Electromagnetic valve drive circuit for engine

A solenoid valve driving and driving circuit technology, which is applied in engine control, machine/engine, electrical control, etc., can solve the problems of driving circuit driving ability, control accuracy, low duty cycle adjustment frequency, and complicated control software writing. , to achieve the effect of shortening the closing time, high precision of current control, and reducing the fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific circuit and working process of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

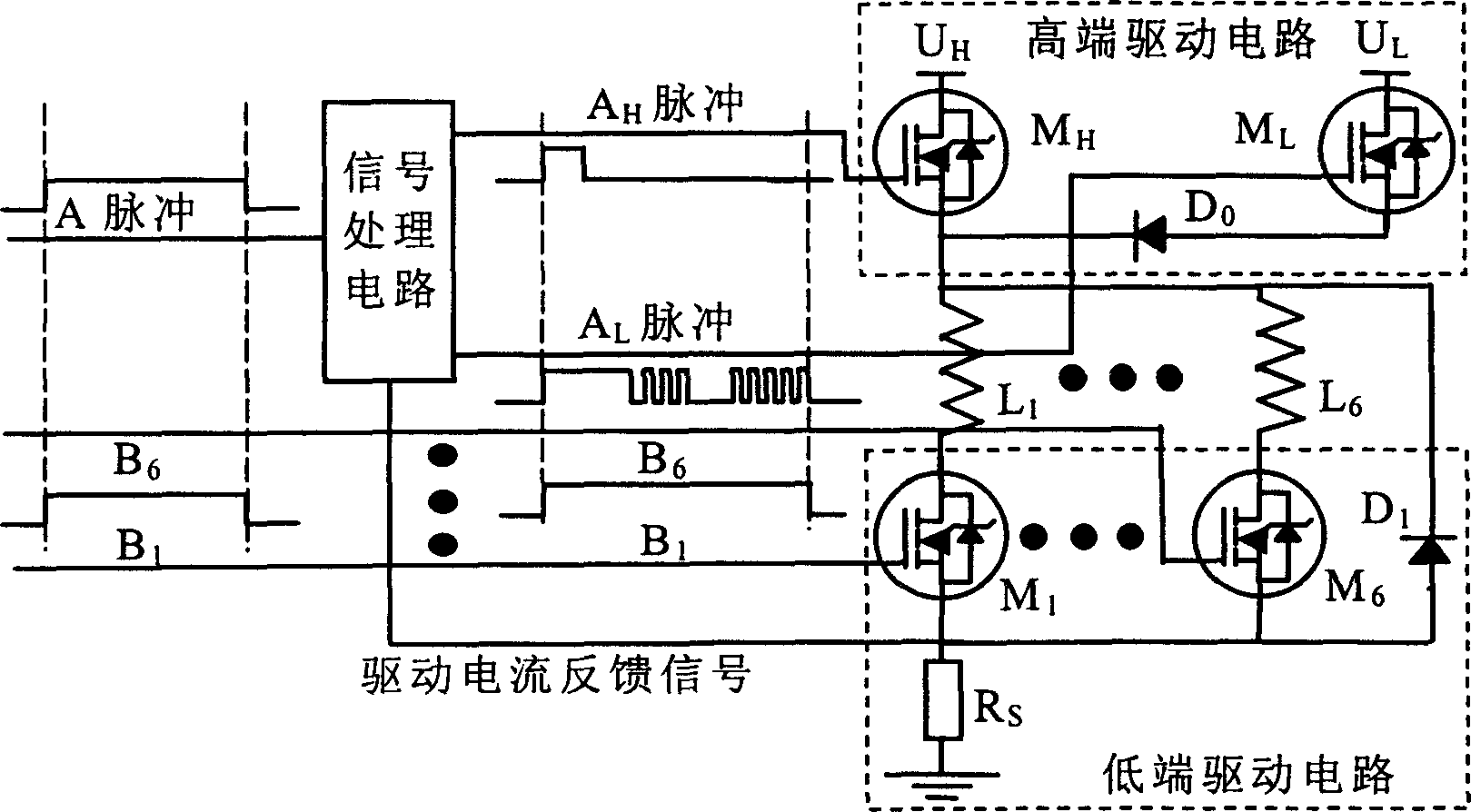

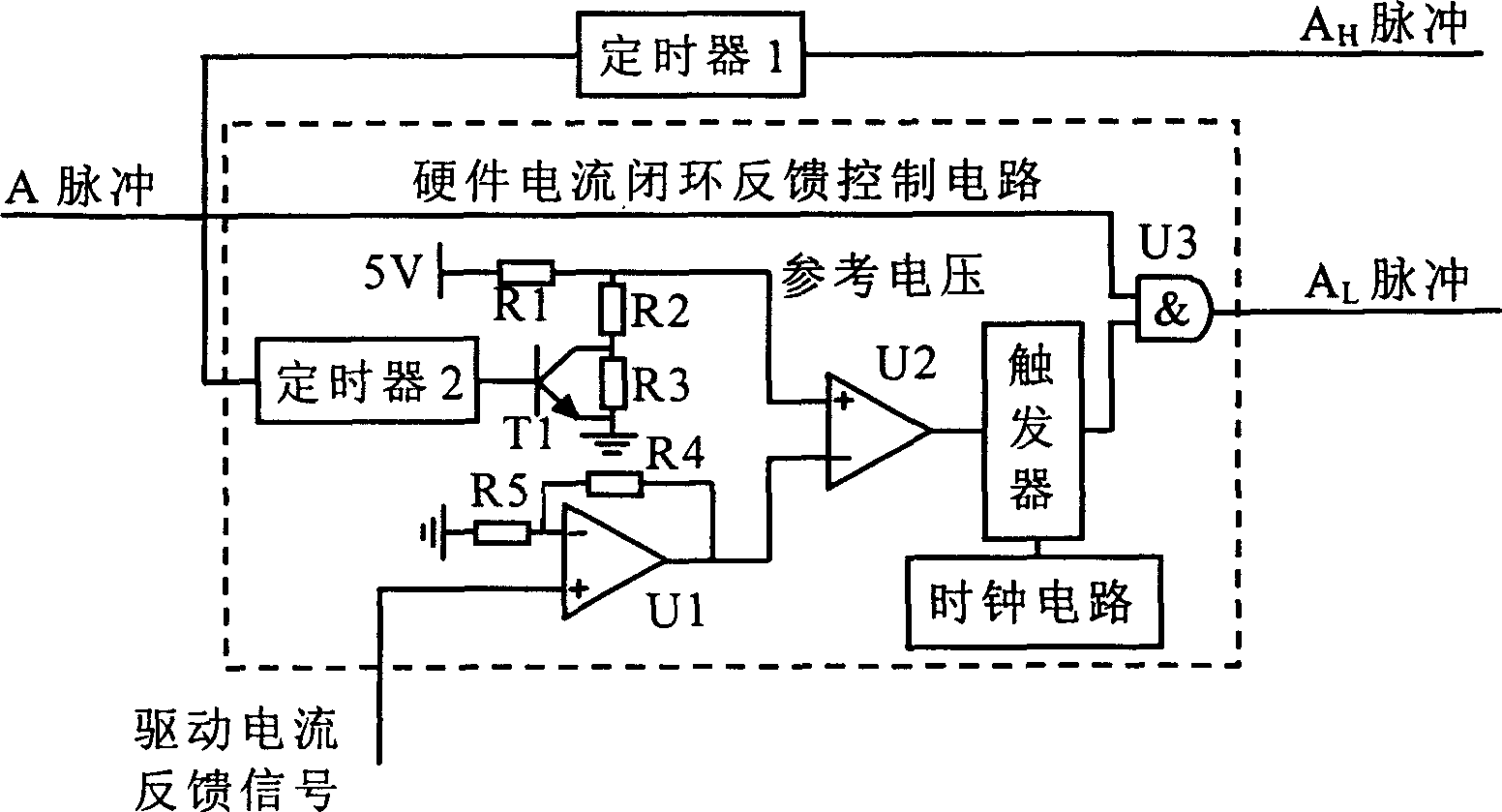

[0015] See figure 1 , the present invention mainly includes three parts: a high-end drive circuit, a low-end drive circuit and a signal processing circuit. Taking driving a six-way solenoid valve as an example, the high-end drive circuit is located in the solenoid valve L 1 -L 6 (L 2 -L 5 Not marked in the figure) one end, including two sets of independent drive power and power transistors, one set includes high-voltage drive power U H and high voltage power transistor M H (Model is IRFB61N15D), among them, the high-voltage driving power supply voltage is 100V±50V, generally 100V is desirable, and the high-voltage power transistor M H A output by the signal processing circuit H Pulse signal control. The other set includes low voltage drive power supply U L and low voltage power transistor M L (Model

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap