Connector assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

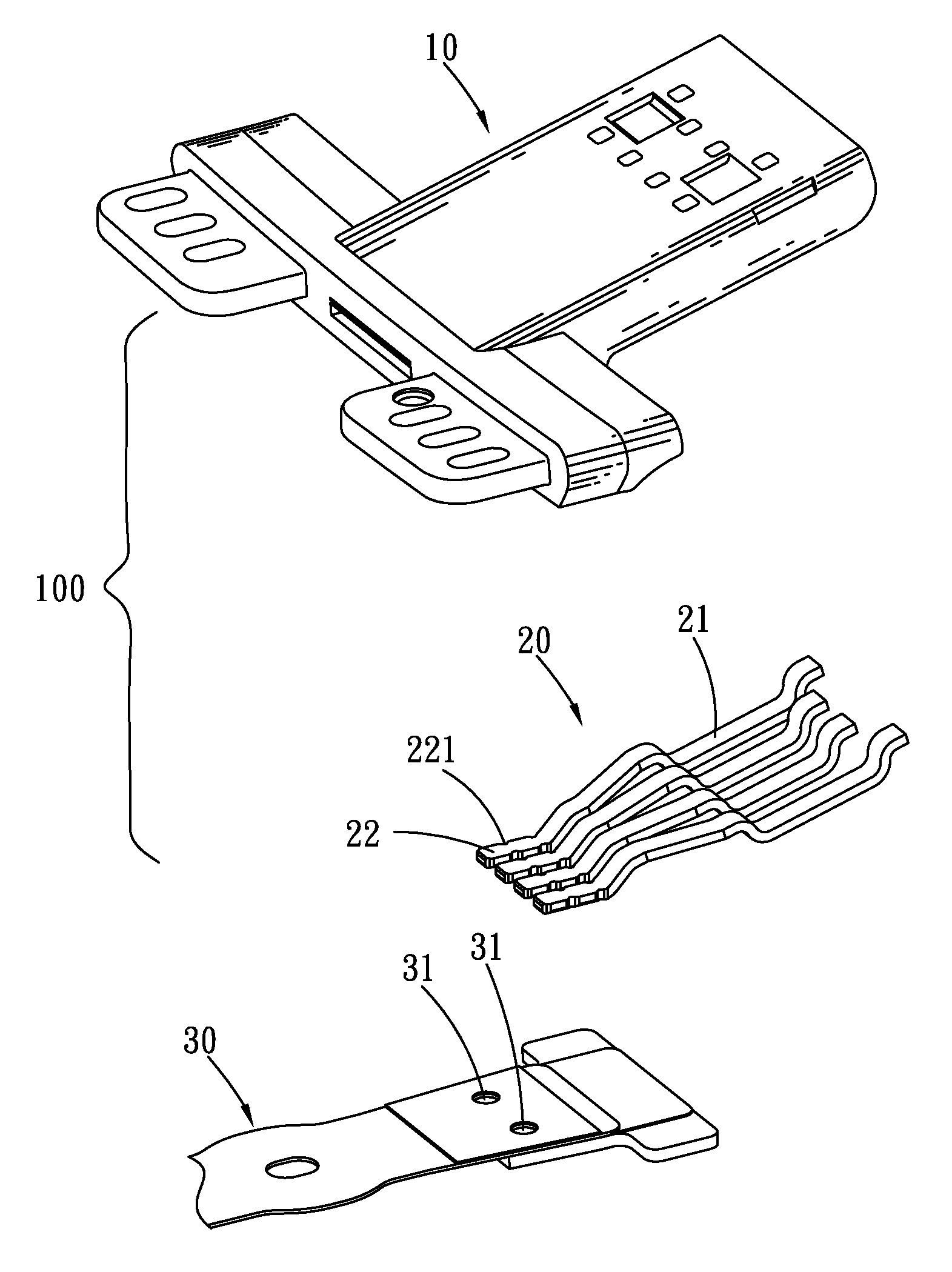

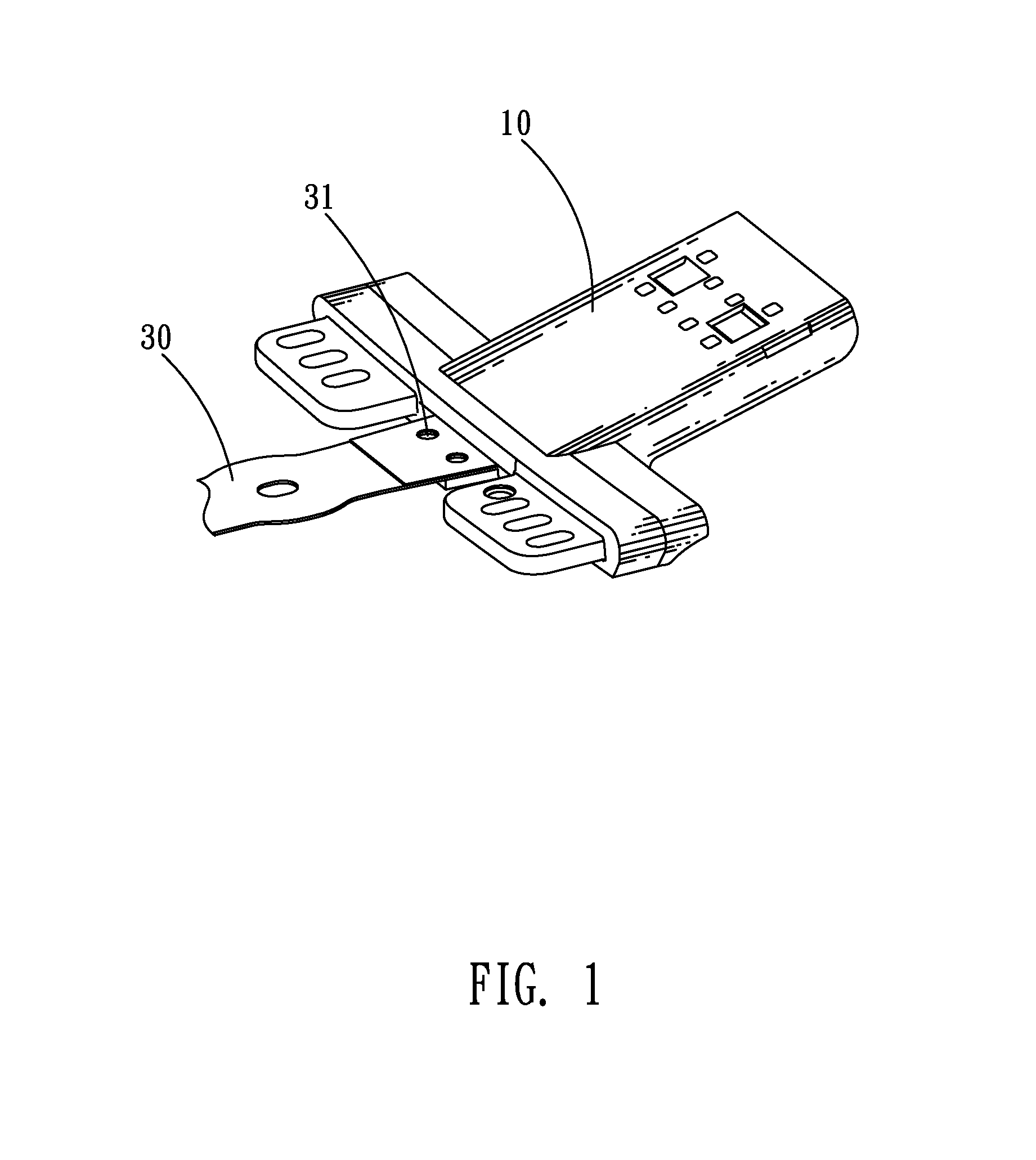

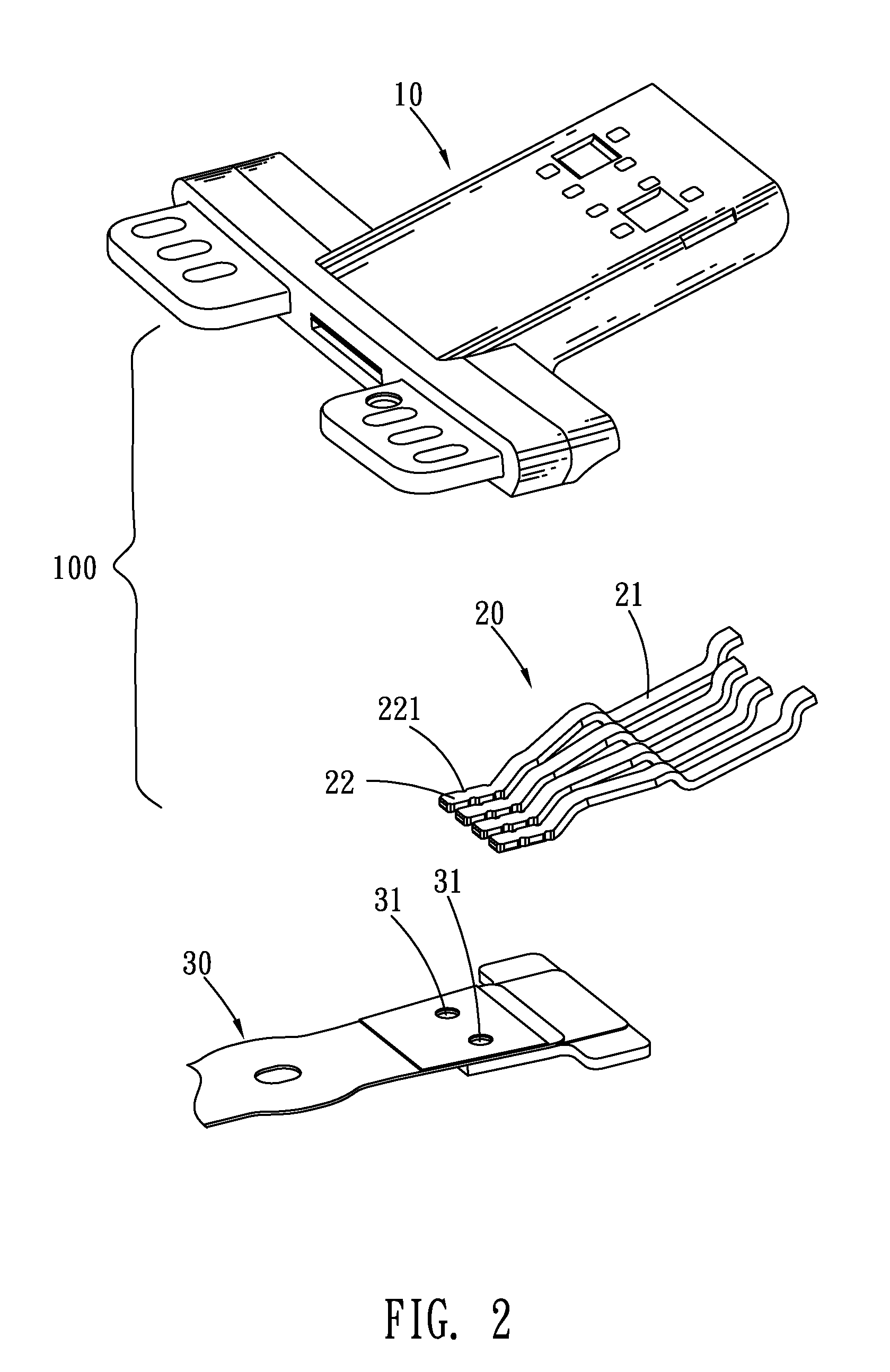

[0010]With reference to FIG. 1 and FIG. 2, a connector assembly according to an embodiment of the present invention includes a connector 100 and a FPC (Flexible Printed Circuit) board 30 electrically connected with the connector 100. The connector 100 includes an insulating body 10 and a plurality of terminals 20 soldered to one end of the FPC board 30 by means of solder press welding. Then the terminals 20 and the one end of the FPC board 30 soldered with the terminals 20 are together molded in the insulating body 10 once in a single mold (not shown).

[0011]Referring to FIG. 2, each of the terminals 20 has a contact arm 21 and a soldering tail 22 of which two side edges define a plurality of gaps 221 capable of gathering melted solder therein so as to strengthen the weld between the terminal 20 and the FPC board 30. The one end of the FPC board 30 soldered with the terminals 20 defines a plurality of positioning holes 31 used to securely position the FPC board 30 together with the term

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap