Soft measurement method for temperature in multi-component organic waste high-temperature gasifier

An organic waste and gasifier technology, applied in the energy industry and chemical engineering fields, can solve the problems of loss of liquid organics, instability, unsuitability, etc., and achieve the effect of reducing time cost, high accuracy and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further elaborated and described below in conjunction with specific embodiments. The technical features of the various embodiments of the present invention can be combined correspondingly on the premise that there is no conflict with each other.

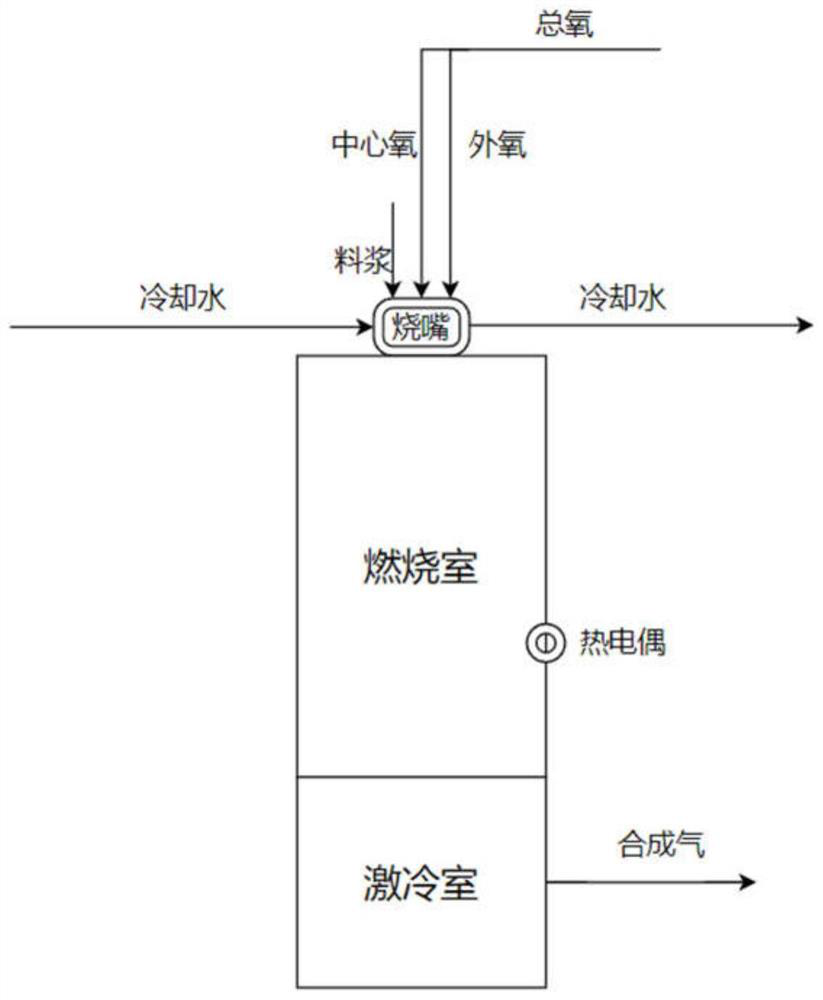

[0068] like figure 1 As shown, it is a schematic diagram of the multi-component organic waste co-processing process. The present invention selects the cooling water inlet flow rate, cooling water outlet flow rate, cooling water inlet temperature, cooling water outlet temperature, cooling water pressure, and the temperature of the synthesis gas exiting the chilling chamber as Input variables, the selected characteristic variable data are all obtained by the automatic testing of the instrument in the actual production line. Compared with the slurry concentration, calorific value and other data that need to be measured in the laboratory after sampling, the selected input variable data is easy to obtain

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap