Remotely communicating, battery-powered nanostructure sensor devices

a nanostructure sensor and remote communication technology, applied in the direction of electric signalling details, fire alarms, instruments, etc., can solve the problems of large amount of power, and relatively small amount of power, and achieve the effect of increasing range and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

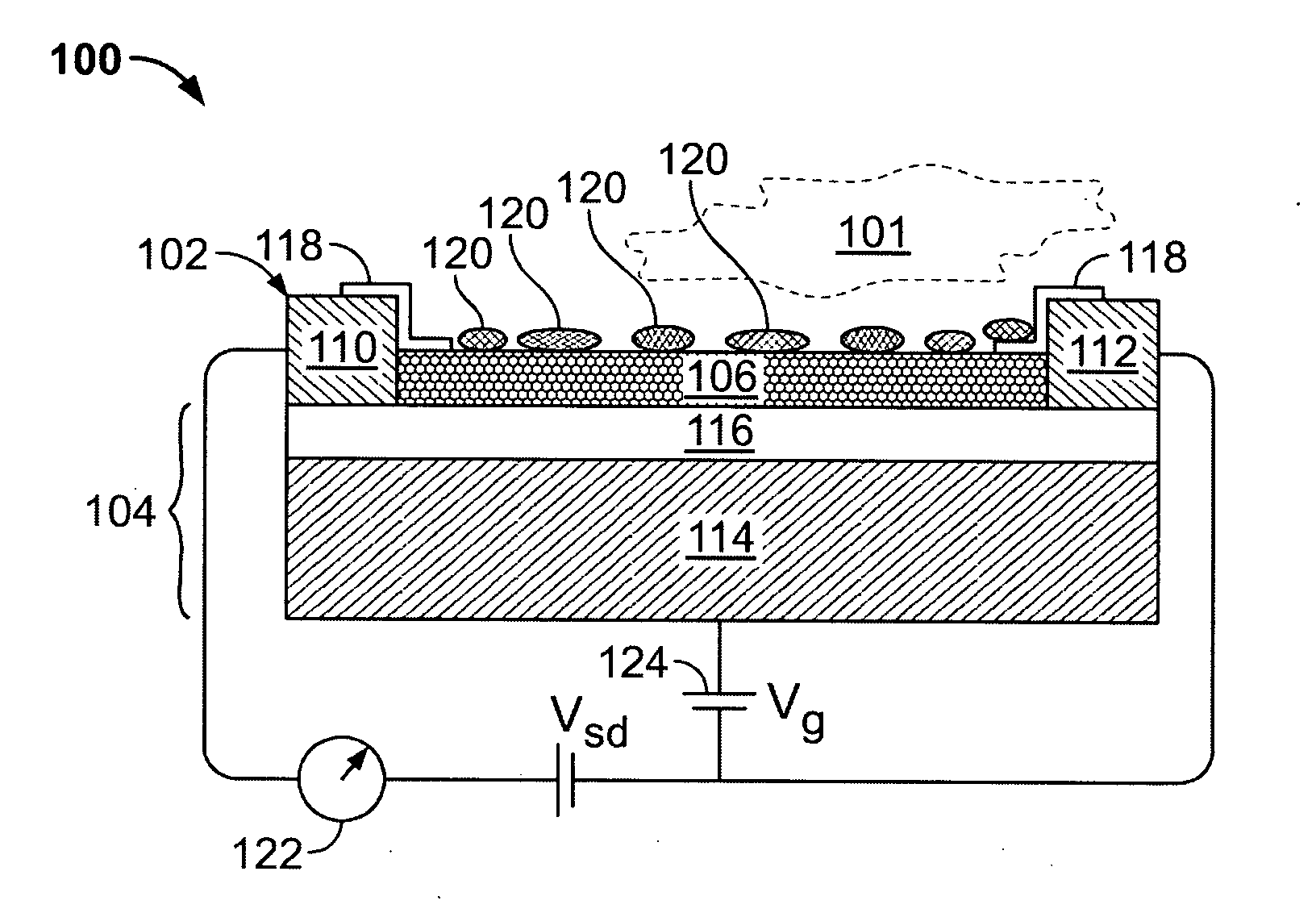

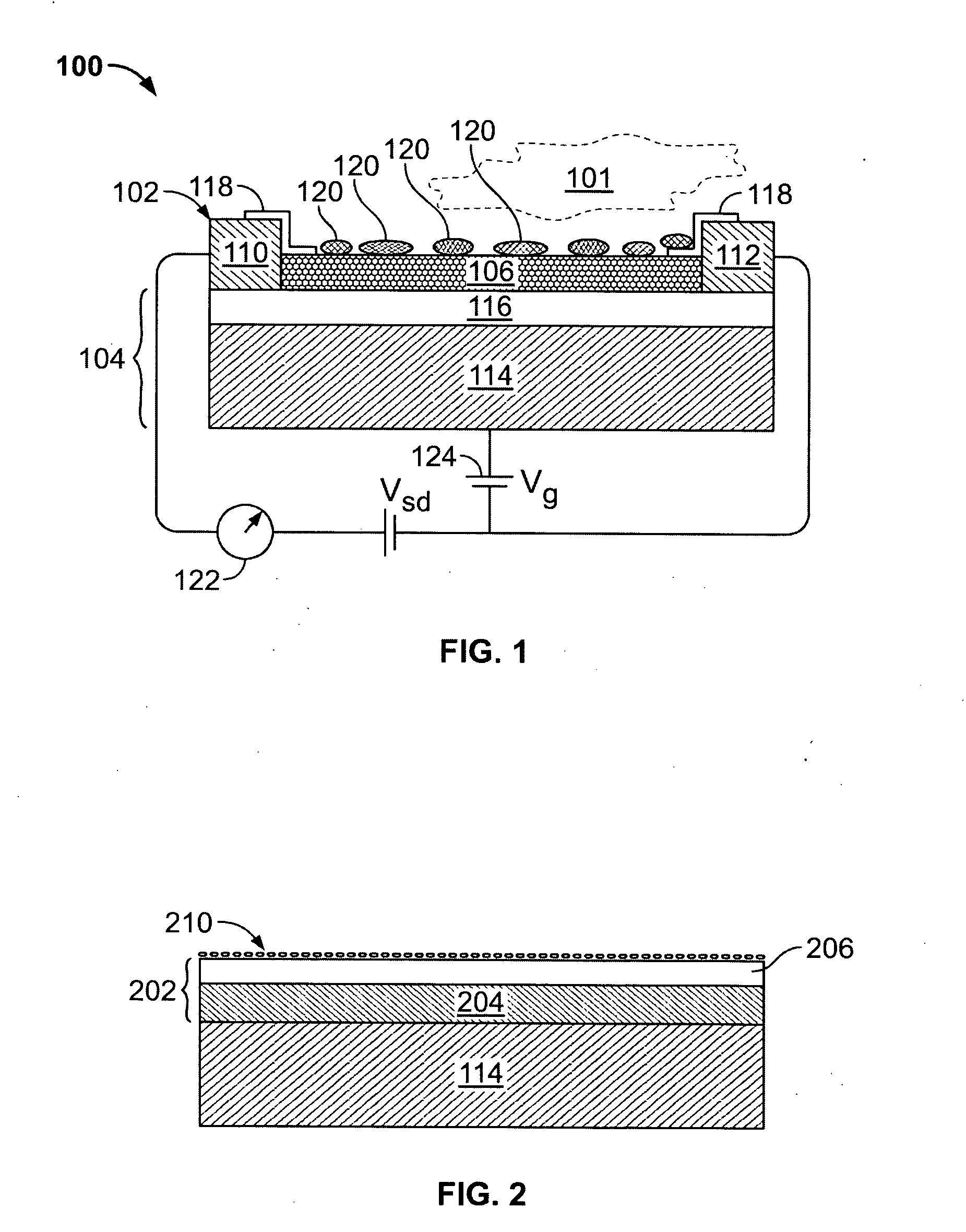

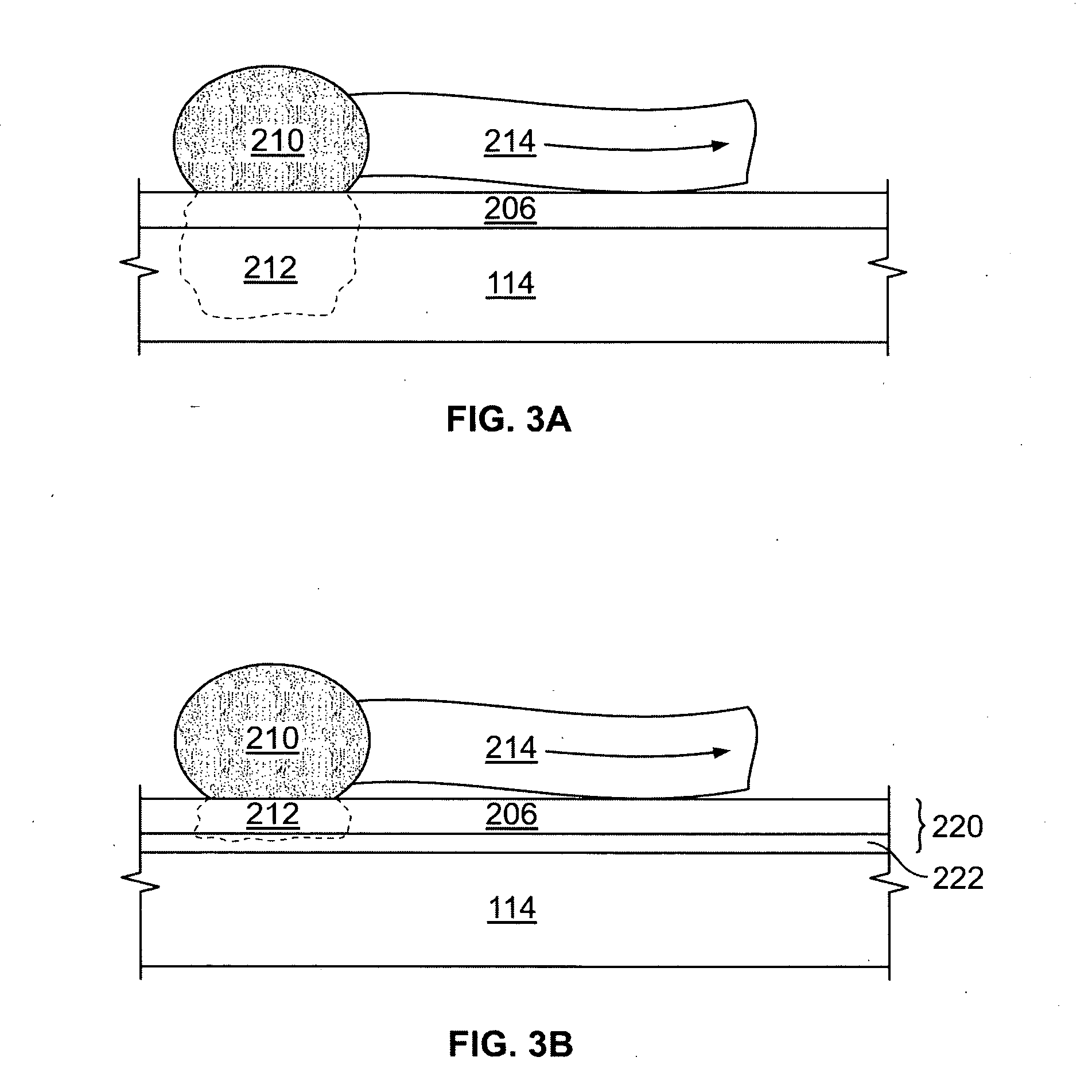

Method used

Image

Examples

example a

[0118] Nanotube Network CO2 Sensor with remote measurement circuitry. An exemplary NTFET H2 sensor with remote measurement circuitry was prepared as follows. A degenerately doped silicon wafer with a silicon oxide film was coated with carbon nanotubes in a random network, as described in the above-incorporated application Ser. No. 10 / 177,929. A plurality of nanosensor devices 500 were thus formed, one of which is shown schematically in FIG. 5. Titanium contacts 35 nm thick covered with gold contacts 100 nm thick were deposited and patterned by photolithography and lift-off to form opposing contacts 502, 504. Contacts 502, 504 each comprised a plurality of interdigitated portions disposed over a generally rectangular region 506. A network of randomly oriented nanotubes 508 was disposed over the silicon substrate in electrical contact with interdigitated portions of contacts 502, 504.

[0119] After the deposition of the contacts 502, 504 and network 508, nanotubes outside of the general

example b

[0125] Nanotube Network H2 Sensor with remote measurement circuitry. The process as described above in Example A, except for deposition of polyethylene imine, was carried out construct a bare (non-functionalized) nanosensor device. Over a range of gate voltages between +10 V and −10 V, the maximum conductance of the bare device was approximately 10 kΩ, and the on-off ratio was approximately 10. Many such devices were constructed on individual dies of a wafer. To functionalize for hydrogen, palladium metal was deposited on the substrate and patterned using photolithography and lift-off, as described above.

[0126] A selected die was separated from the wafer and mounted in a standard 16-pin chip carrier. Wires were used to connect leads 510, 512 to the contacts on the chip carrier, which connected to measurement circuitry on a prototype circuit board. The measurement circuit 600 was constructed as diagrammed in FIG. 7, using integrated circuit chips mounted on the same circuit board as th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap