Pneumatic tire with tread siping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The following language is of the best presently contemplated mode or modes of carrying out the invention. This description is made for the purpose of illustrating the general principles of the invention and should not be taken in a limiting sense. The scope of the invention is best determined by reference to the appended claims.

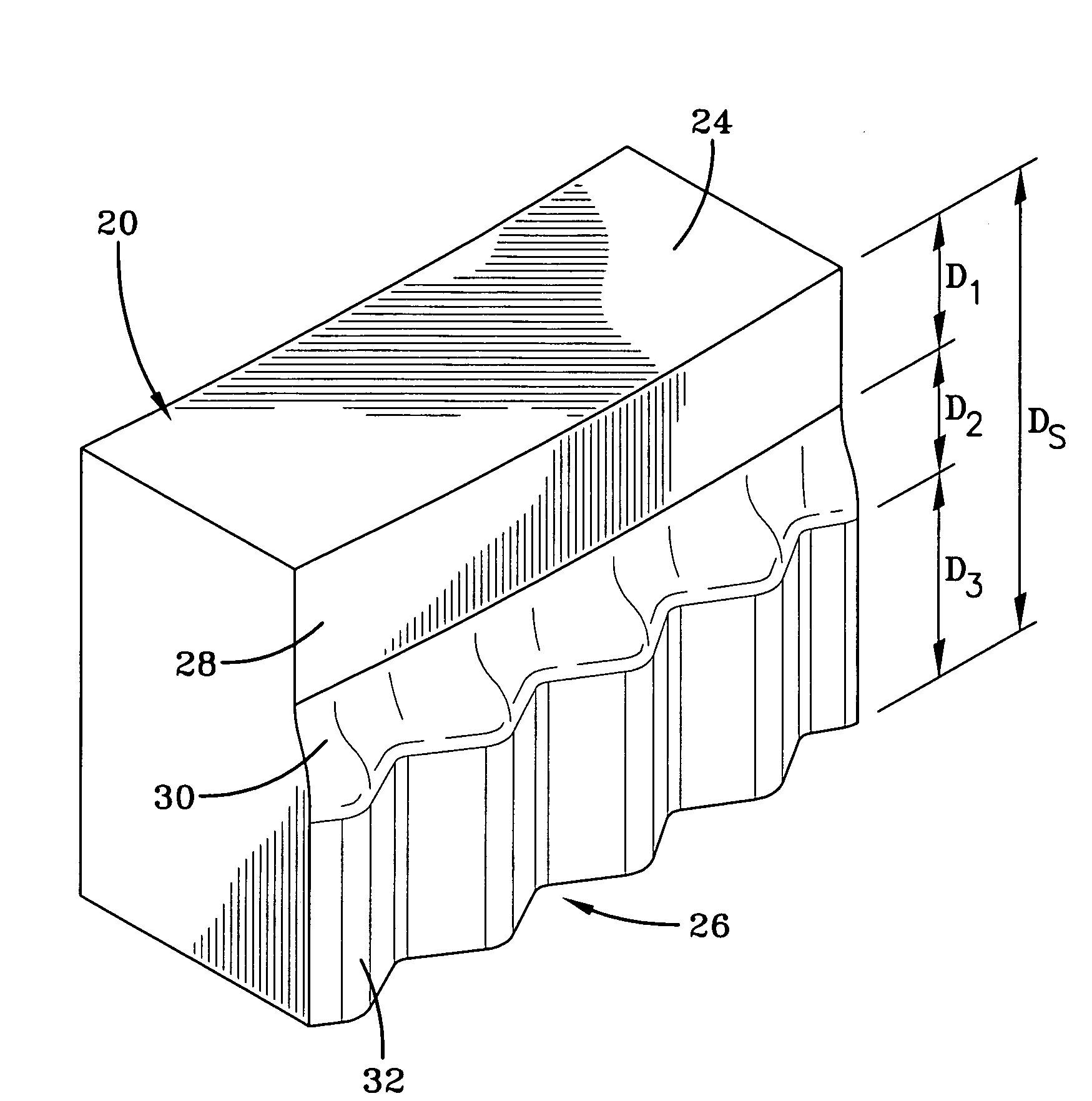

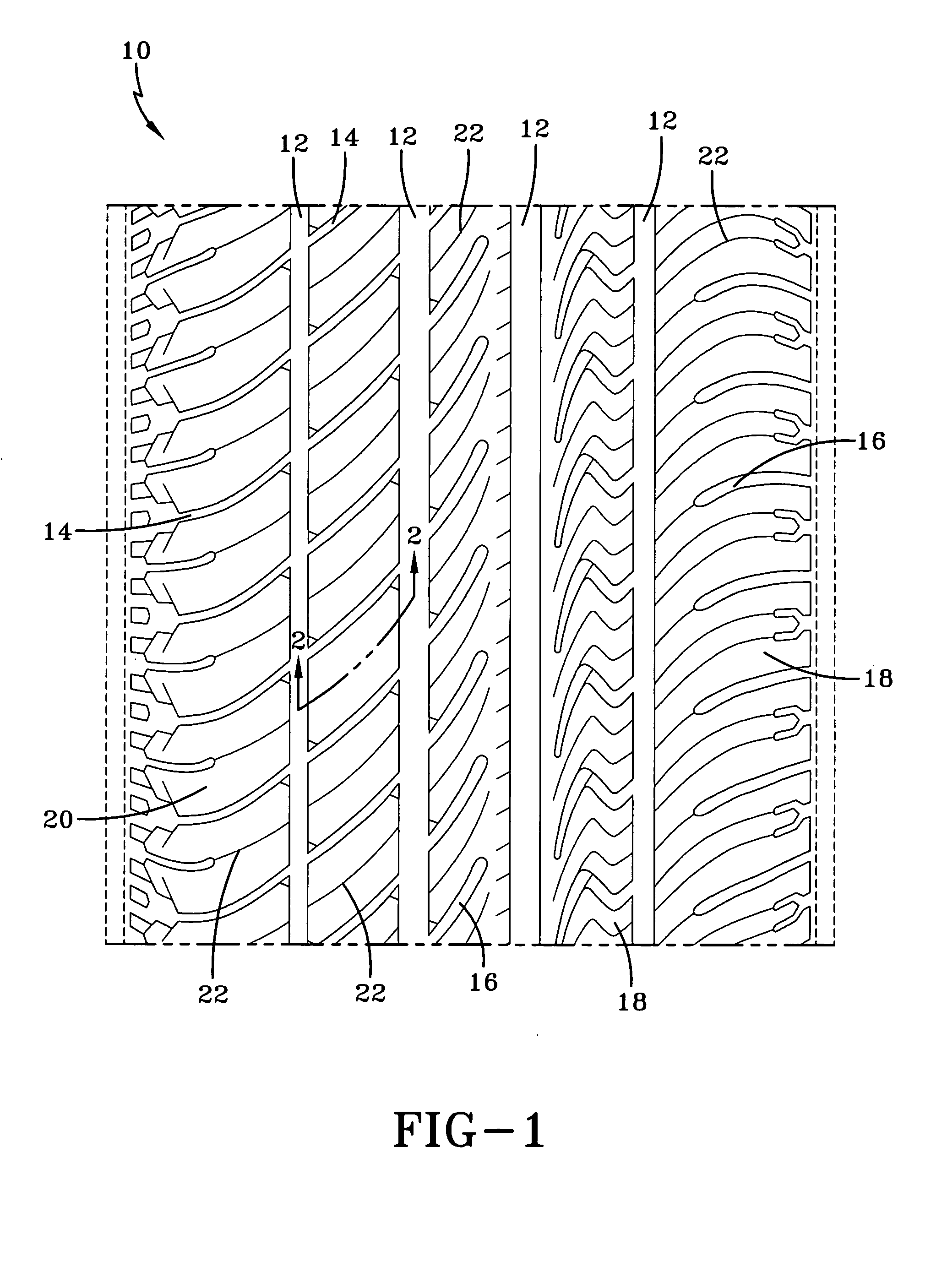

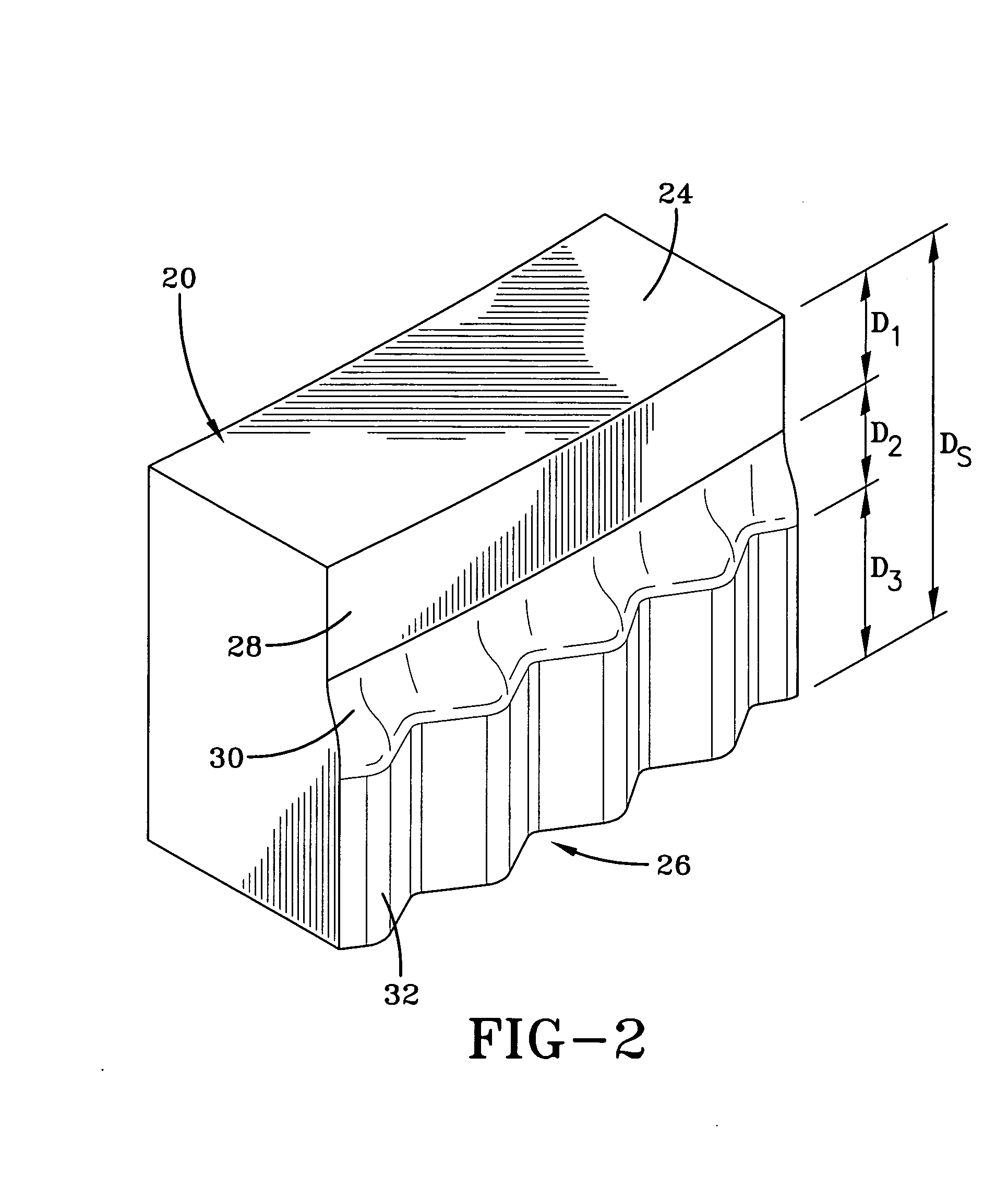

[0028]FIG. 1 is an exemplary tread 10 for a pneumatic tire. The tire employing the illustrated tread may be of a radial or bias construction; the more typical being a radial construction. The tire tread 10 has a plurality of circumferential grooves 12 and a plurality of lateral grooves 14, 16. These grooves 12, 14, 16, in different combinations from a plurality of tread elements 18, 20. Some of the lateral grooves 14 extend between the circumferential grooves 12 and some terminate within the tread element 20, creating a blind groove 16. For the illustrated tread, within each tread element 18, 20, the tread element being either a block, such as tread elemen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap