Methods for treating deodorizer distillate

A technology of fraction and concentration zone, applied in the field of processing deodorant fraction, can solve the problems of time-consuming, residual solvent pollution, expensive processing steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

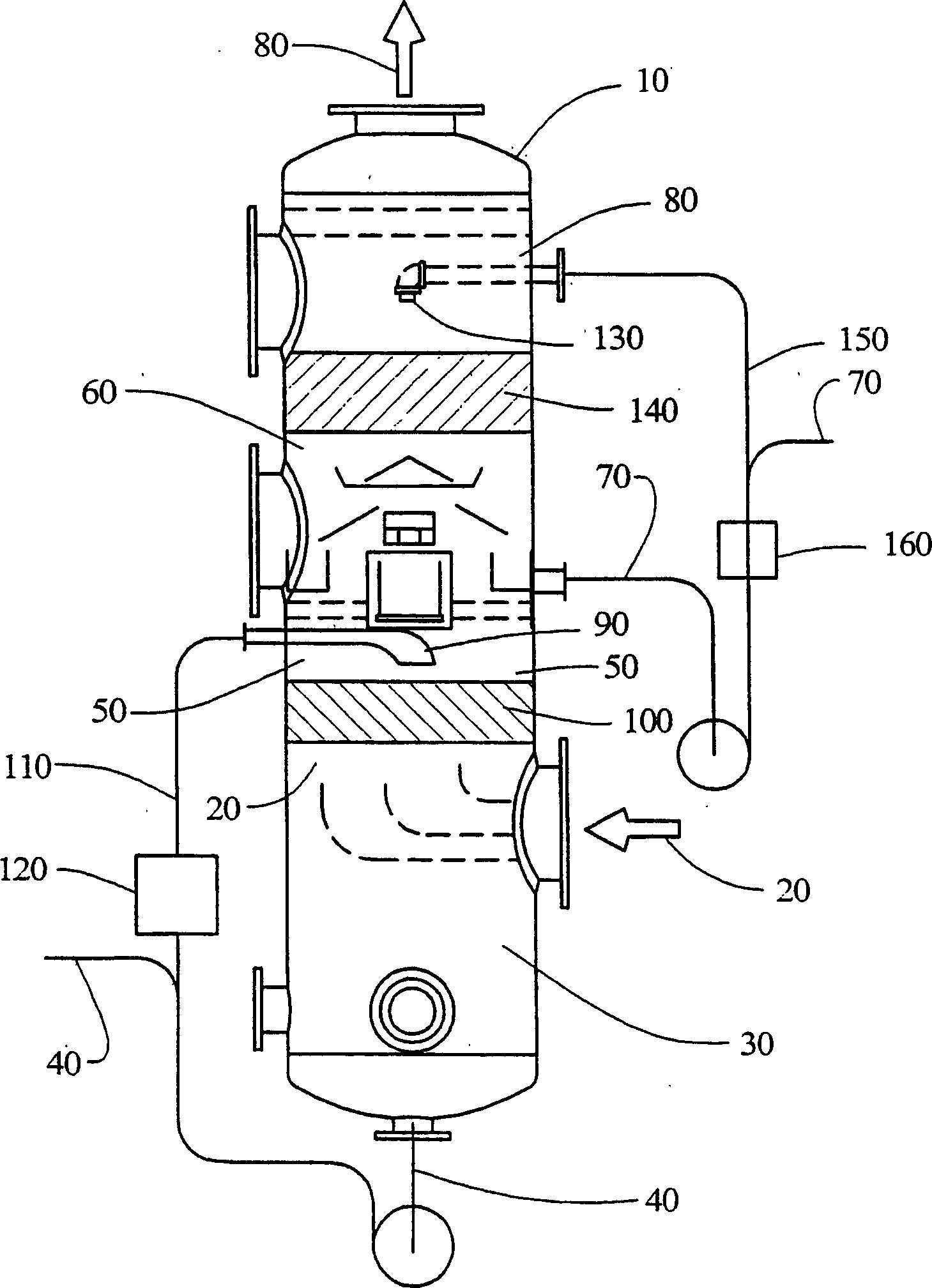

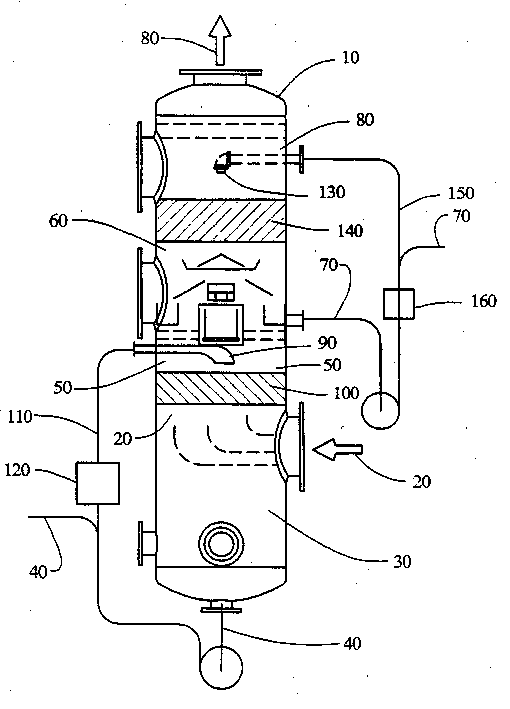

[0043] The evaporated fraction at about 300°F from the deodorization of organically extracted soybean oil flows at a flow rate of 250,000 lbs. Operate under pressure. The deodorant fraction contains about 50% by weight fatty acids, about 12% by weight tocopherols, about 14% by weight sterols, and about 24% by weight other components including oils.

[0044] The scrubbers consisted of cylindrical columns 14 feet high and 42 inches in diameter. The first enrichment zone is about 4 feet high and includes a fill zone with a vertical dimension of 15 inches. The packing zone within the first concentration zone contains a plurality of closely spaced serrated stainless steel discs provided with a plurality of holes. The nozzles extend into the first concentration zone above the fill zone. Vacuum is provided to the scrubber by Nash-kinema three-stage vacuum system or vacuum pump.

[0045] A first portion containing about 50 wt% of the evaporated fraction entering the first concentrati

Embodiment 2

[0054] The evaporated fraction at a temperature of about 330°F from the deodorization of conventionally refined soybean oil flows into the first enrichment zone of a scrubber at a flow rate of 250,000 lbs. Operate under the pressure of Hg. The deodorant fraction contains about 45% by weight fatty acids, about 15% by weight tocopherols, about 20% by weight sterols, and about 20% by weight other components including oils.

[0055] The scrubber consists of a cylindrical tower 18 feet high and 60 inches in diameter. The first enrichment zone is about 5 feet high and includes a fill zone with a vertical dimension of 24 inches. The packing zone in the first concentration zone contains a plurality of closely spaced serrated stainless steel discs with a plurality of holes. The nozzles extend into the first concentration zone above the fill zone. Vacuum is provided to the scrubber by Nash-kinema three-stage vacuum system or vacuum pump.

[0056] The first portion containing about 55 w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap