Automatic amplitude control for voltage controlled oscillator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

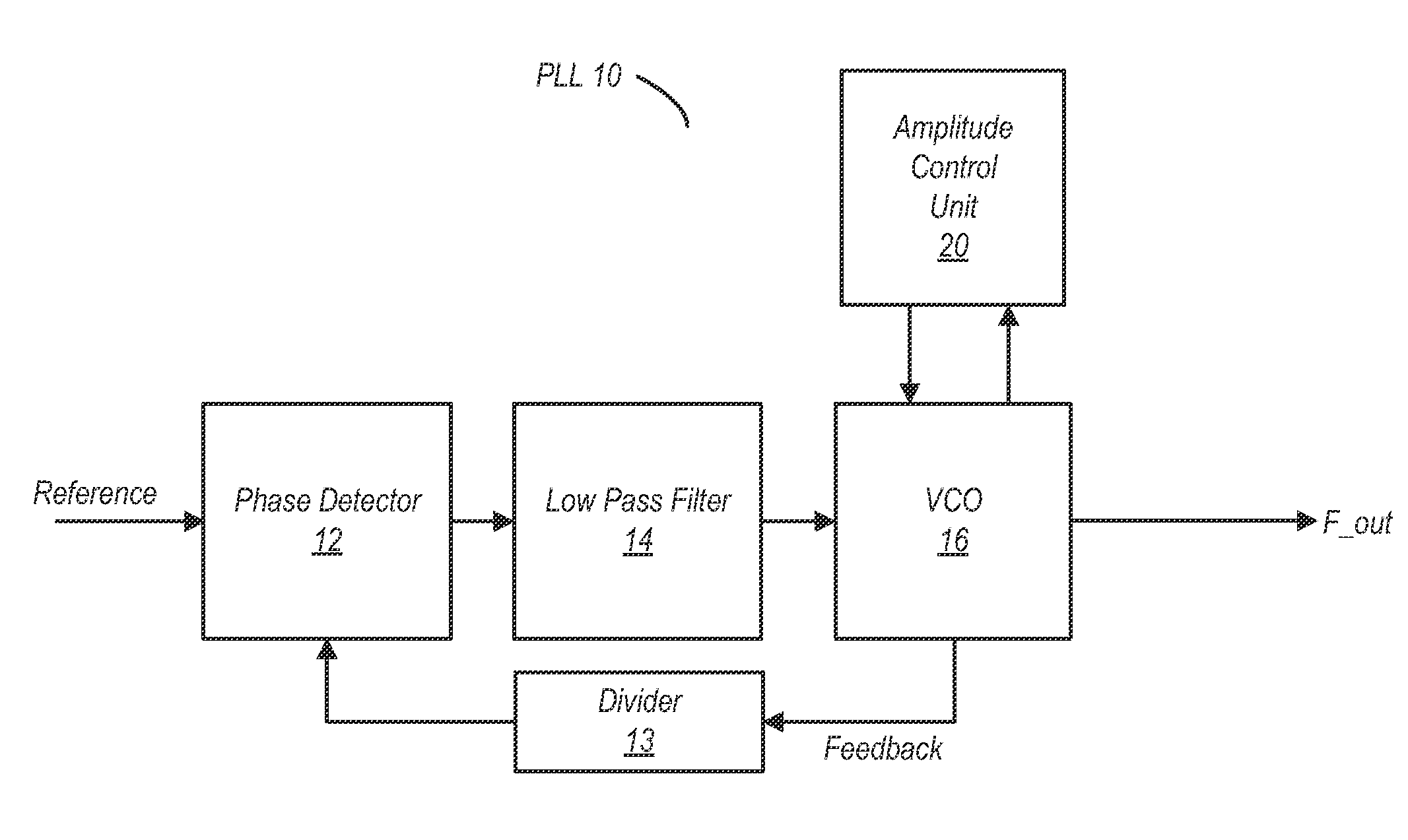

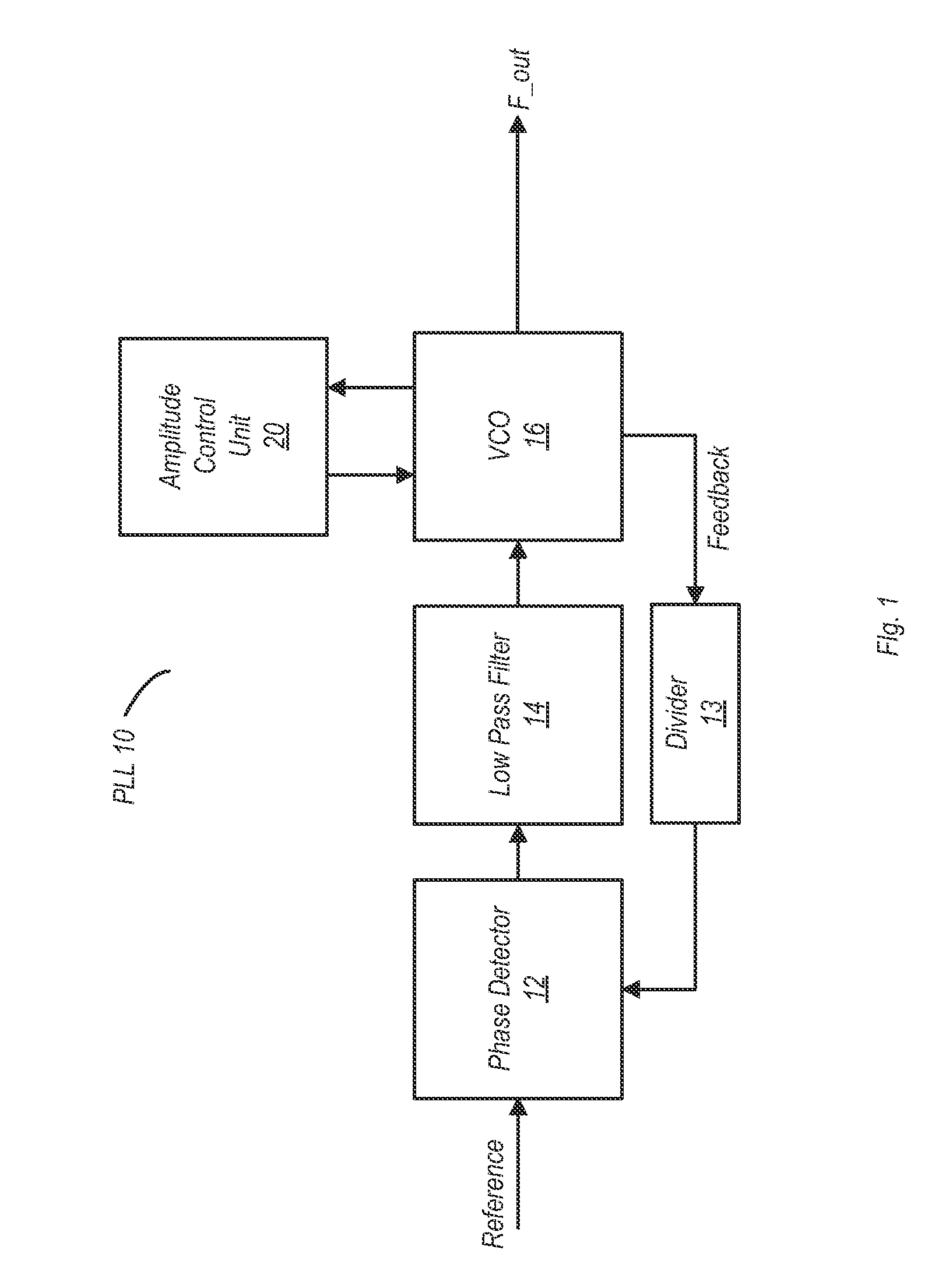

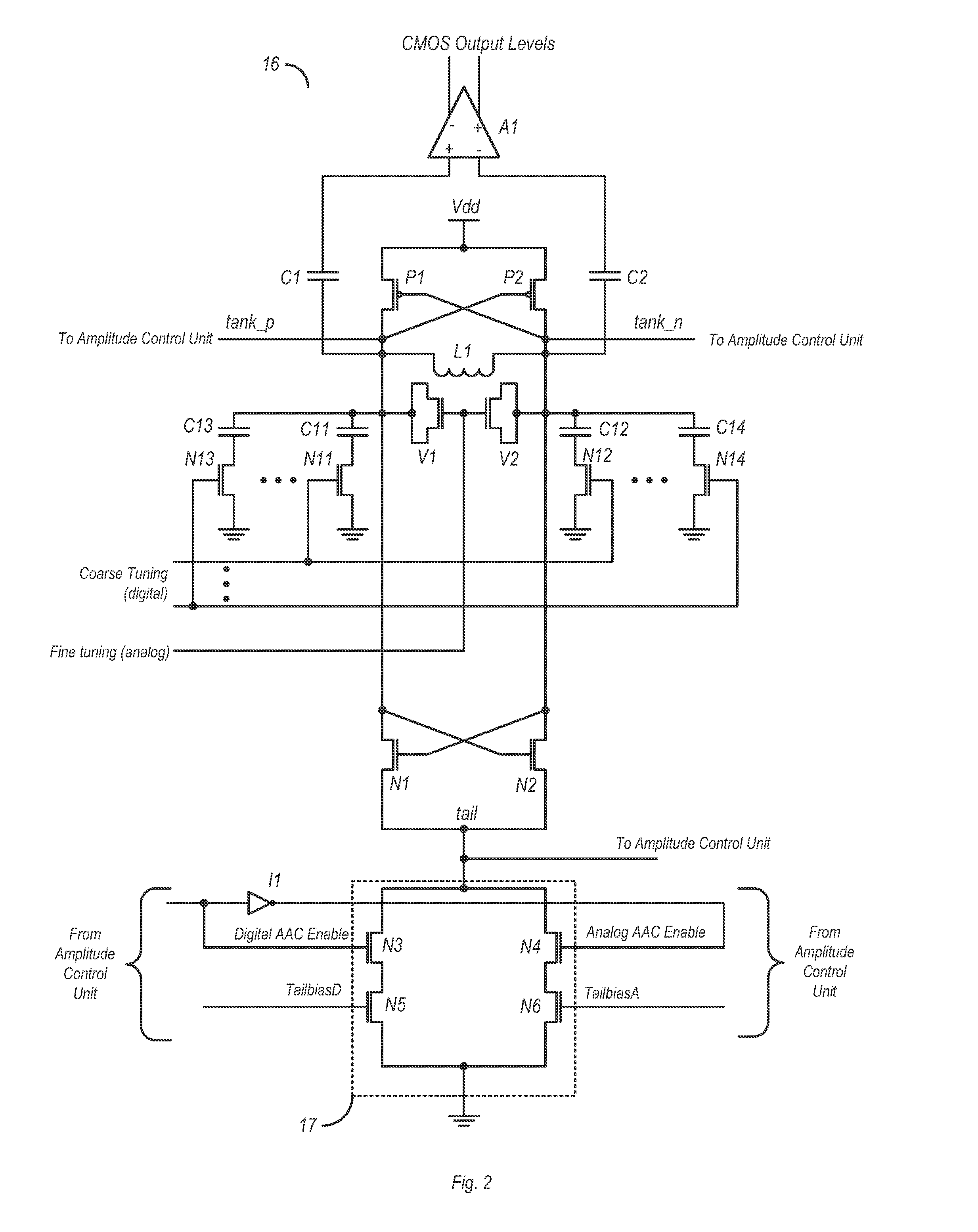

A method and apparatus for calibrating the amplitude of an output signal of a voltage-controlled oscillator (VCO) is described below by way of the examples in the drawings. The VCO may include an LC (inductive-capacitive) tank circuit. Monitoring of the output signal may be performed non-invasively by monitoring a tail node of the VCO instead of through a direct coupling to the LC tank circuit. By non-invasively monitoring the amplitude of the VCO output signal, problems such as loading (which can reduce the turning range of the LC tank circuit) may be avoided.

An amplitude control unit configured to calibrate the amplitude of the VCO output signal may determine its amplitude based on the voltage present on the tail node. Based on the tail node voltage and a target voltage, the amplitude control unit may determine whether or not the amplitude of the VCO output signal is within a specified range (e.g., if the tail node voltage exceeds the target voltage). If the amplitude is not within t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap