Support assembling and locating sleeve

A technology of positioning sleeves and sets, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of no positioning device, too simple positioning method, and easy deviation in the positioning process, so as to achieve simple and compact structure and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be further clarified below in conjunction with the drawings and specific embodiments.

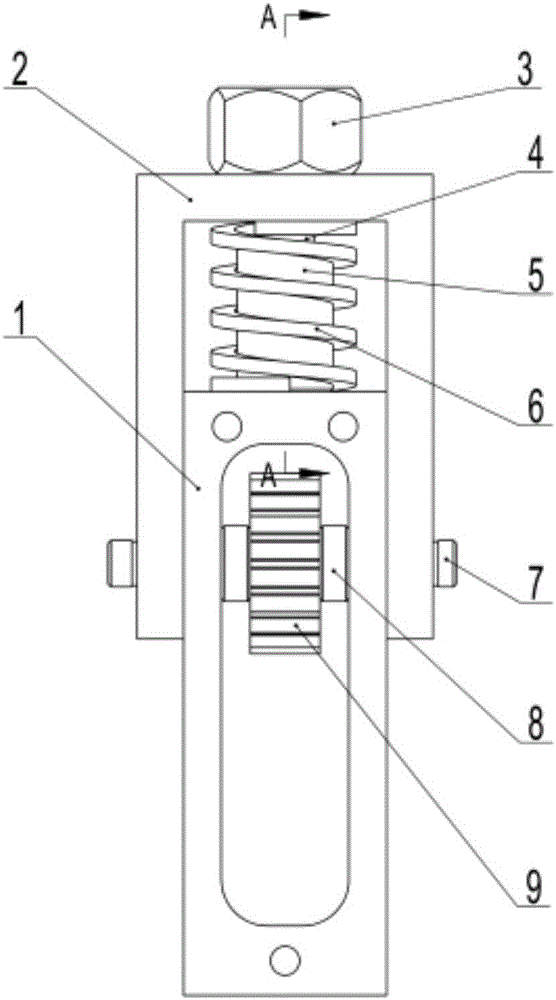

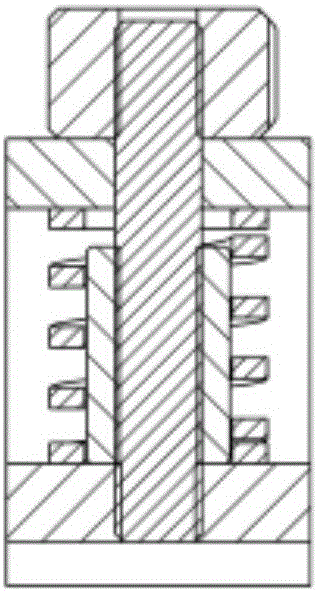

[0014] Such as Figure 1-2 As shown, the bracket is assembled with a positioning sleeve, including a pre-deformed bracket 1, a positioning sleeve 2, a nut 3, a screw 4, a nut bracket adjustment block 5, a spring 6, a shaft pin 7, a spacer 8 and a gear 9.

[0015] The positioning sleeve 2 is U-shaped, and the positioning sleeve 2 is sleeved on the pre-deformed support 1 through the shaft pin 7. After mating, the positioning sleeve 2 and the pre-deformed support 1 form an adjustment area; the gear 9 is set in the pre-deformed through the shaft pin 7 In the support 1, spacers 8 are provided on both sides of the gear 9.

[0016] A nut 3 is provided on the upper part of the positioning sleeve 2, and the nut 3 is fixed by a screw 4 passing through the positioning sleeve 2 into the adjustment area. A nut bracket adjustment block 5 is sleeved on the outer periphery of the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap