Control device of hot-line work robot

A live working and control device technology, applied in the field of electric power engineering, can solve the problems of power consumption, easy to be bumped and carried, and the handle rod is easy to occupy a large space, so as to reduce power consumption, avoid rotation and reduce volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. The embodiments described below with reference to the accompanying drawings are exemplary, only used to explain the present invention, and should not be construed as a limitation of the present invention.

[0028] The embodiments of the present invention will be described below based on the overall structure of the present invention.

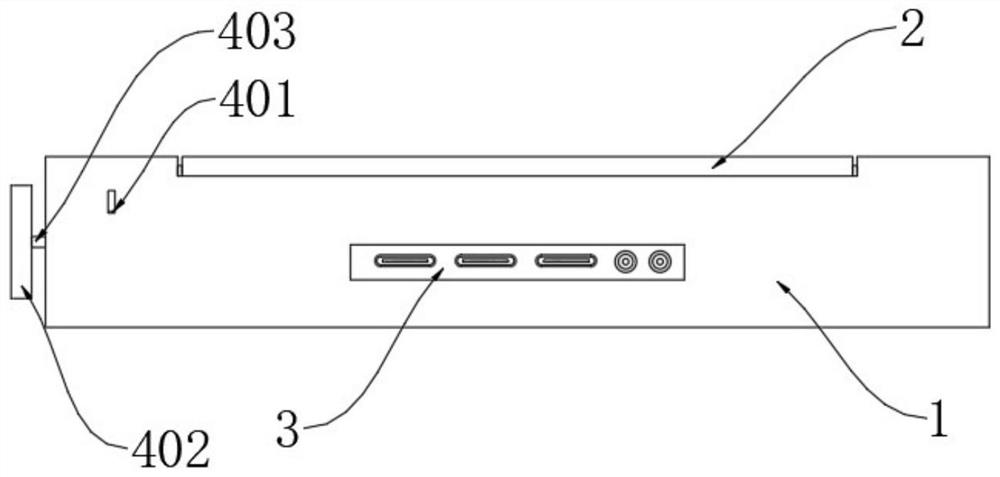

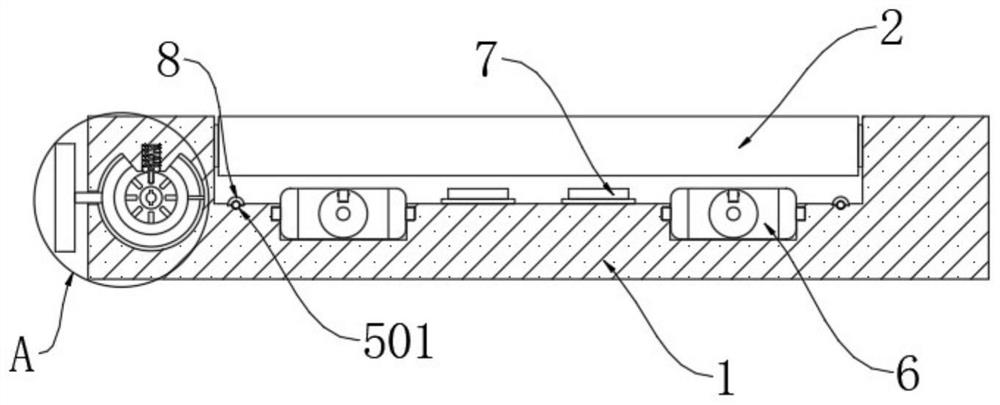

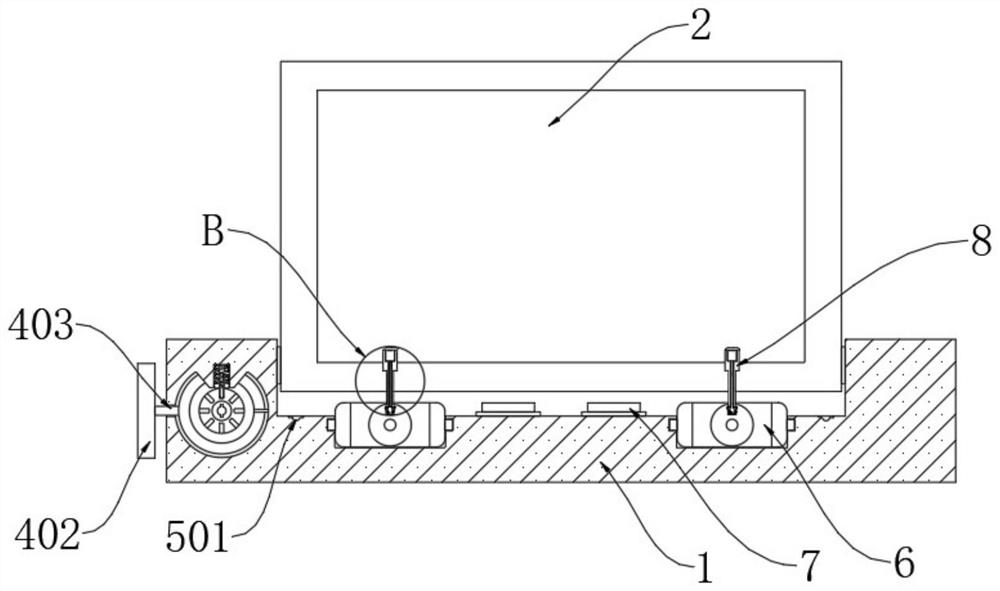

[0029] A control device for a live working robot, such as figure 1 , 2 , 3, 4, 5 and 6, it includes a remote control 1 and a handle bar 8, and the handle bar 8 is provided with a disassembly assembly 5 inside.

[0030] Specifically, the disassembly and assembly assembly 5 further includes a control block 502, the bottom of the control block 502 is connected with a pull rope 503, one end of the pull rope 503 is connected with a limit block

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap