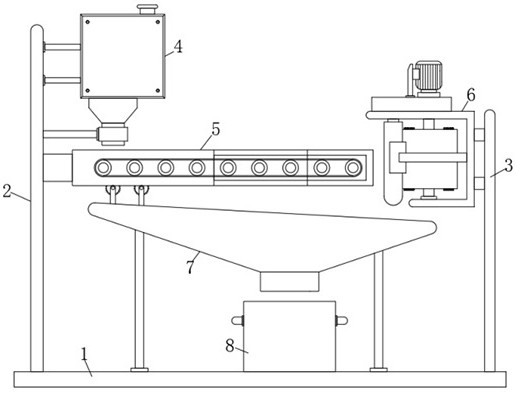

Electric power steel pipe milling waste treatment device

A technology for electric steel pipes and waste treatment, applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as scratches, achieve the effect of easy curling, and improve curling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

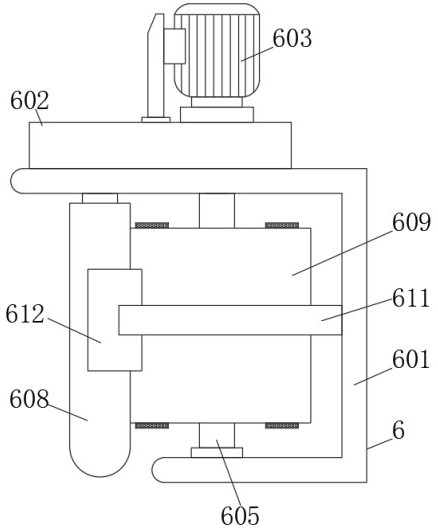

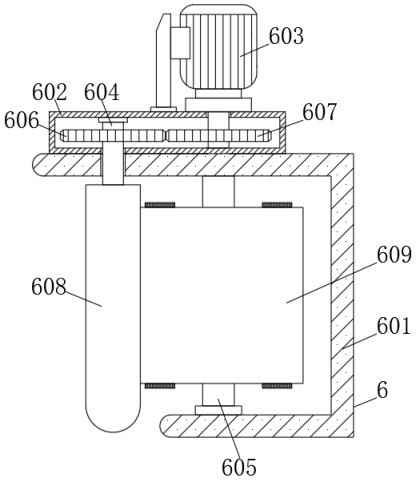

Method used

Image

Examples

Embodiment 2

[0043] A method for treating electric steel pipe milling waste, comprising the following steps:

[0044] Step 1: Pour the debris produced in the milling process of the electric steel pipe into the inside of the feeding box 401 through the feeding pipe 402, and the debris inside the feeding box 401 falls on the material guide through the feeding hopper 405 and the feeding pipe 406 On the belt 509, start the material guide motor 505 to drive the leftmost rotating rod 504 to rotate clockwise, and drive all the rotating rods 504 to rotate clockwise synchronously through the transmission assembly 507, and the debris falling on the material guide belt 509 will move from left to right. Conveying on the right;

[0045] Step 2: After the debris leaves the material guide belt 509, the curled debris falls down through the gap between the rotating rod 504 and the rotating rod 504, and the long section of debris continues to be conveyed along with the rotating rod 504, and the material guide

Embodiment 3

[0049] see Figure 9 As shown, the inner wall of the material guide frame 5 is also provided with a processor, and the processor is communicatively connected with a sampling module, a storage module, a temperature monitoring module, a power detection module and a transmission detection module.

[0050] When the curling or separation effect of the debris is not satisfactory, the factors causing the curling or separation effect of the debris are checked one by one through the temperature monitoring module, the power detection module and the transmission detection module.

[0051] After the debris falls in the material receiving box 8, the staff conducts a random inspection of the debris in the material receiving box 8. If the random inspection result is that the debris is unqualified, the sampling module and the processor send a temperature detection signal to the temperature monitoring module. After receiving the temperature detection signal, the temperature monitoring module dete

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap