Dual-bottle type water heater

A technology of water heater and double inner tank, applied in the directions of water heater, fluid heater, lighting and heating equipment, etc., can solve the problems of energy waste, inability to obtain hot water, influence of bathing comfort, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

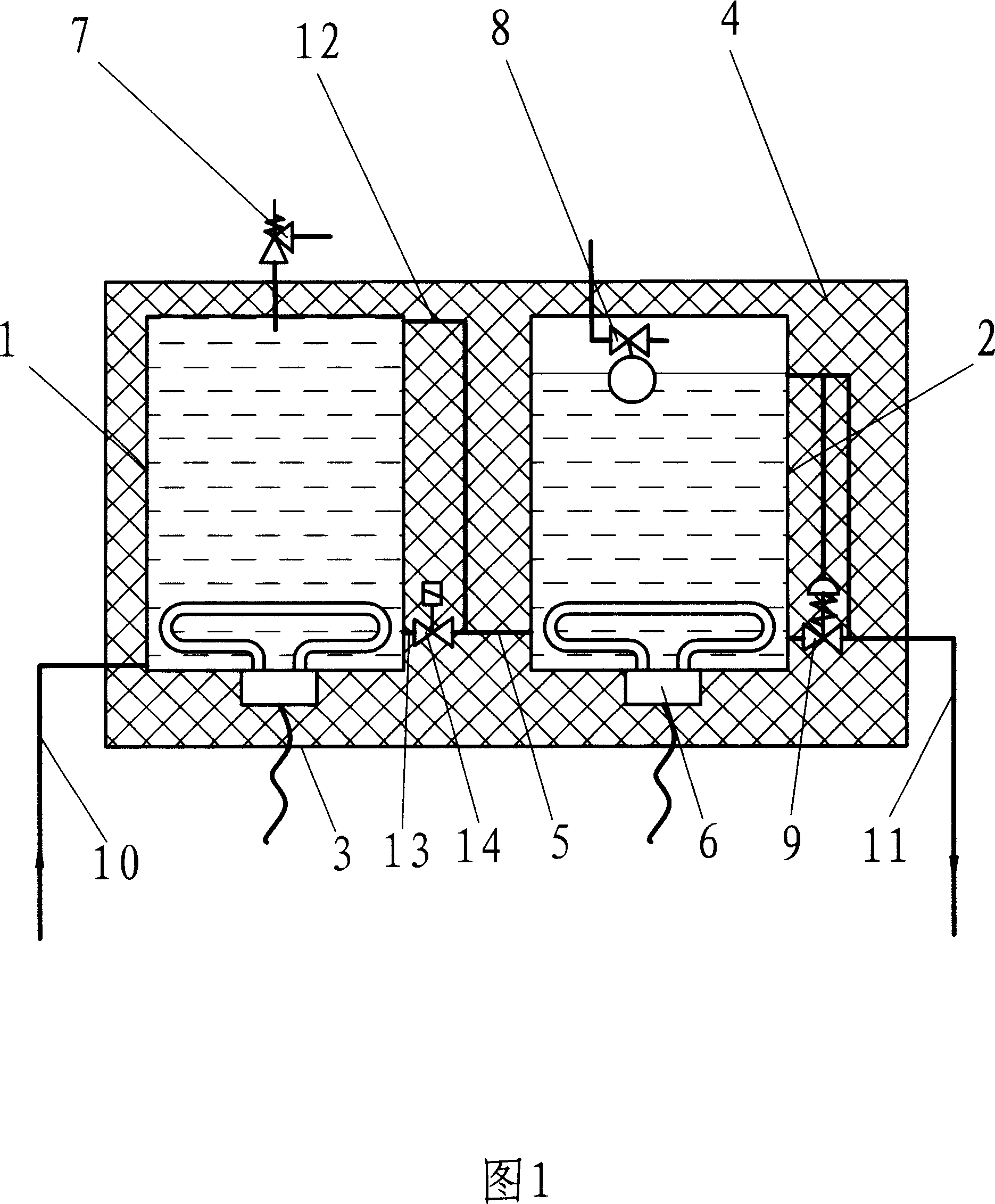

[0009] The specific embodiment shown in Figure 1 is a dual-inner electric water heater for heating by electric energy, which mainly consists of a water inlet inner tank 1, a water outlet inner tank 2, a shell 3, an insulating material 4, a connecting pipe 5, and an electric heater. 6. Safety valve 7, float valve 8, hydraulic control valve 9, upper water pipe 10, lower water pipe 11, upper water outlet pipe 12, lower water outlet pipe 13, water inlet liner 1 and water outlet liner 2 are installed in the shell 3 , between the water inlet inner tank 1 and the water outlet inner tank 2, between the two inner tanks and the outer shell 3 is filled with thermal insulation material 4, the lower parts of the two inner tanks are equipped with electric heaters 6, and the lower part of the water inlet inner tank 1 is fixedly connected The upper water pipe 10, the safety valve 7 and the floating ball valve 8 which plays the role of degassing are respectively installed on the outside and inside

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap