connection or clamping.

[0040] The heat-resistant layer or support 3 is attached with a graphene heating film 301 towards one side of the evaporator, and the surface area of the graphene heating film 301 is greater than or equal to the projected area of the side of the evaporator, so that the heat generated by the graphene heating film 301 can cover the entire evaporation At the sam

Embodiment 2

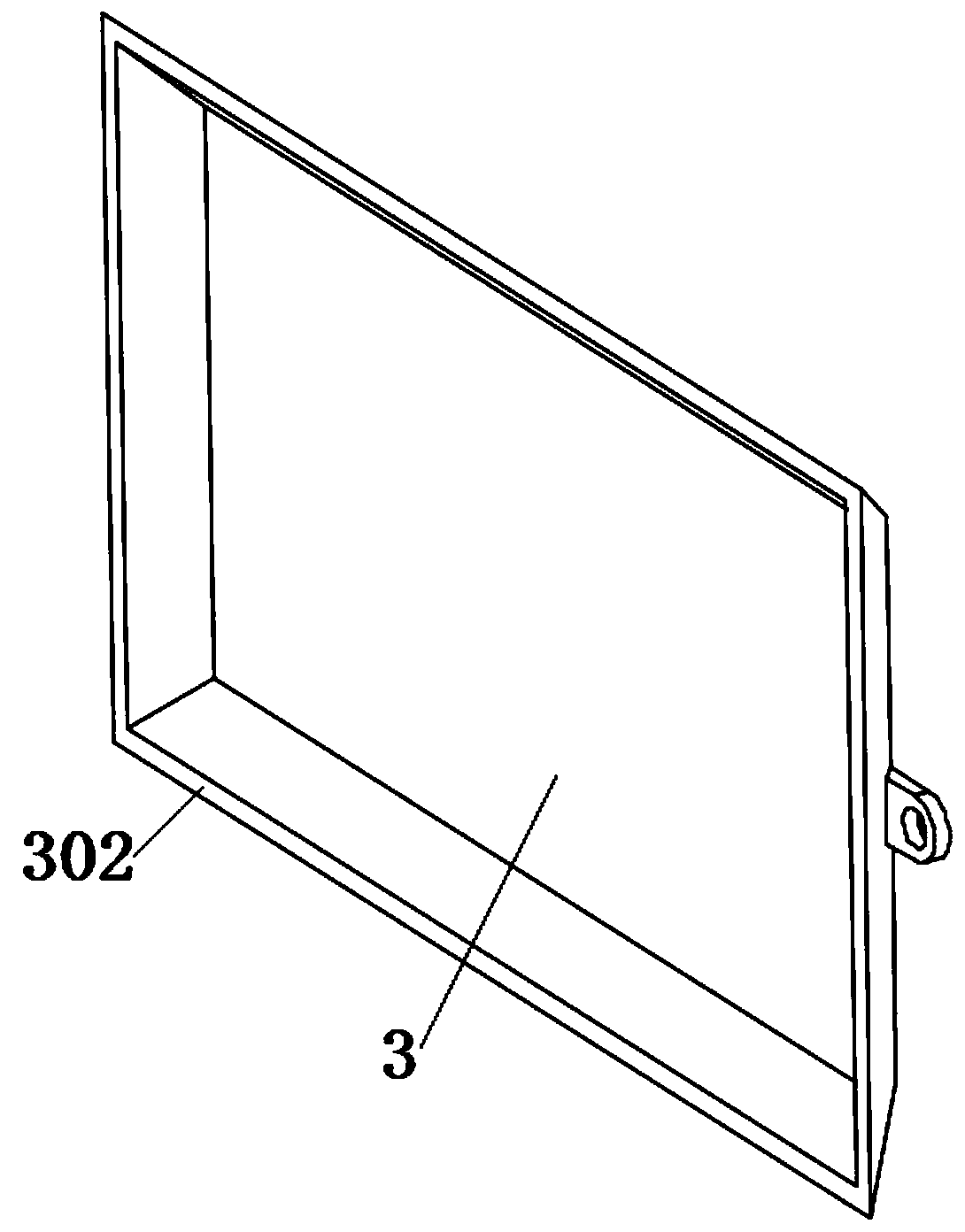

[0051] Such as figure 2 As shown, on the basis of the first embodiment, the support 3 is fixedly connected with a reflector 302 , and the reflector 302 can be a metal part or a plastic part, or an integrated structure with the support 3 .

[0052] The reflection cover plate 302 is a trumpet-shaped structure, and the flaring end of the reflection cover plate 302 faces the evaporator, and the constriction end is adapted to the sides around the support 3, and can be fixed by clamping or interference fit. The inner wall of the reflection cover plate 302 Attached with an infrared reflective film, the heat generated by the graphene heating film 301 can be reflected to the evaporator through the infrared reflective film. The horn-shaped structure allows the heat to converge on the evaporator after reflection, further improving the defrosting efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap