Apparatus and method for improving electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

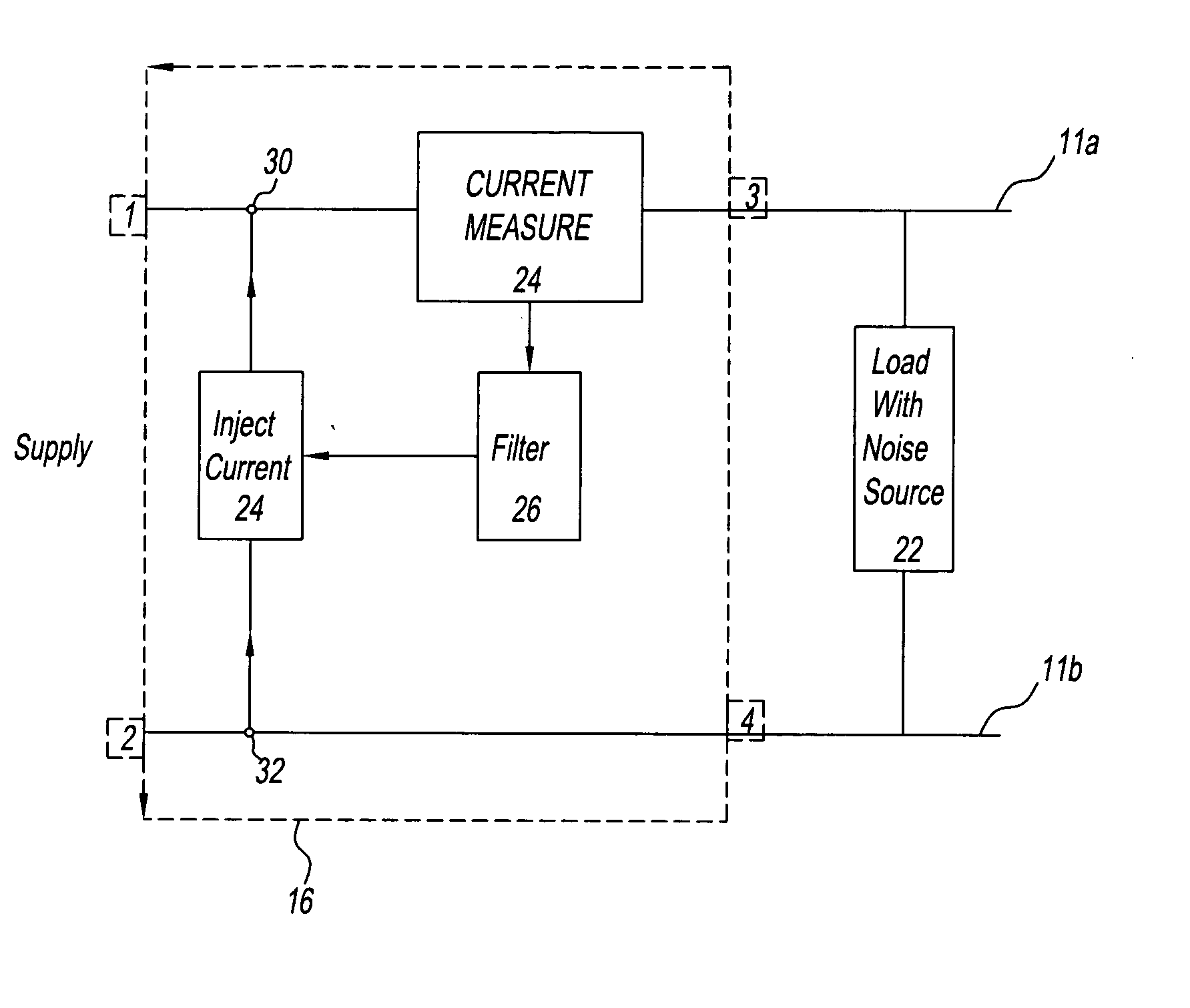

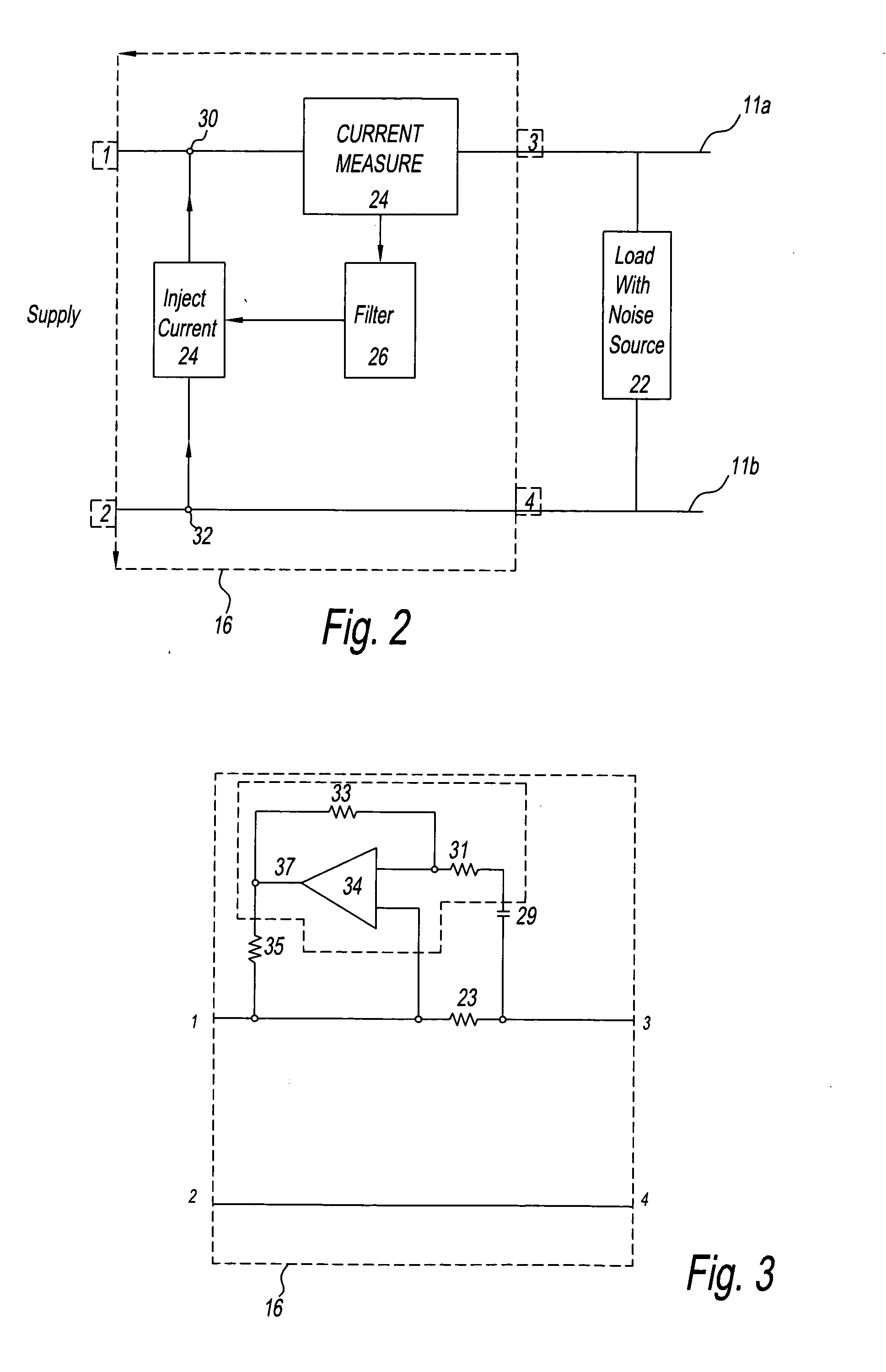

[0033]FIG. 2 shows a schematic block diagram of a first embodiment of the EMC filter 16 of the present invention. This embodiment utilises open loop filtering to try to achieve noise cancellation. The filter 16 of this embodiment is inserted into the apparatus of FIG. 1 as described above. A noise source 22 is shown in FIG. 2 and represents the switching element 19, capacitor 17 and inductors 13 and 15 of FIG. 1, which may generate noise on the first and second power rails 11a, 11b. A measurement device 24 is coupled in series on the first power rail 11a between input 1 and output 3 to monitor the current on the first power rail 11a and produce a measurement parameter proportional to the current flowing on the first power rail 11a. The measurement device 24 has an output coupled to a filter 26, the measurement parameter being passed to the filter 26, where any DC element is substantially blocked from passing through. The filter 26 may also filter the measurement parameter to a level wh

Example

[0040]FIG. 4 shows a schematic block diagram of a second embodiment of an EMC filter 116 according to the present invention. This second embodiment utilises closed loop filtering to achieving noise cancellation. Once again, the circuitry forming the EMC filter 116 is inserted into the apparatus 10 of FIG. 1 as described above. Again, a noise source 122 is shown in FIG. 4 and represents the switching element 19, capacitor 17 and inductors 13 and 15 of FIG. 1, which may generate noise on the first and second power rails 11a, 11b. A measurement device 124, coupled in series on the first power rail 111a between input 1 and output 3, monitors the current on the first power rail 111a and produces a measurement parameter proportional to the current flowing on the first power rail 111a. The measurement device 124 has an output coupled to a filter 126, which substantially blocks any DC element passing through. The filter 126 also filters and / or amplifies the measurement parameter to a level w

Example

[0044]FIG. 6 shows a schematic block diagram of a third embodiment of an EMC filter 216. This third embodiment again utilises closed loop filtering to achieving noise cancellation, although it may be worked in an open loop configuration similar to that of the first embodiment of FIGS. 2 and 3. Again, the circuitry forming the EMC filter 216 is inserted into the apparatus 10 of FIG. 1 as described above. The noise source 222 created by the switching element 19, capacitor 17 and inductors 13 and 15 of FIG. 1 generates noise on the first and second power rails 211a, 211b. A measurement device 224 coupled in parallel between the first power rail 211a and the second power rail 211b monitors the voltage between the first power rail 211a and the second power rail 211b and produces a measurement parameter proportional to that measured voltage. The measurement device 224 has an output coupled to a filter 226, which substantially blocks any DC element passing through. The filter 226 also filters

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap