Method for monitoring average sand production rate of oil and gas well

A technology for oil and gas wells and rates, applied in surveying, earthmoving, wellbore/well components, etc., can solve the problems of complex processing system, low reliability, damage, etc., and achieve simple processing system, high equipment reliability, circuit simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be noted that the following detailed description is exemplary and intended to provide further explanation for the application, and unless otherwise specified, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs .

[0044] Example embodiments, however, can be embodied in various forms and should not be construed as limited to the examples set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of example embodiments to this disclosure technicians in the field. The described features may be combined in any suitable way in one or more embodiments.

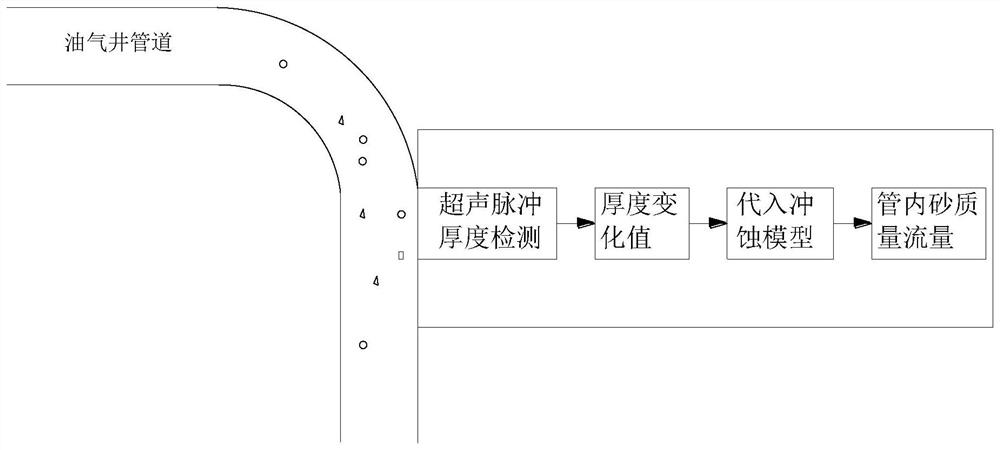

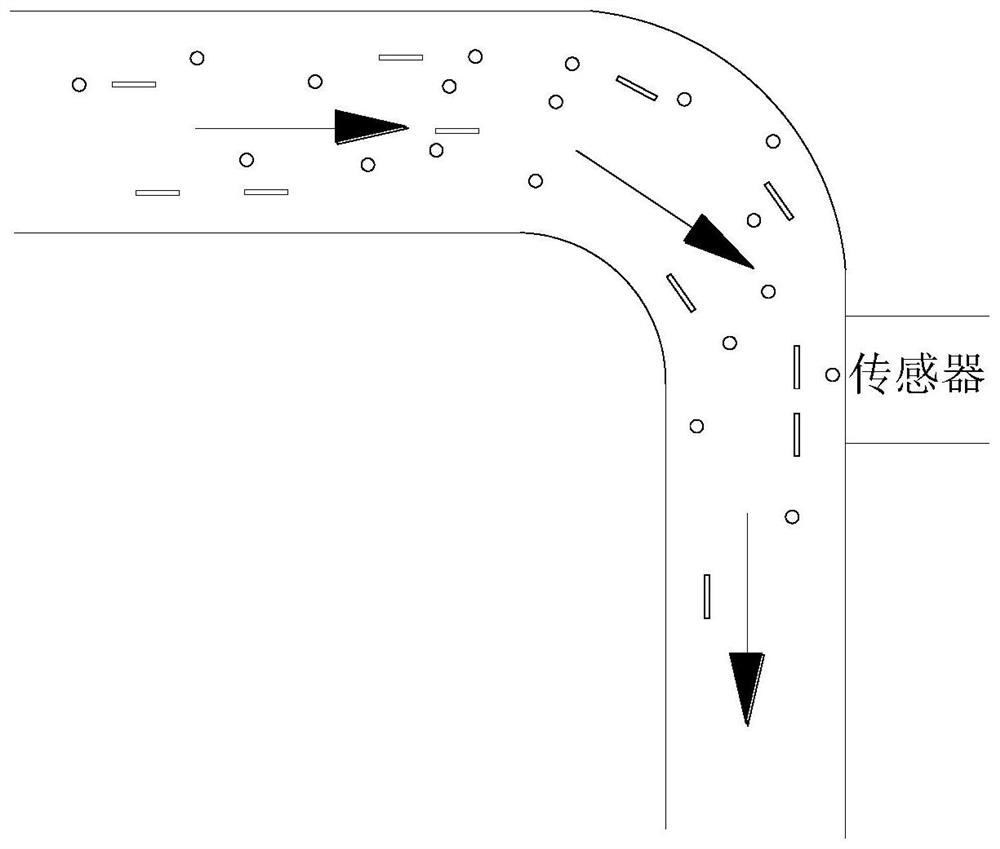

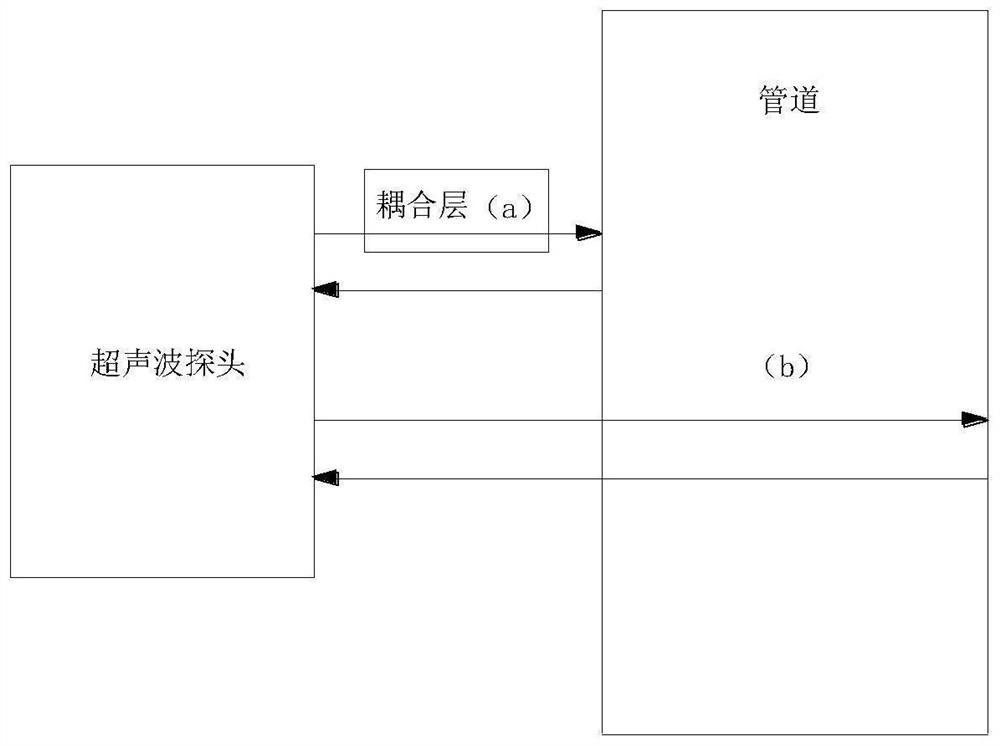

[0045] This example embodiment provides a method for monitoring sand production in oil and gas wells, which can be applied to sand production monitoring in oil and gas wells. refer to figure 1 As shown in, the above-menti

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap