Manual-and-electric switching-on switching-off dual-function permanent magnetic mechanism with protective chain

A technology of manual electric switching and permanent magnet mechanism, which is applied to the power device inside the switch, air switch parts and other directions, which can solve the problems of limited application, inability to switch universally, and narrow application area, and achieve a wide range of applications and universal use. Strong performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

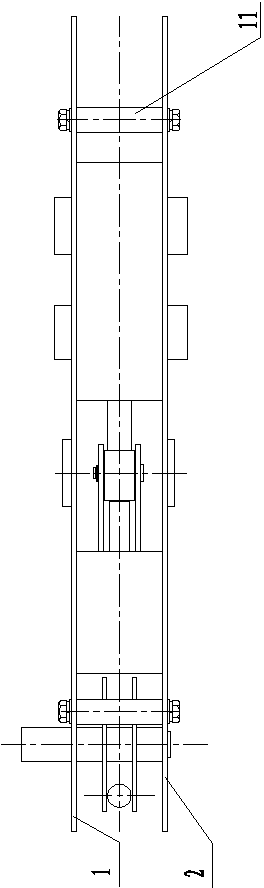

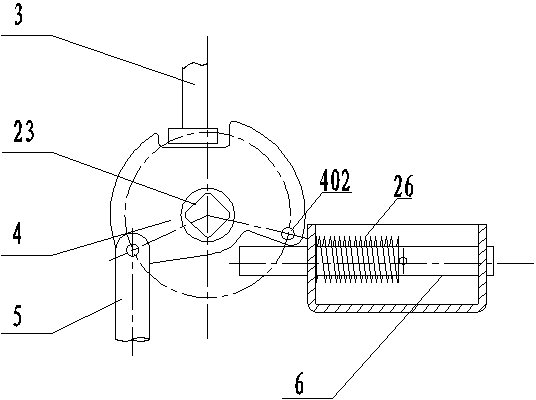

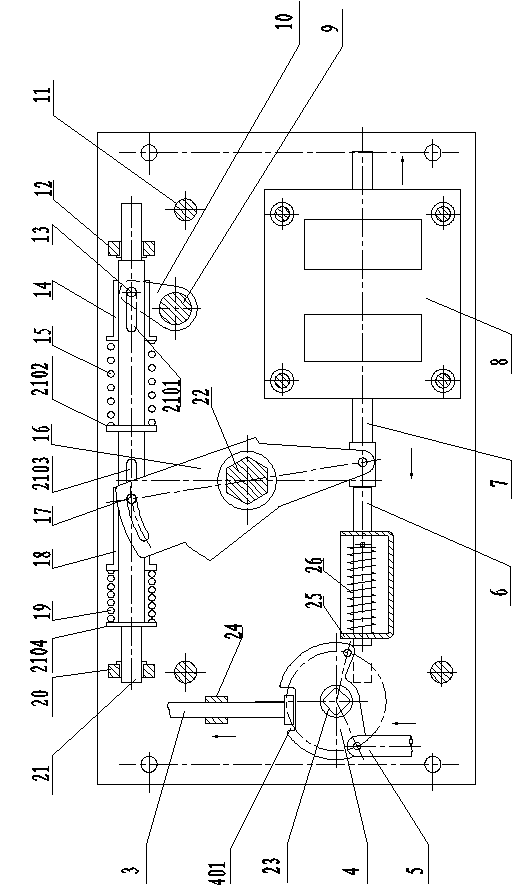

[0016] Such as figure 1 , figure 2 As shown, the present invention has front and rear side plates 1 and 2 of the mechanism. A support 11 and a spindle 22 are provided between the front and rear side plates 1 and 2 of the mechanism. In this example, the support 11 uses a support rod to ensure the front , There is enough installation space in the middle of the rear side plate. On the left side of the front and rear side plates 1 and 2 of the mechanism, there are isolation switch interlock lever 3, protective interlock arm 4, interlock operating shaft 23, grounding switch interlock lever 5 and resettable Interlock limiting shaft 6, interlock operating shaft 23 is located in the center of the protective interlocking arm 4, the resettable interlocking limiting shaft 6 is installed in the box body 25 and covered with a spring 26, the isolation switch interlocking lever 3 is located above the protective interlocking arm 4 , There are limit sleeves 24 on the front and rear side panels 1 a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap