Reference current source circuit and system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

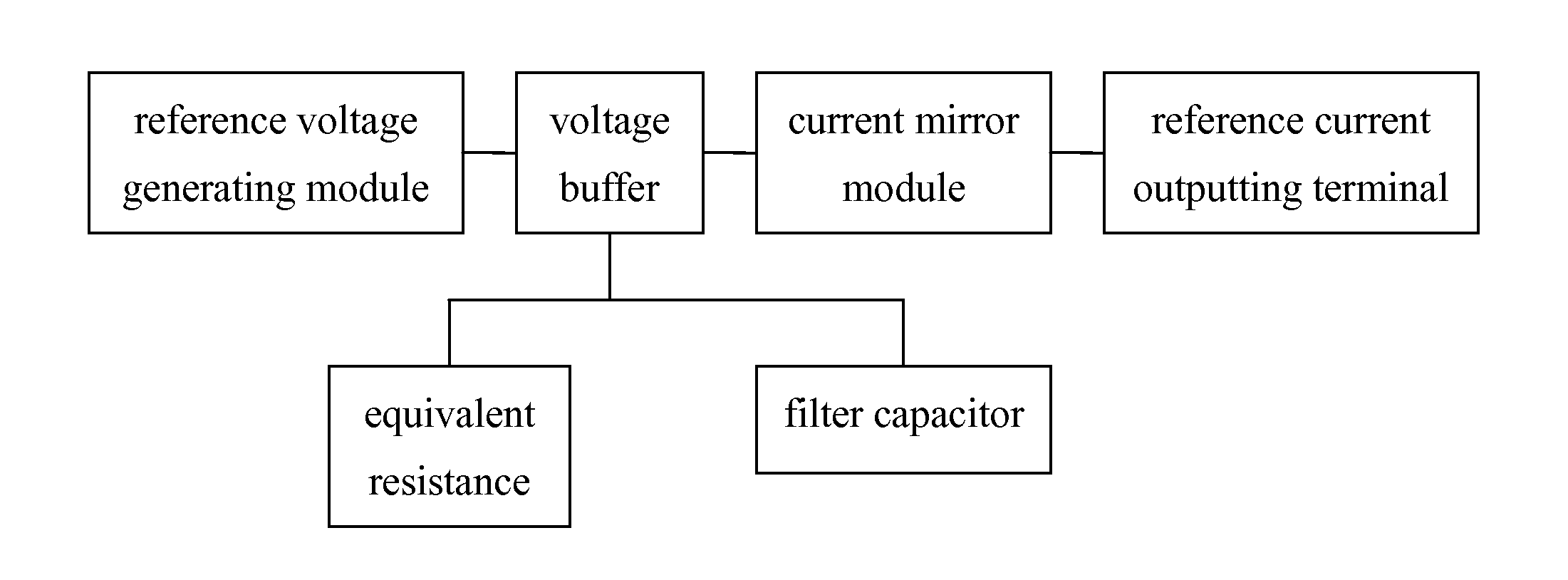

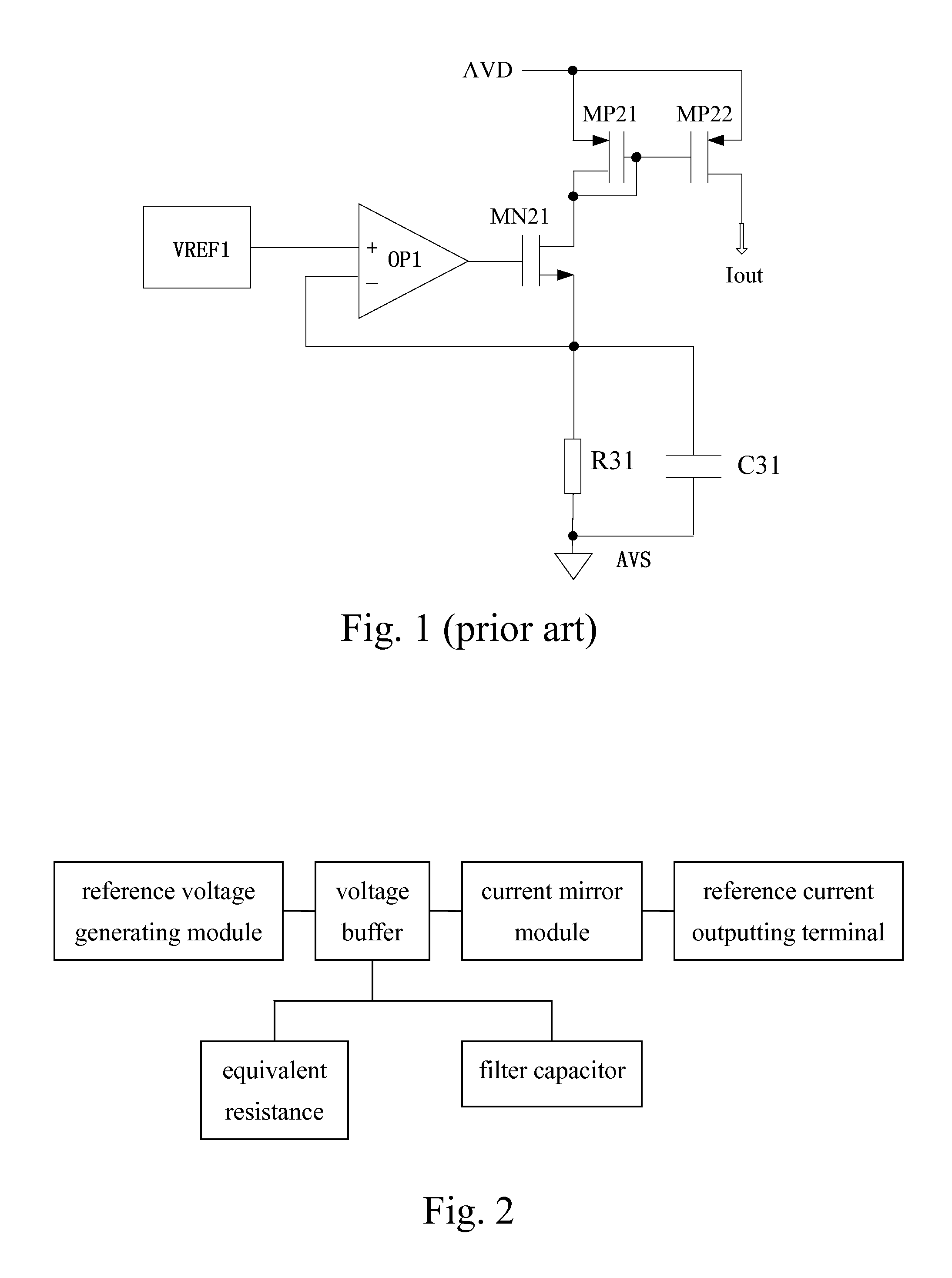

[0014]Referring to FIGS. 2 and 3 of the drawings, a reference current source circuit and its system according to a preferred embodiment of the present invention are illustrated, comprising a reference voltage generating module VREF, a voltage buffer connected to the reference voltage generating module VREF, an equivalent resistor connected to the voltage buffer, a filter capacitor C1 connected to the voltage buffer, a current mirror module connected to the voltage buffer and a reference current outputting terminal lout connected to the current mirror module, wherein the voltage buffer comprises an operational amplifier OP and a first FET M1 connected to the operational amplifier OP; the current mirror module comprises a second FET M2 and a third FET M3 connected to the second FET M2; the equivalent resistor comprises an oscillator OSC, a fourth FET M4 connected to the oscillator OSC, a fifth FET M5 connected to the oscillator OSC and a capacitor C2 connected to the fourth FET M4 and th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap