System and method for remote monitoring of equipment moisture exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

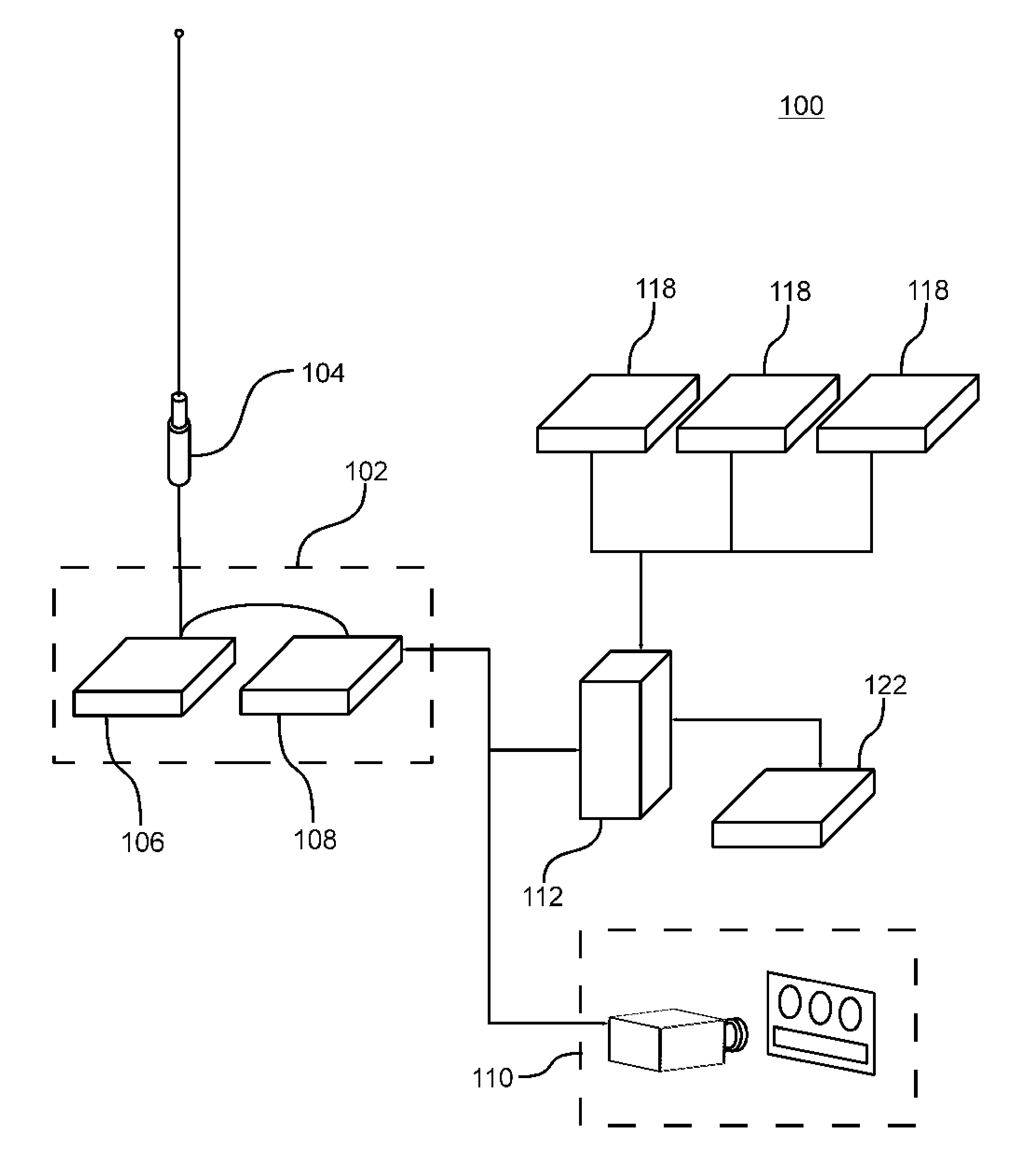

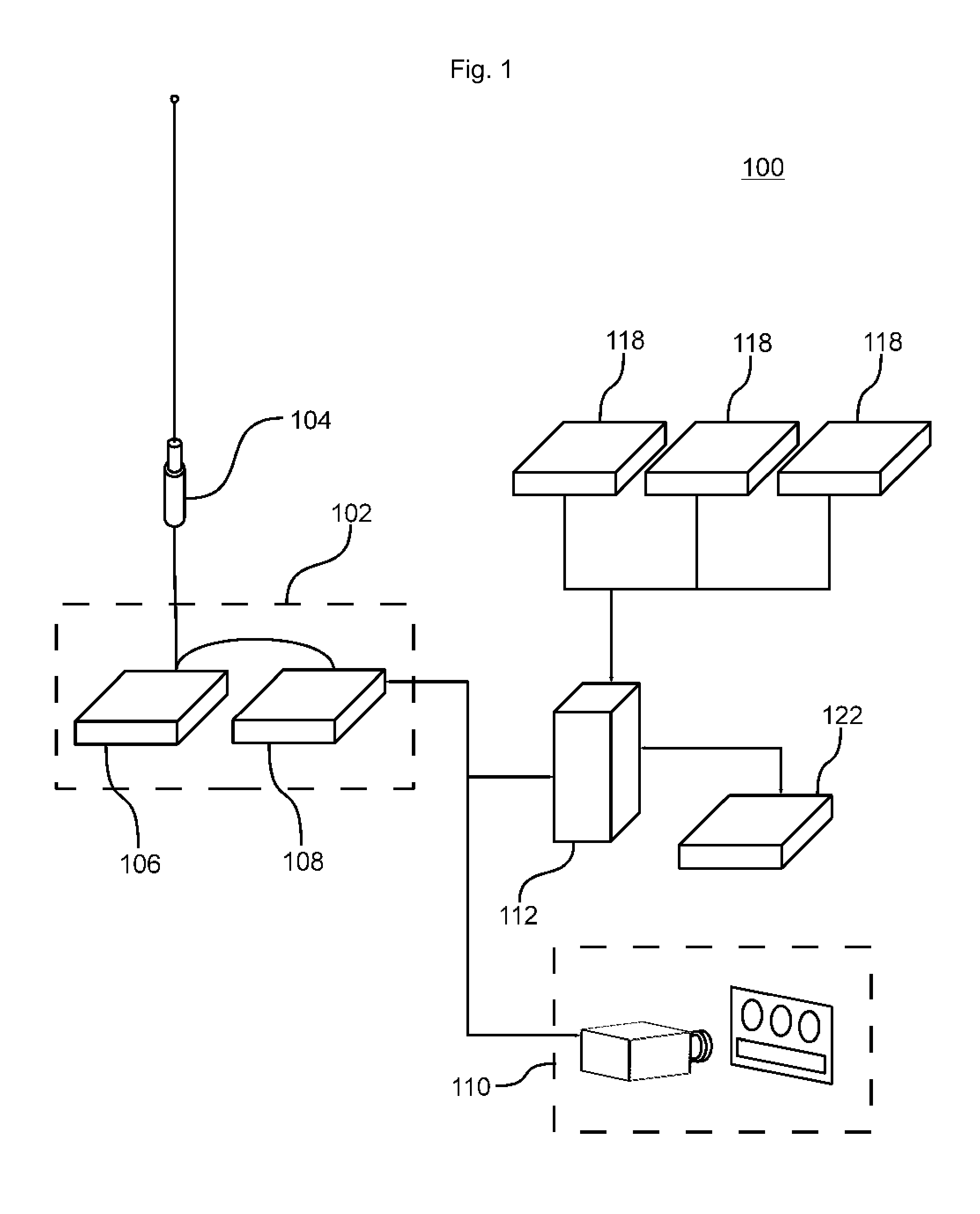

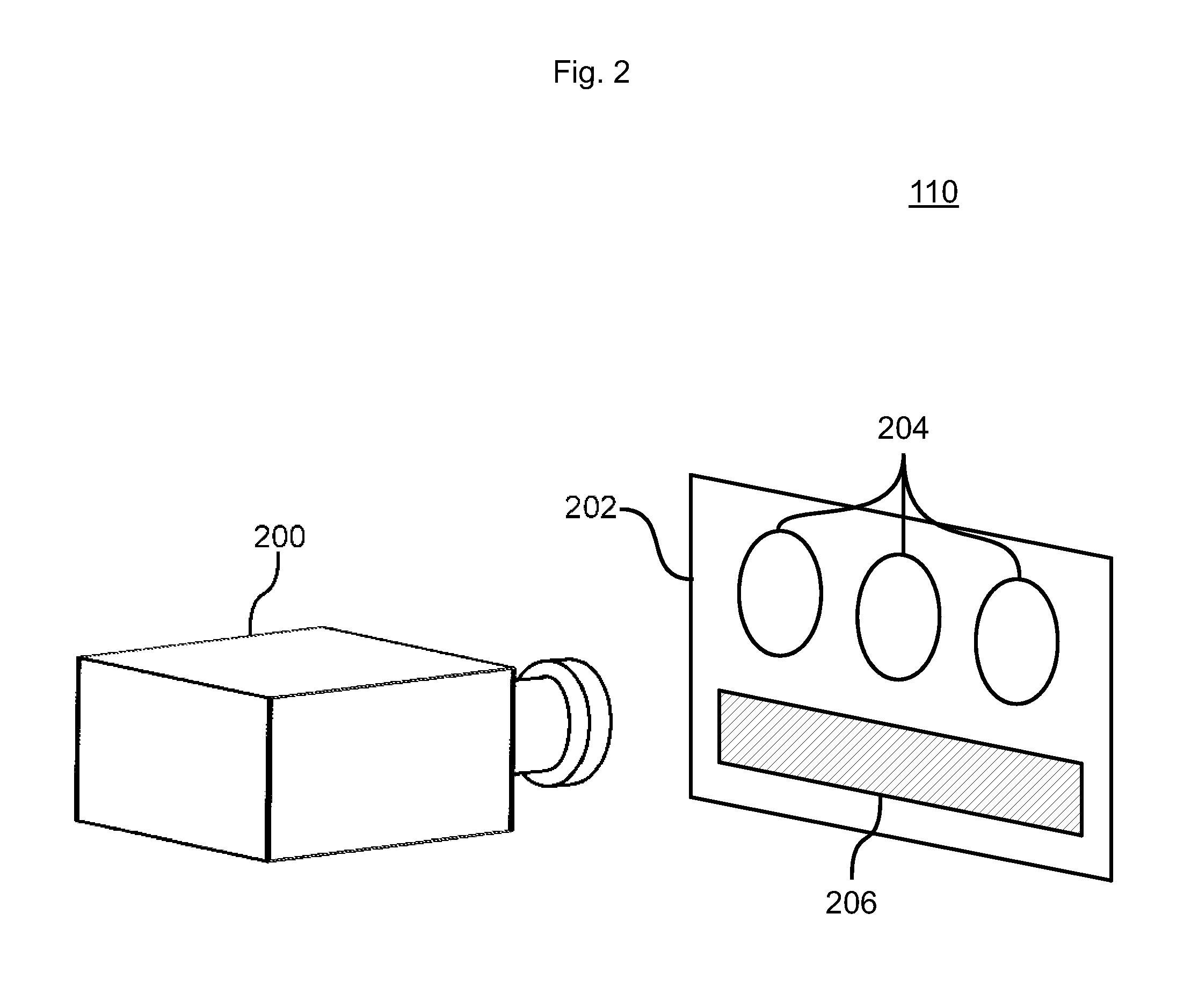

[0020]Illustrative embodiments of the present principles are disclosed herein. However, techniques, systems and operating structures in accordance with the present principles may be embodied in a wide variety of forms and modes, some of which may be different from those in the disclosed embodiment. Consequently, the specific functional details disclosed herein are merely representative, yet in that regard, they are deemed to afford the best embodiment for purposes of disclosure and to provide a basis for the claims herein which define the scope of the present principles.

[0021]Some elements of the present principles are illustrated as modules for performing described functions. While these modules may be described in terms of software implementations, any hardware, or combination of hardware and software may be used to implement the present principles without deviating from the scope or spirit thereof.

[0022]Moreover, well known methods and procedures for both carrying out the objectives

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap