Magnetic adsorption separation device

A separation device and magnetic adsorption technology, used in transportation, packaging, motor vehicles, etc., can solve the problems of narrow application scope and poor versatility, and achieve the effects of improving versatility, preventing wires from flying around, and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

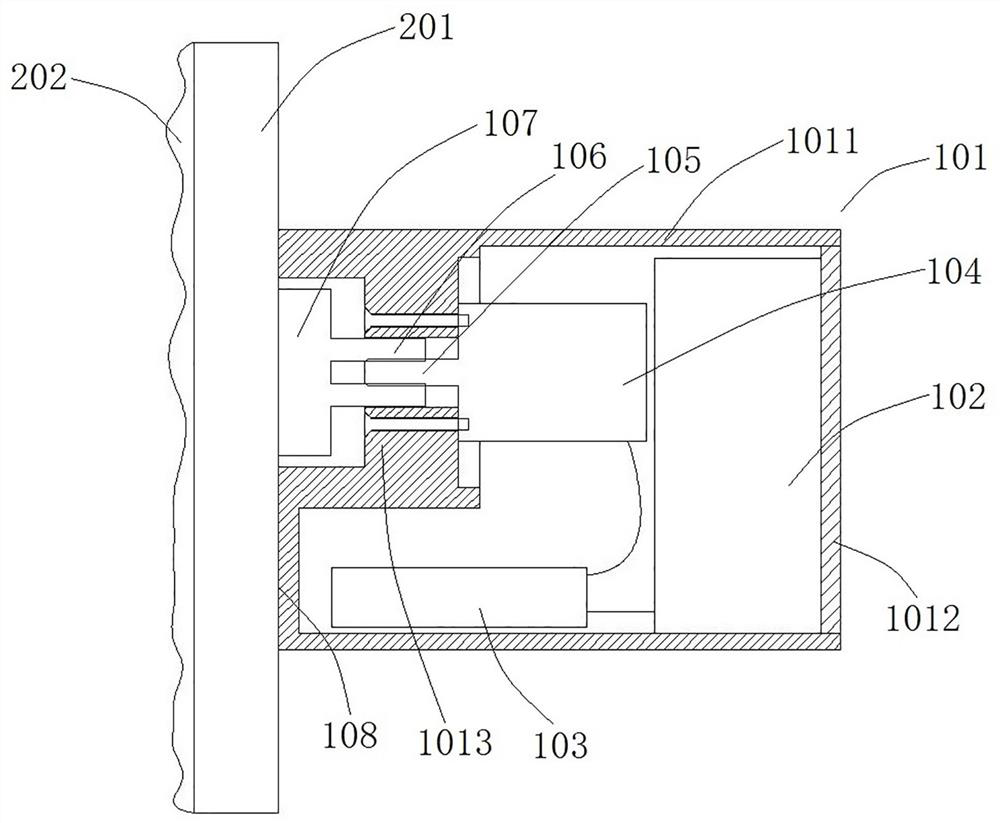

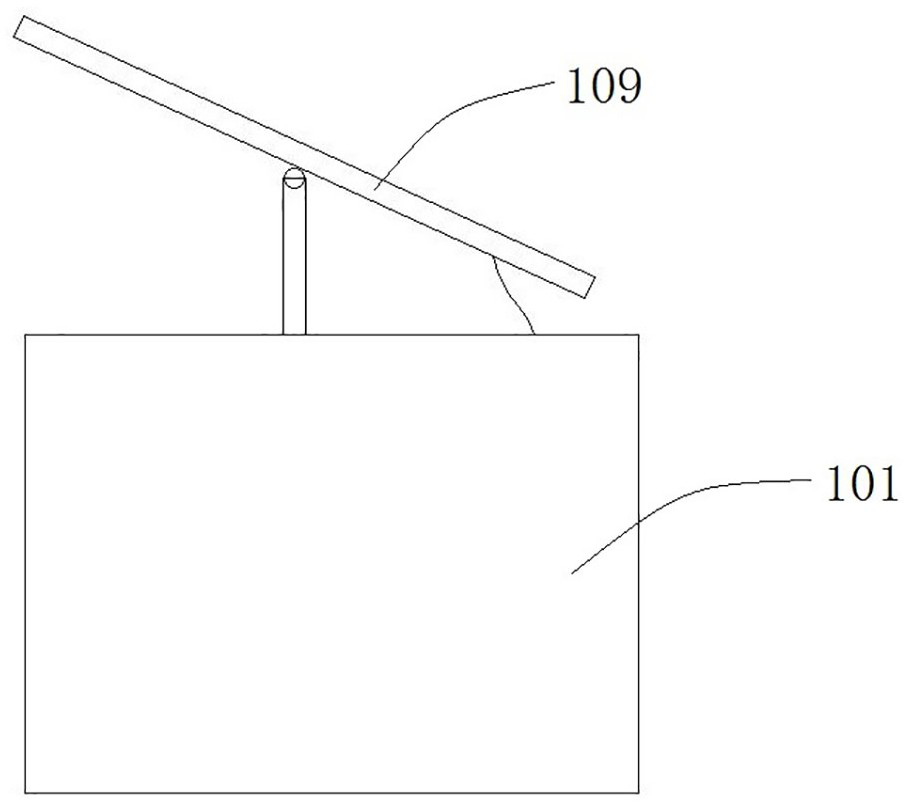

[0041] like figure 1 As shown, the magnetic adsorption separation device provided in this embodiment can be fixed on the surface of the fixed object and realize remote remote separation when separation is required.

[0042] The magnetic adsorption separation device includes a support base 101, and the support base 101 serves as an installation base for each component. The support base 101 includes a frame 1011 and a cover body 1012 packaged at one end of the frame 1011 . The cover body 1012 is separately fixed on the frame 1011 , specifically, a bolt connection method may be used. The magnetic adsorption separation device also includes a lead screw nut mechanism, which includes a motor 104 fixed on the frame 1011, and a lead screw 105 fixed on the output shaft of the motor 104. The lead screw nut mechanism also includes a lead screw 105 The mating nut 106 is guided and slidably assembled in the frame 1011 . Specifically, the frame 1011 includes along figure 1 The mounting wall

Embodiment 1

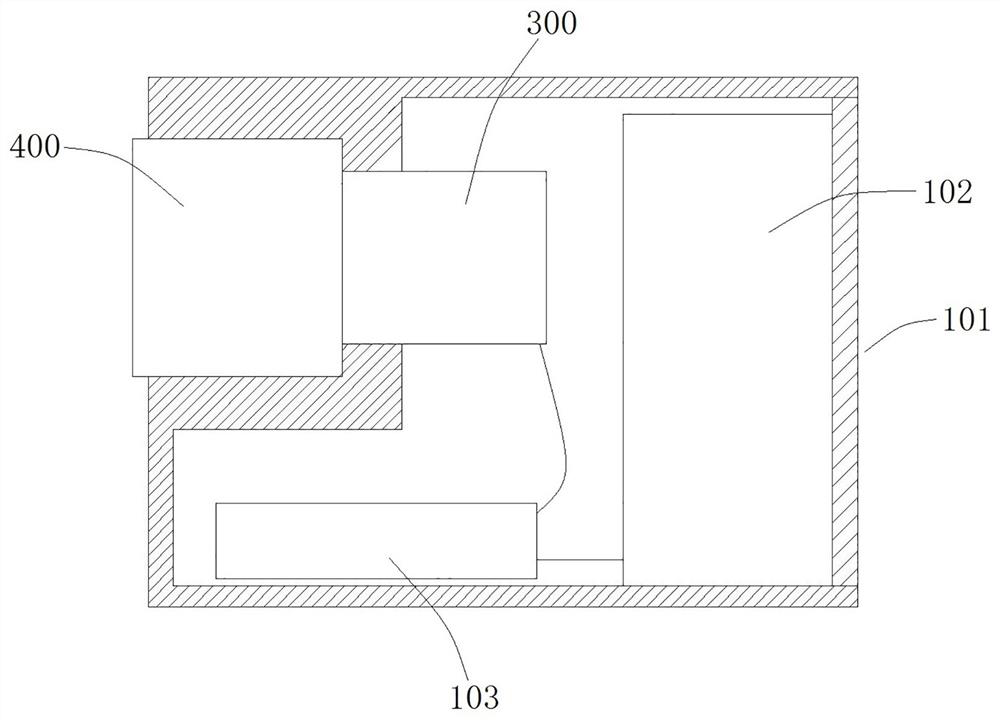

[0051] In Embodiment 1, both the permanent magnet and the driving member are located in the frame. In this embodiment, the permanent magnet and the driving member may be located outside the frame.

specific Embodiment 3

[0053] In Embodiment 1, the connecting structure is an adhesive layer disposed on the transition piece. In this embodiment, the form of the connection structure is changed according to the material and structural form of the fixed object. For example, the connecting structure is a hook fixed on the transition piece, and the hook can be hooked to the facade of the city wall, or it can be a vacuum suction cup, which can be adsorbed on the surface of the city glass curtain wall.

[0054] The shape and material of the transition piece can also be changed according to the actual situation. For example, the transition piece can be a block, and the material can be a metal material such as cobalt, nickel, or an alloy material.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap