Method of detecting and signalling a hot box condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

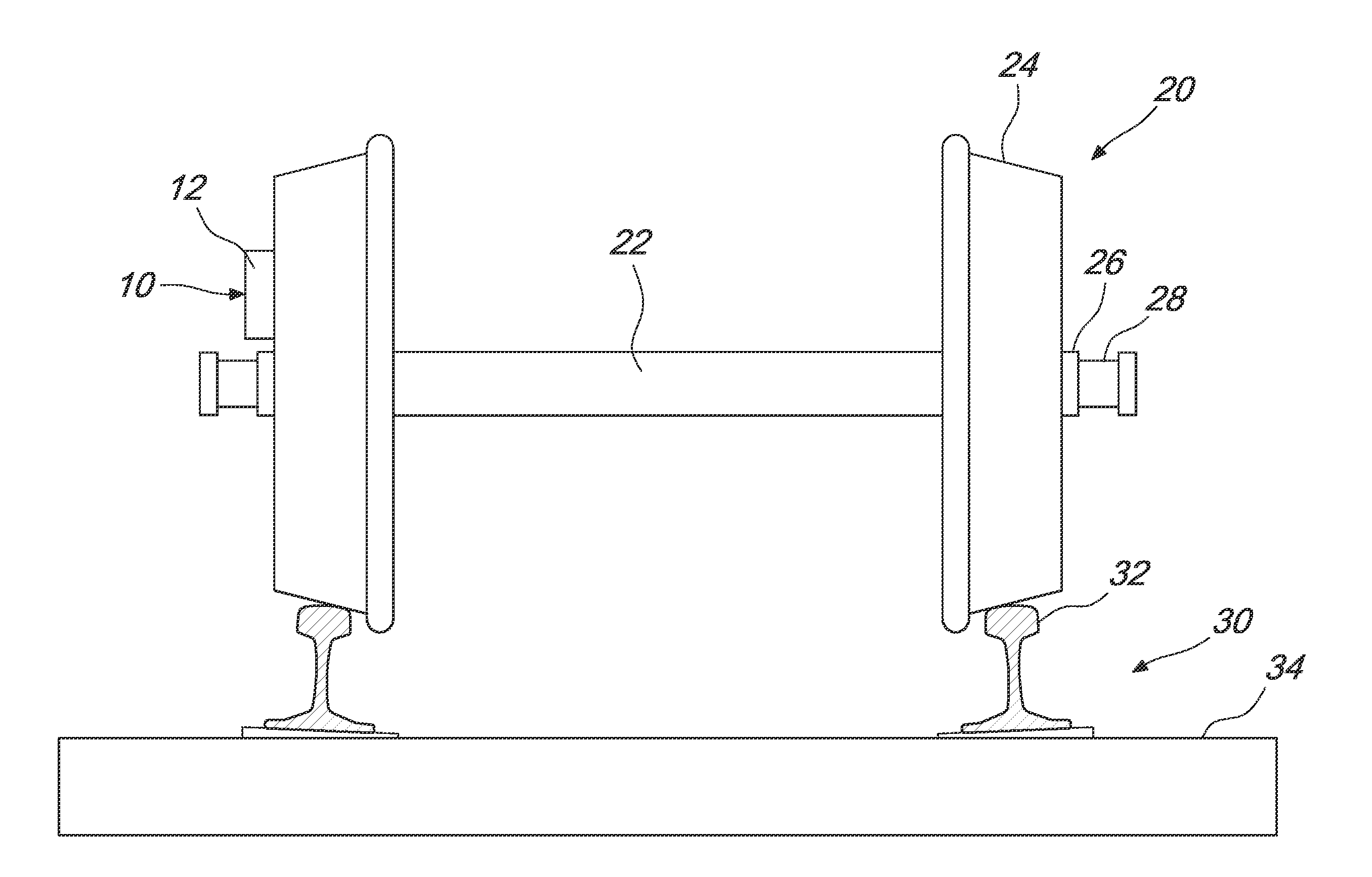

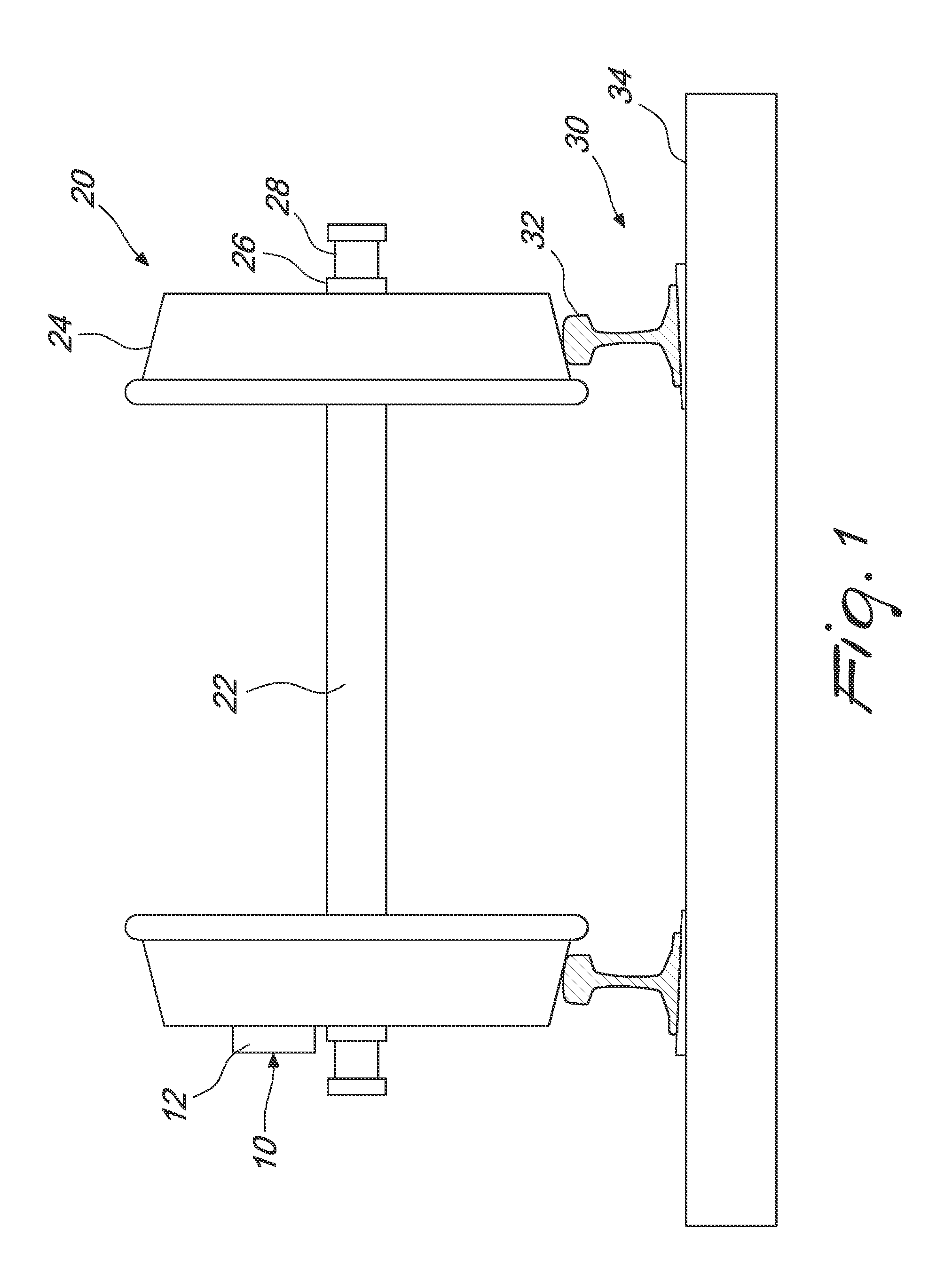

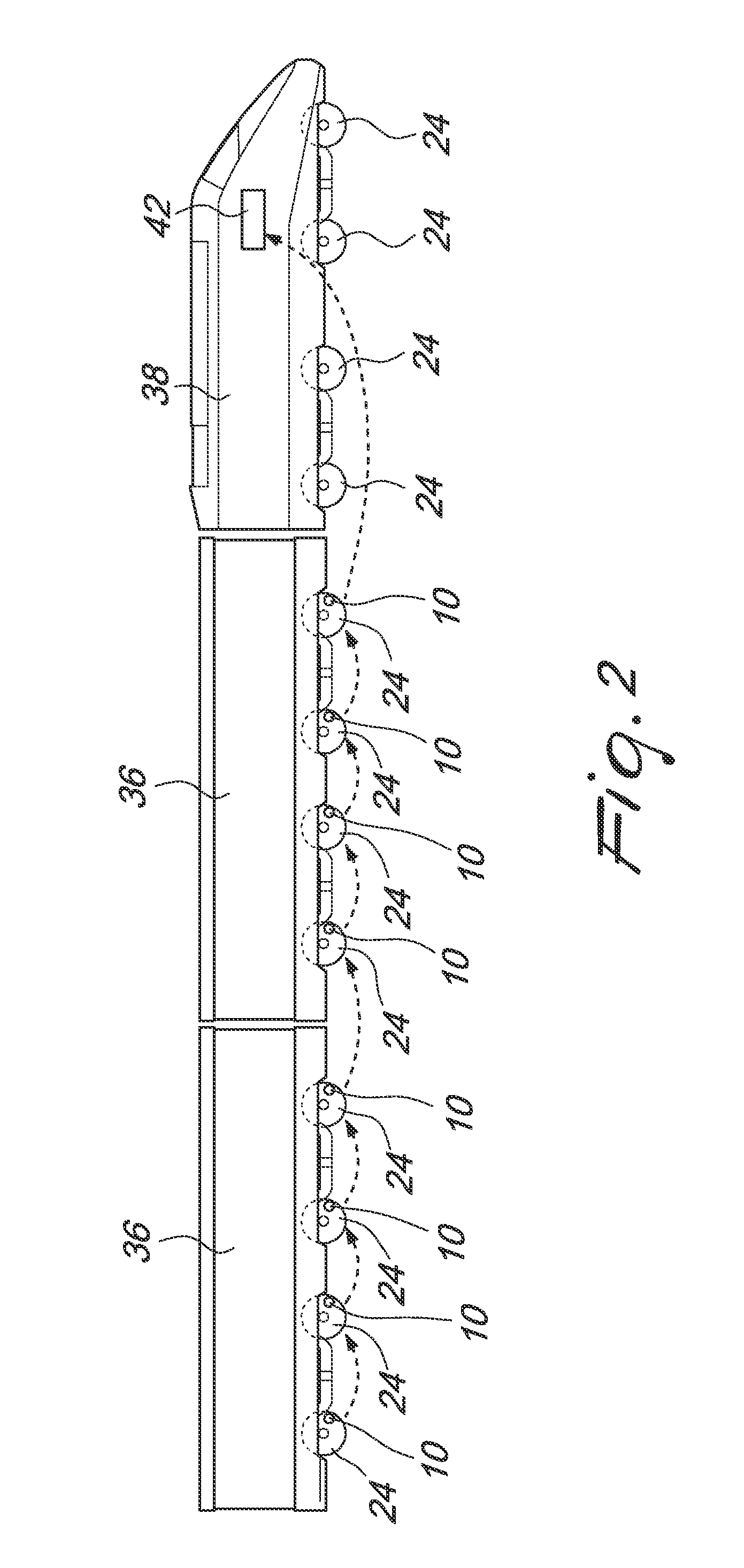

[0013]This disclosure generally relates to a device 10 for detecting a hot box / hot wheel condition on a rail vehicle undercarriage component.

[0014]With reference to FIG. 1, the hot box detection device 10 may comprise a housing 12. The housing 12 may have a container-like structure. The housing 12 may have a structure to accommodate the temperature sensor and any required electronics. The housing 12 may be configured so as to be positioned on an undercarriage component of a rail vehicle. The housing 12 may have a suitable shape and structure to be positioned on the undercarriage component. The housing 12 may be composed of thermal insulation materials.

[0015]The device 10 may be coupled to the undercarriage component. The housing 12 may be coupled to directly on the undercarriage component. The housing 12 may be suitably coupled to the undercarriage component. In an embodiment, the housing 12 may be removably coupled to the undercarriage component. The housing 12 may be magnetically c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap