Thrust washer for universal joint cross

a technology of universal joint and washer, which is applied in the direction of sliding contact bearings, couplings, mechanical equipment, etc., can solve the problems of premature wear and generation of undesirable noise and vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

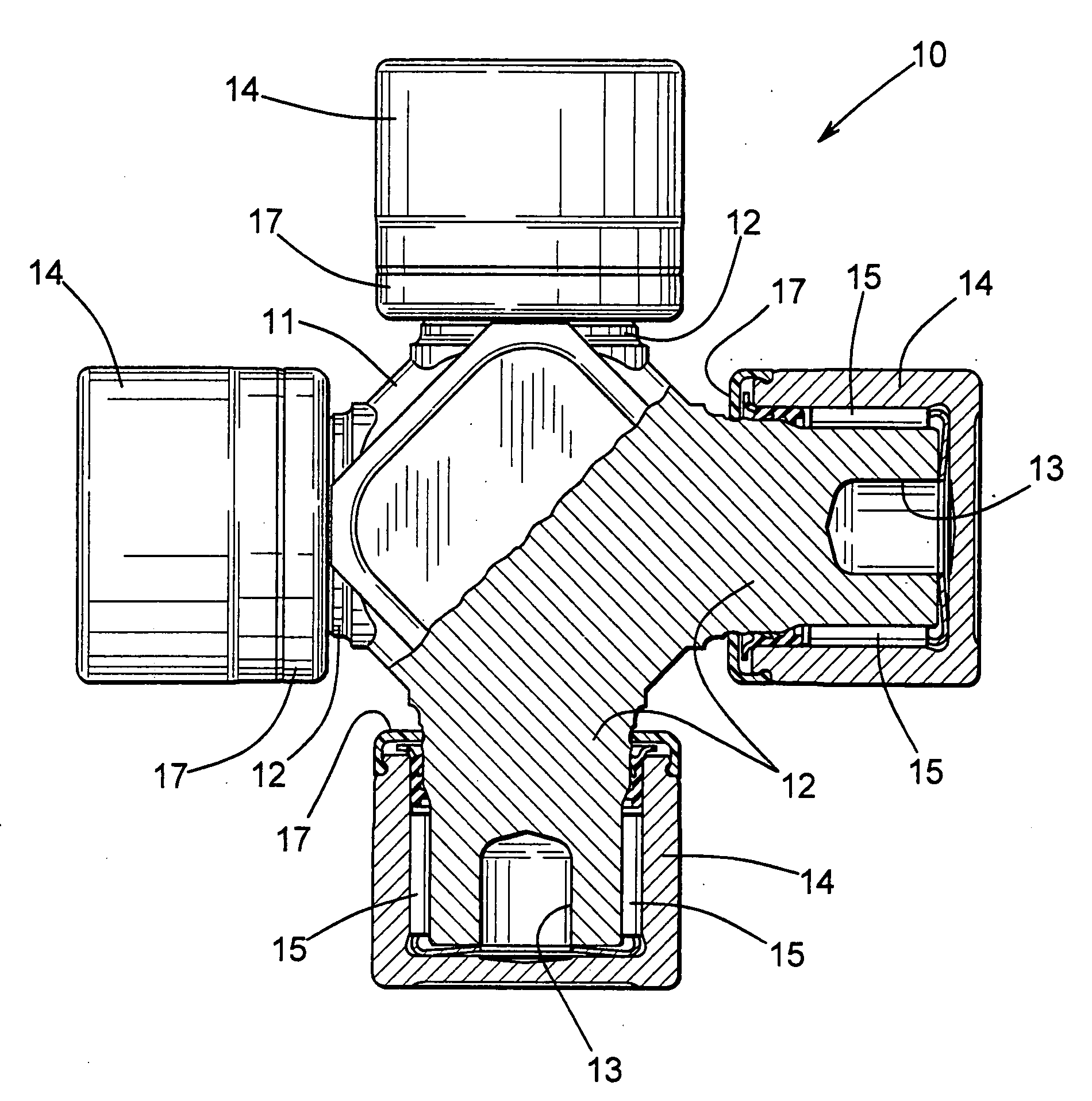

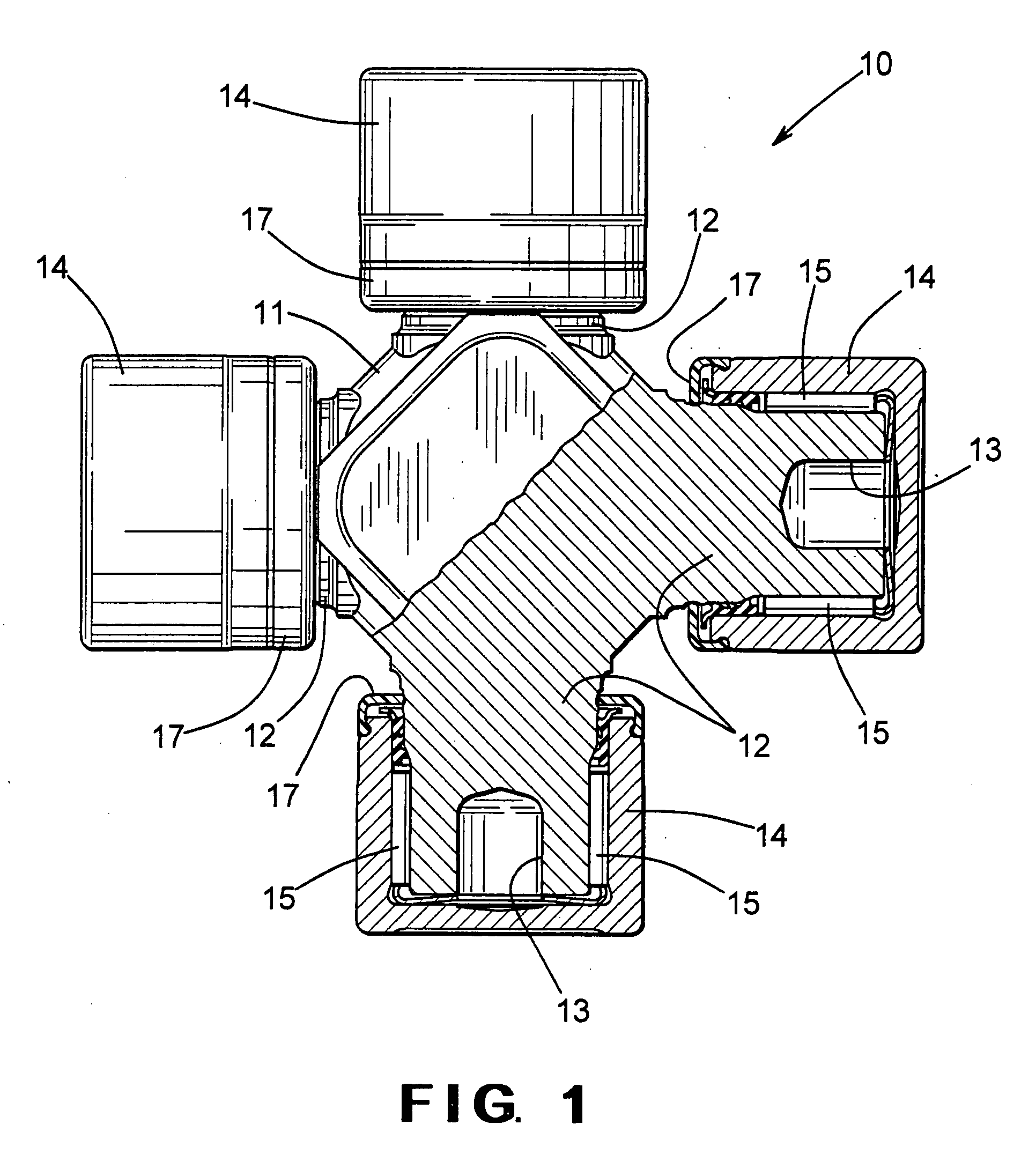

[0023]Referring now to the drawings, there is illustrated in FIG. 1 a cross, indicated generally at 10, in accordance with this invention. The cross 10 is adapted to form a portion of a universal joint (not shown), such as described above and conventionally used in drive train system. The illustrated cross 10 includes a central body 11 having a plurality of trunnions 12 extending outwardly from the body 11. In the illustrated embodiment, four of such trunnions 12 are formed integrally with the body 11. The illustrated trunnions 12 are disposed at right angles relative to one another and are oriented so as to lie in a single plane, although such is not required. The illustrated trunnions 12 are generally cylindrical in shape and define respective axes of rotation, although again such is not required.

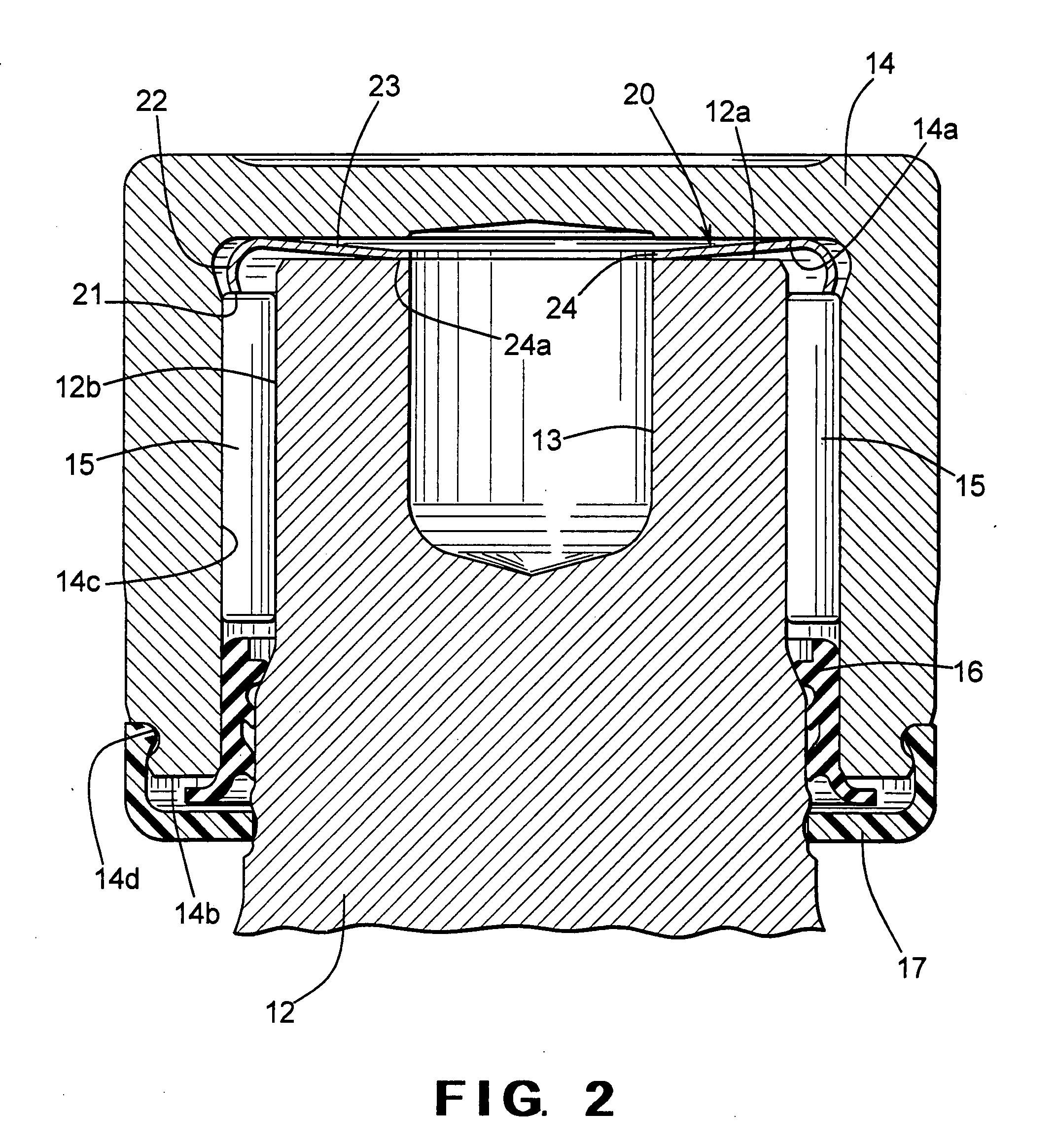

[0024]As best shown in FIG. 2, each of the illustrated trunnions 12 is generally cylindrical in shape, having an outer end surface 12a and an outer cylindrical surface 12b. However, the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap