Semi-automatic electronic chip visual inspection equipment

An electronic chip, visual inspection technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of inaccurate inspection results, chip surface errors, inconvenient use, etc., and achieve the effect of accurate inspection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

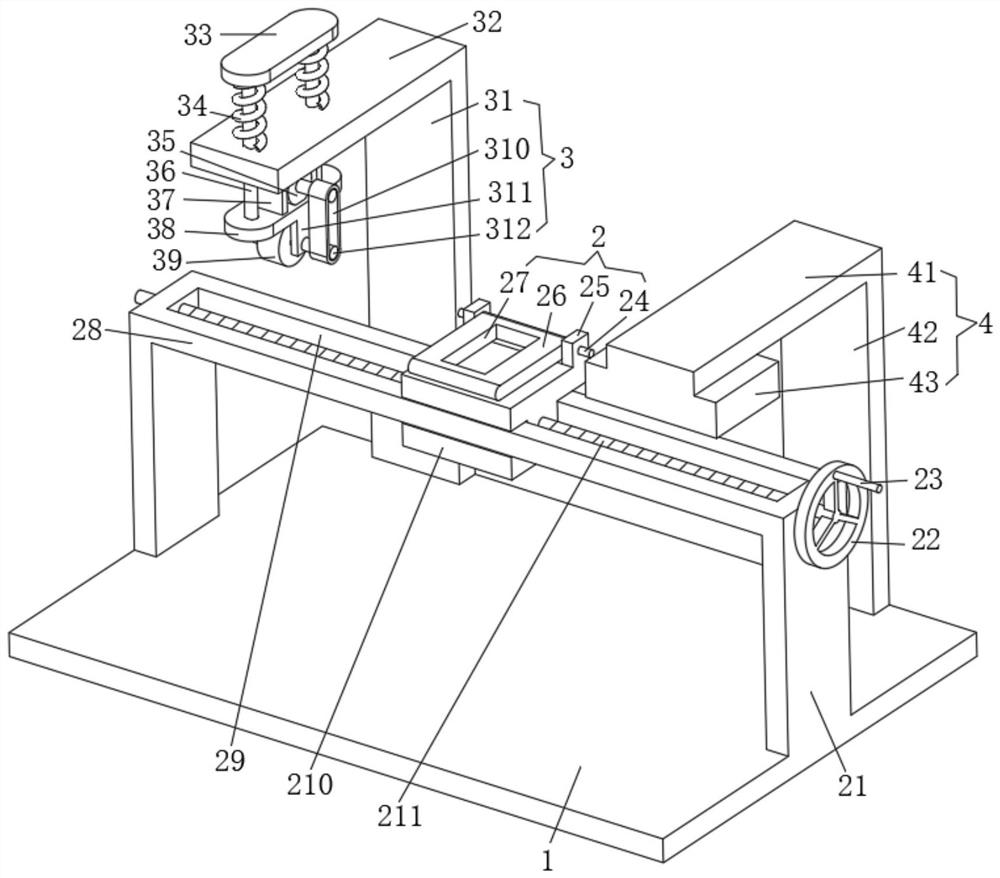

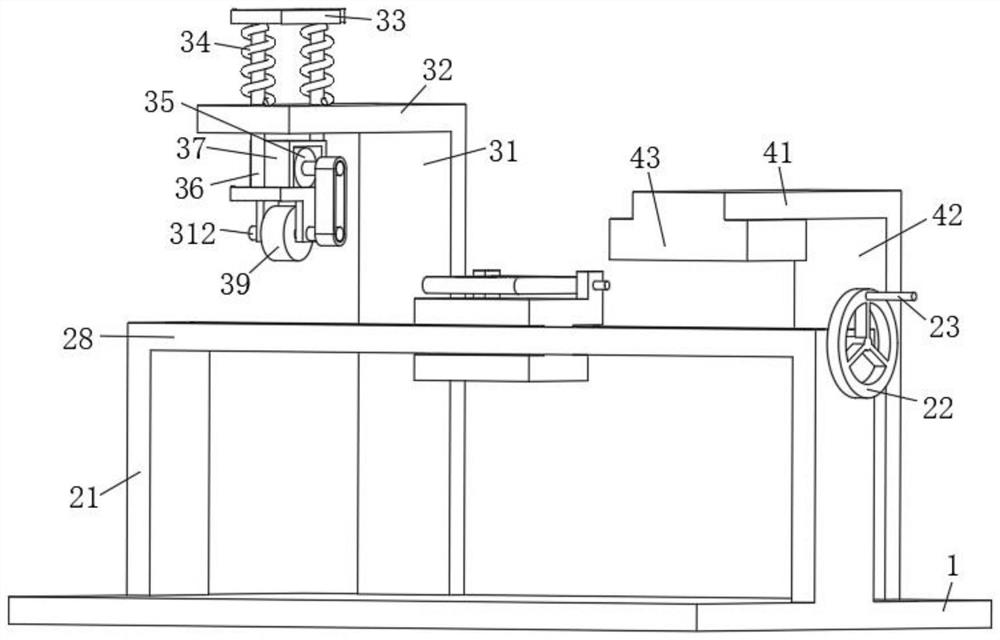

[0024] See Figure 1-2 This embodiment provides a technical solution: a semi-automatic electronic chip visual detection device, including a bottom plate 1, an electronic chip fixing unit 2, a chip surface cleaning unit 3, and a visual detection unit 4;

[0025] Backplane 1: is a rectangular;

[0026] Electronic chip fixing unit 2: includes a vertical support plate 12, a rotating shaft one 24, a support ear, a movable plate 26, a rectangular pass groove 27, a rectangular fixing plate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap