Electrical heating hookah

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

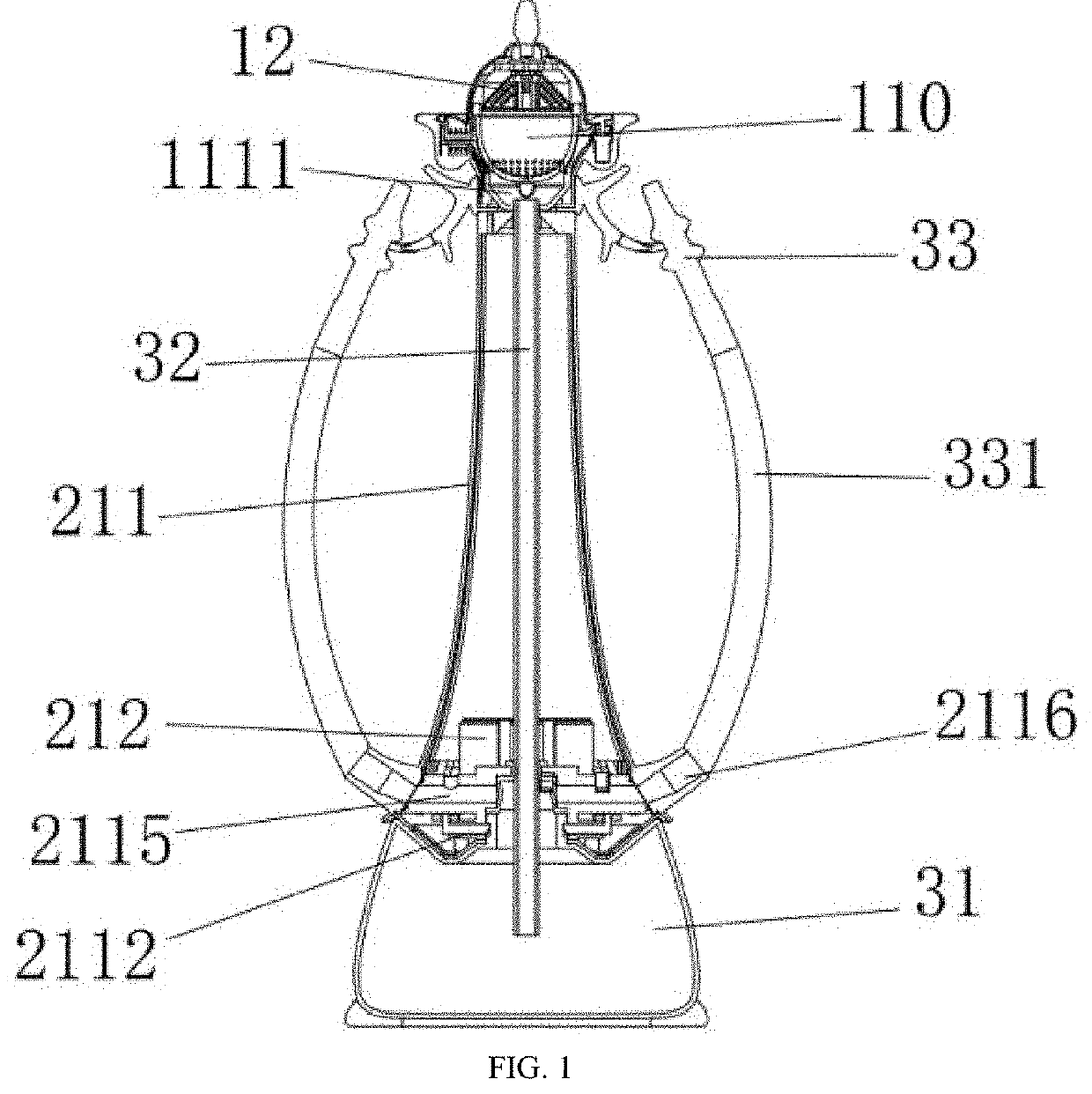

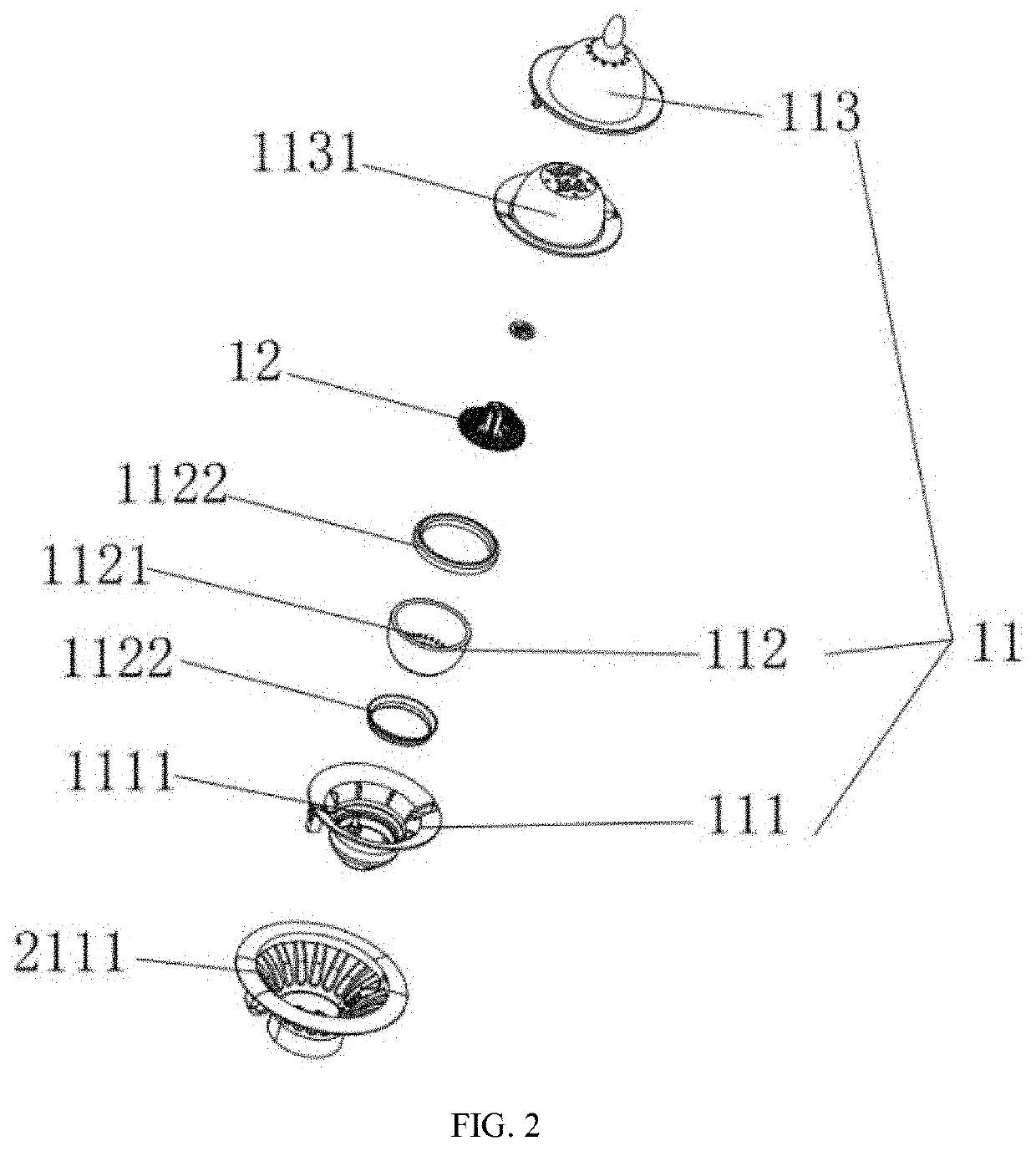

[0031]With reference to FIG. 2, as a first embodiment, the atomization component comprises a first main body 11 and a heating element 12; the first main body 11 is used to store prepared opium paste to be atomized, and the heating element 12 is used to heat and atomize the prepared opium paste in the first main body 11 to generate gas. In the embodiment, the heating element 12 is formed by winding a heating wire.

[0032]The first main body 11 comprises a base 111, a cup body 112, and a cup cover 113; the cup cover 113 and the cup body 112 cover together to form an atomization cavity 110 to accommodate the heating element 12; the cup cover 113 is detachably connected to the cup body 112 , which facilitates opening the cup cover 113 and adding prepared opium paste into the atomization cavity 110. In the embodiment, the cup body can be made of heat-resistant materials such as silica gel aluminum alloy tempered glass aluminum alloy, and the heating element can be made of electric heating wir

second embodiment

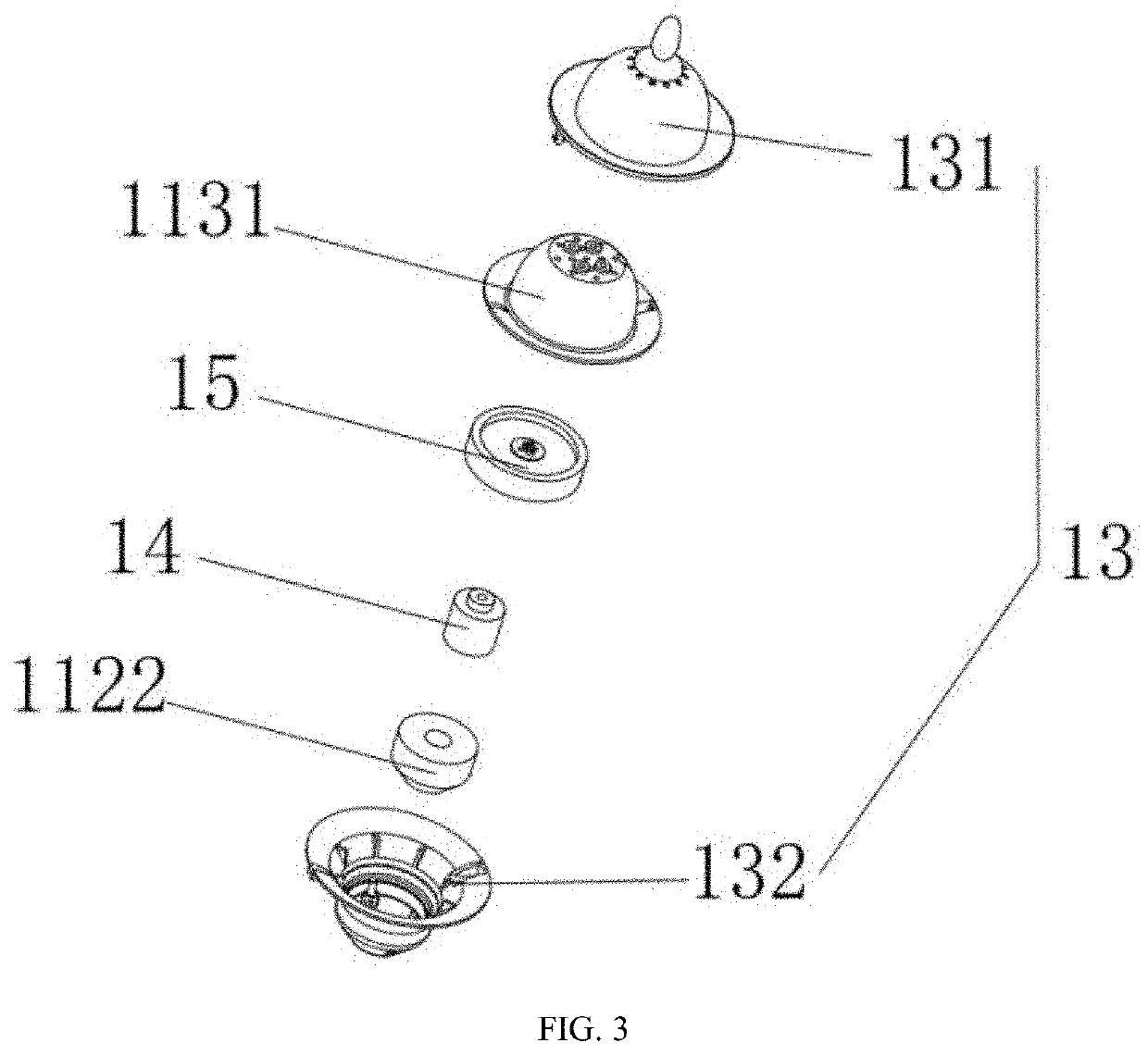

[0033]The bottom of the cup body 112 is provided with a plurality of vent holes 1121 that are communicated with the atomization cavity 110; the base 111 is provided with an accommodation cavity 1111 for accommodating the cup body 112, and the bottom end thereof is communicated with the pipe 32. The base 111 seals the bottom of the cup body 112 , so that the gas can enter the pipe 32 through the accommodation cavity 1111 after passing through the vent holes 1121. With reference to FIG. 3, as a second embodiment, the electrical heating atomization component comprises a second main body 13, and an electronic cigarette atomizer 14 and an electronic cigarette power supply 15 that are provided in the second main body 13; the electronic cigarette power supply 15 is electrically connected to the battery component and supplies power to the cigarette heating atomizer 14; the second main body 13 comprises an upper cover 131 and a lower cover 132 that are detachably connected; the lower cover 132

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap