Coil device and method for manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

EXPLANATION OF REFERENCE NUMERALS

[0049]1 core

[0050]11 rib

[0051]2 coil

[0052]21 conductive wire

[0053]22 winding portion

[0054]3 twist part

[0055]4 lead part

[0056]5 lead part

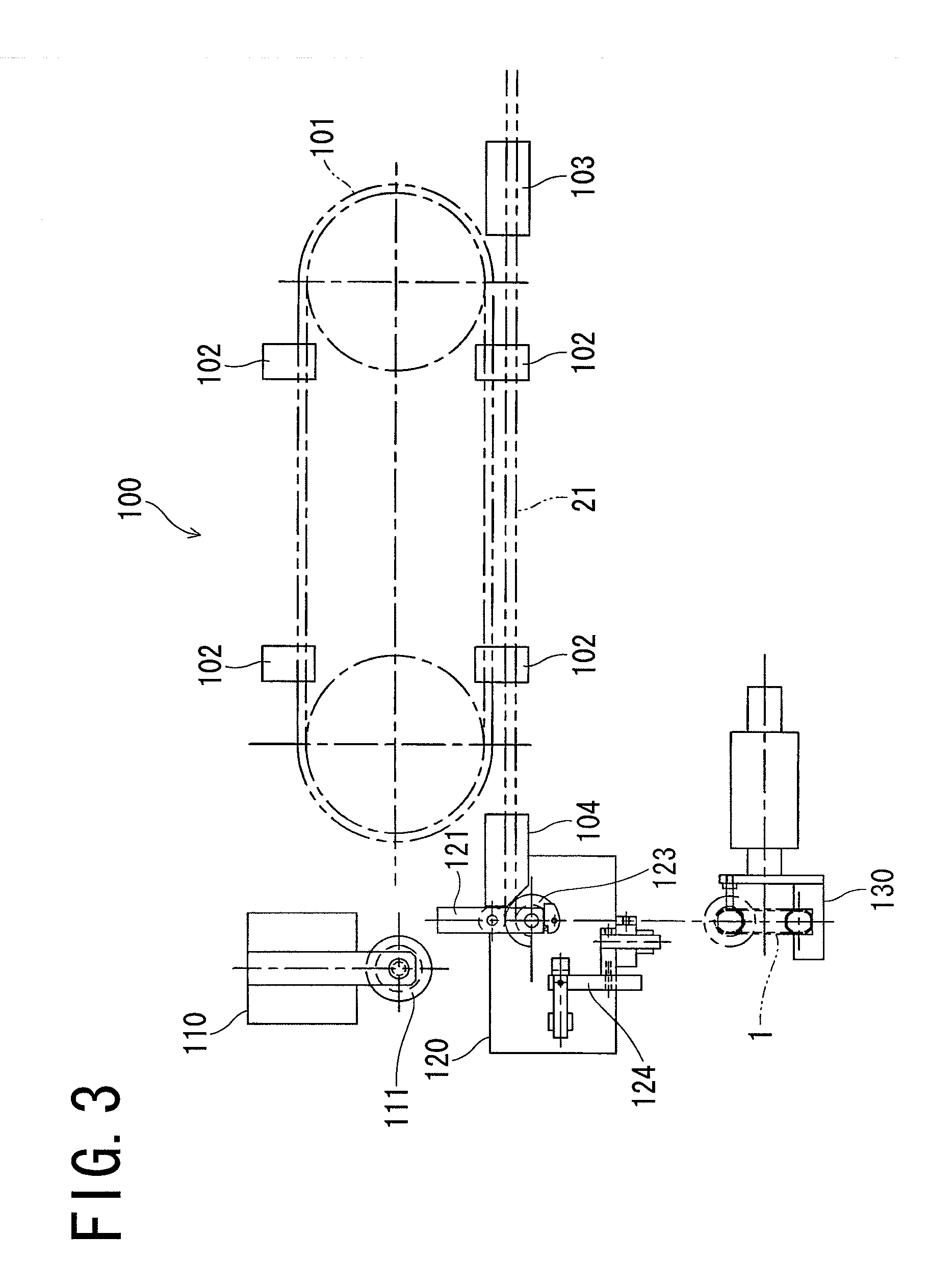

[0057]100 conductive wire feeding device

[0058]110 forming device

[0059]120 tip end part forming device

[0060]130 core holding device

[0061]140 conductive wire folding mechanism

BEST MODE FOR CARRYING OUT THE INVENTION

[0062]An embodiment of the present invention is to be described in detail below with reference to the drawings.

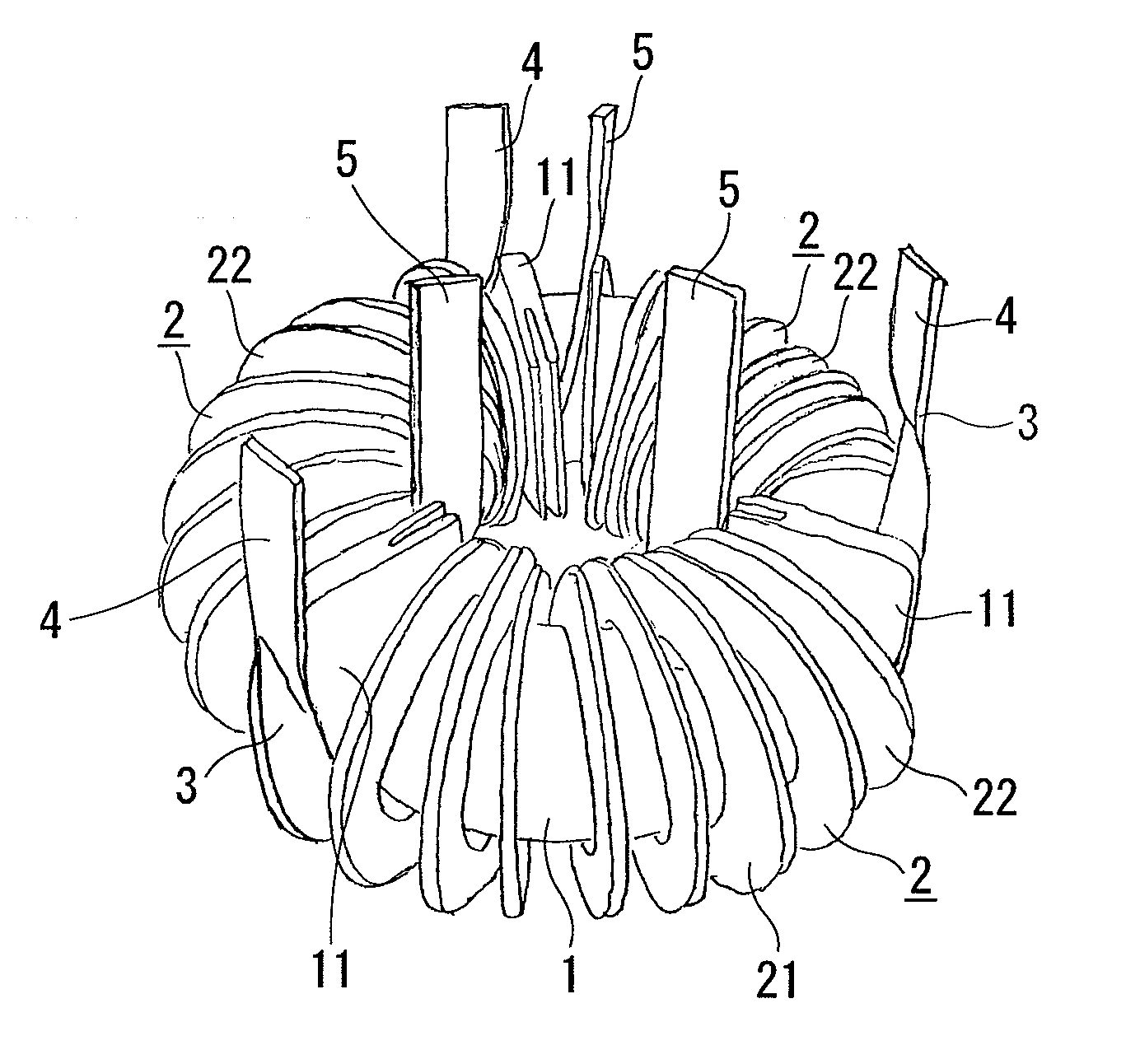

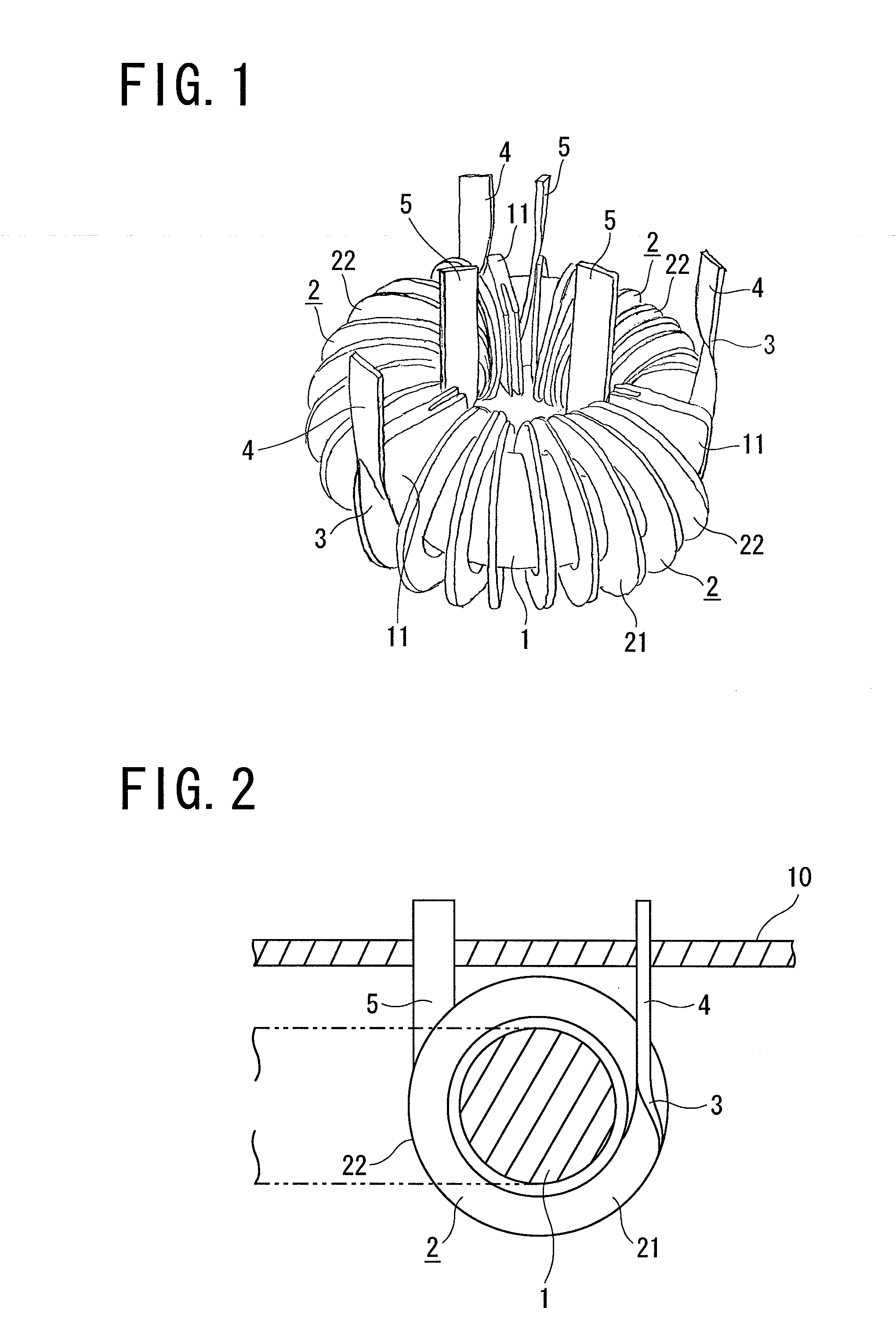

[0063]A coil device according to the present invention comprises a ring-like core 1 and three coils 2, 2, 2 wound around the core 1 as shown in FIG. 1. A three-phase alternating current is supplied to the three coils 2, 2, 2.

[0064]Specifically, the core 1 comprises a ring-like magnetic core covered by a covering layer made of synthetic resin, and three ribs 11, 11, 11 project with a phase difference of 120 degrees on an outer peripheral surface of the core 1. Three winding areas are thereby formed, and

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap