Control device for motor-driven 4WD vehicle and related method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0016] First, description is made of a first embodiment according to the present invention.

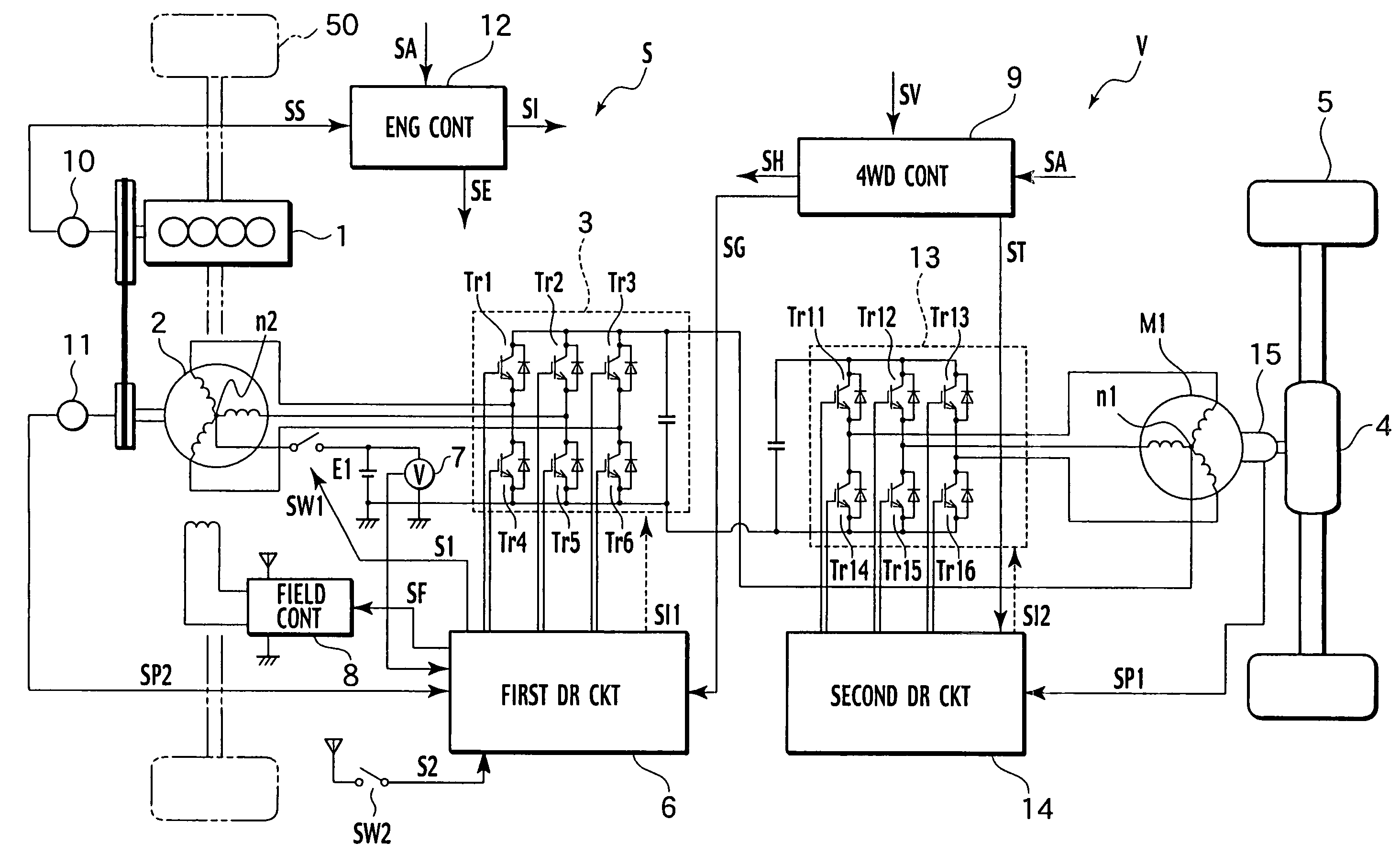

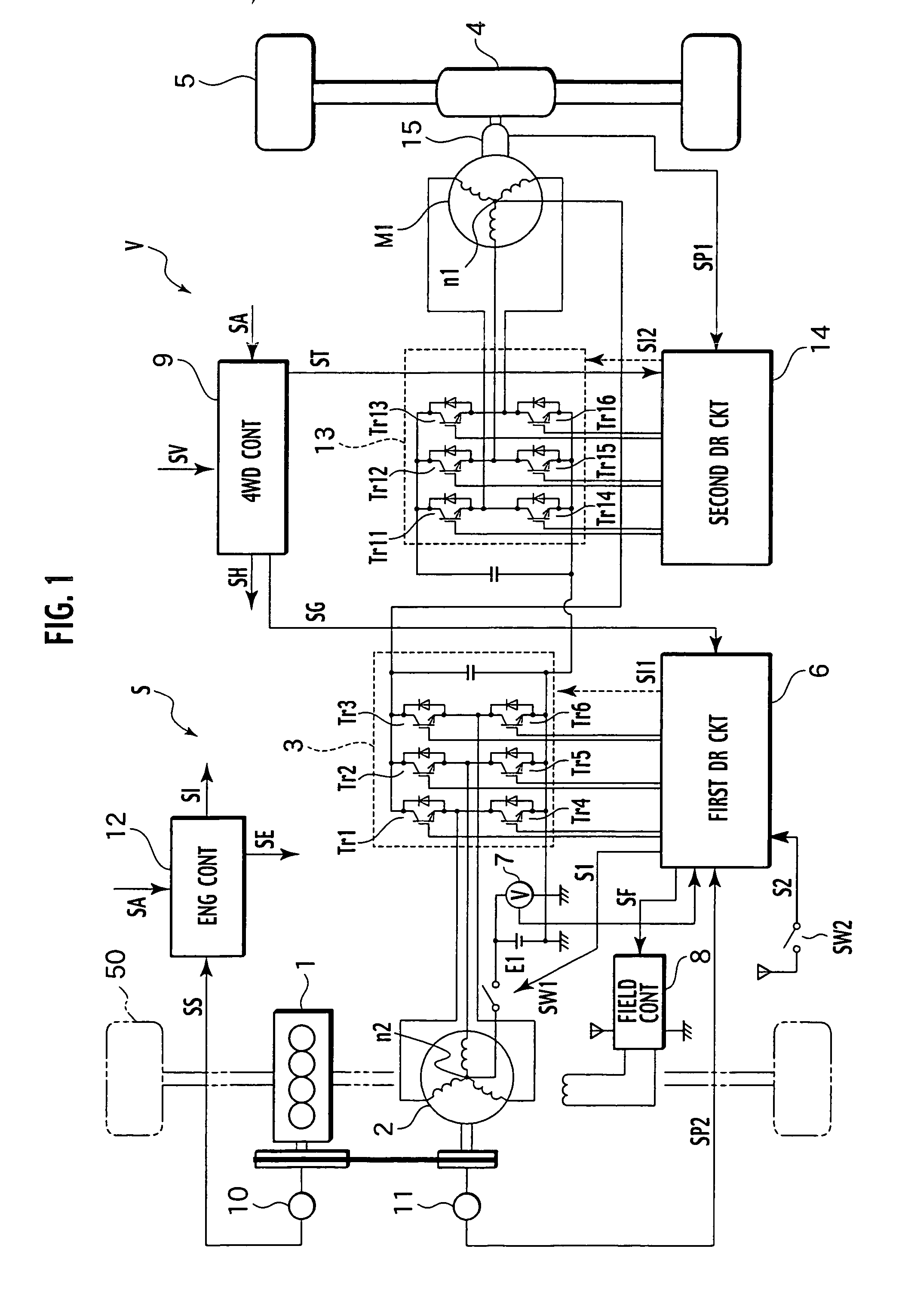

[0017]FIG. 1 is a block diagram showing a structure of a control device S of a motor-driven 4WD vehicle of the presently filed embodiment.

[0018] The control device S of the presently filed embodiment may be sufficed to be of a type that controls a vehicle V with a structure wherein in principle, either of front wheels 50 and rear wheels 5 are driven by an engine and the others are driven by a motor.

[0019] Typically, as shown in FIG. 1, the vehicle V is comprised of an engine 1, an alternator 2 (a 42V alternator: electric power generator) driven by rotational power of the engine 1 to generate three-phase AC power (first three-phase AC power: approximate maximum power of 4 kW and voltage within a range of 11 to 42 Vrms), a battery E1 (a 14V battery) that supplies electric power to a variety of instrumented equipments installed on the vehicle, and a three-phase AC motor M1 for driving rear wheels

second embodiment

[0066] Next, description is made of a second embodiment according to the present invention.

[0067]FIG. 6 is a block diagram illustrating a structure a control device S′ of a motor-driven 4WD vehicle of the presently filed embodiment.

[0068] As shown in FIG. 6, like in the first embodiment, the control device S′ of the presently filed embodiment is comprised of the engine 1, the 42V alternator 2, the three-phase AC motor M1, the engine speed sensor 10, the rear set-up and set-down inverter (the first set-up and set-down inverter) 13 and the 4WD controller 9 but principally differs from the first embodiment in the absence of the front set-up and set-down inverter (the second set-up and set-down inverter) 3.

[0069] Additionally, the control device S′ of the presently filed embodiment further includes a diode bridge circuit 23, which rectifies three-phase AC power generated by the 42V alternator 2, whose output terminals have a positive terminal that is connected to a neutral point n1 of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap