Anode device and maintenance method

a technology of anode and maintenance method, which is applied in the field of anode device and maintenance method, can solve the problems of seawater escape from the cooling system, contaminating or corroding other nearby components, and difficult withdrawal of brass fittings containing zinc from the port, so as to facilitate the installation and replacement of anodes, minimize or prevent the escape of fluid, and minimize the effect of seawater escap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

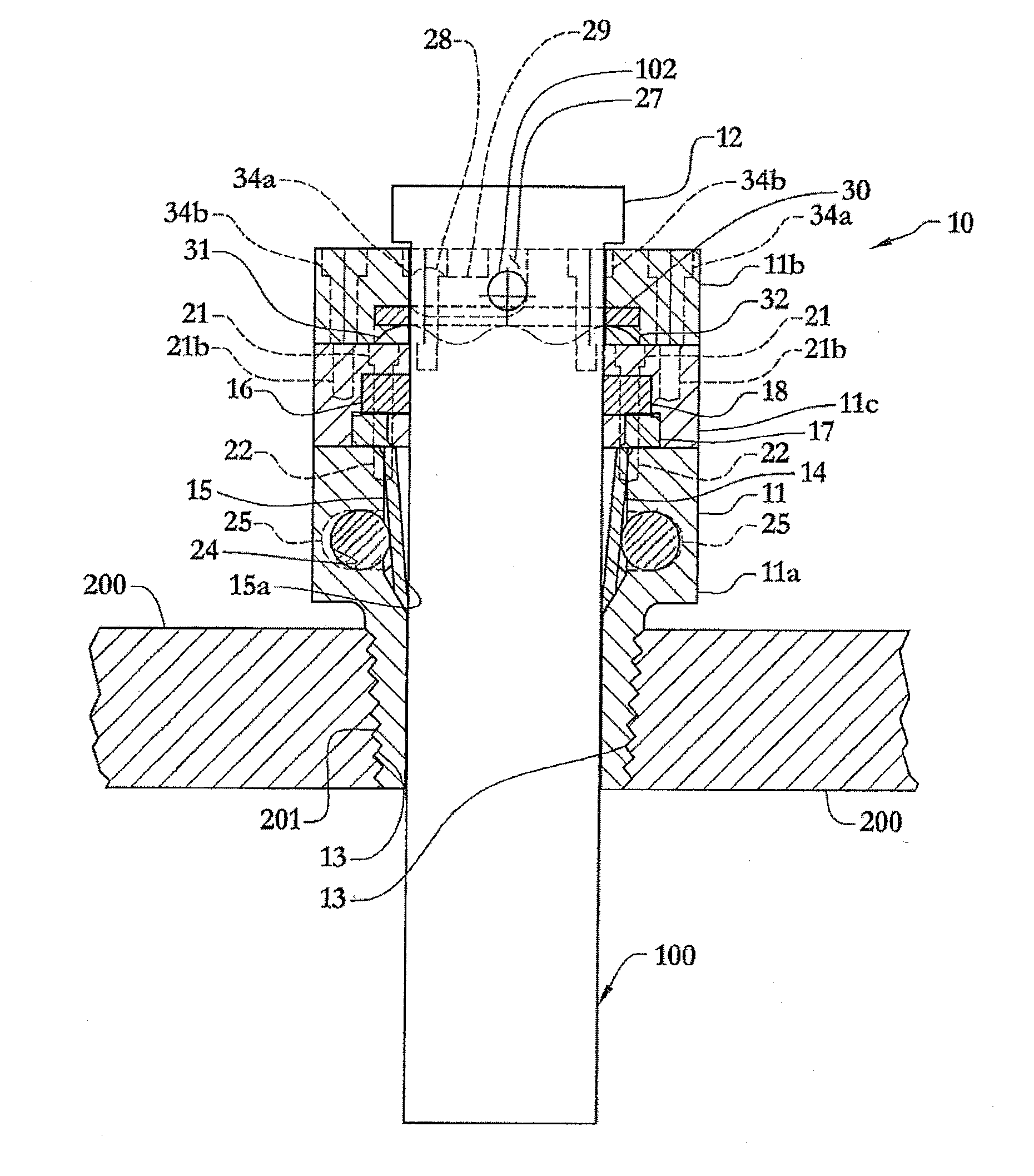

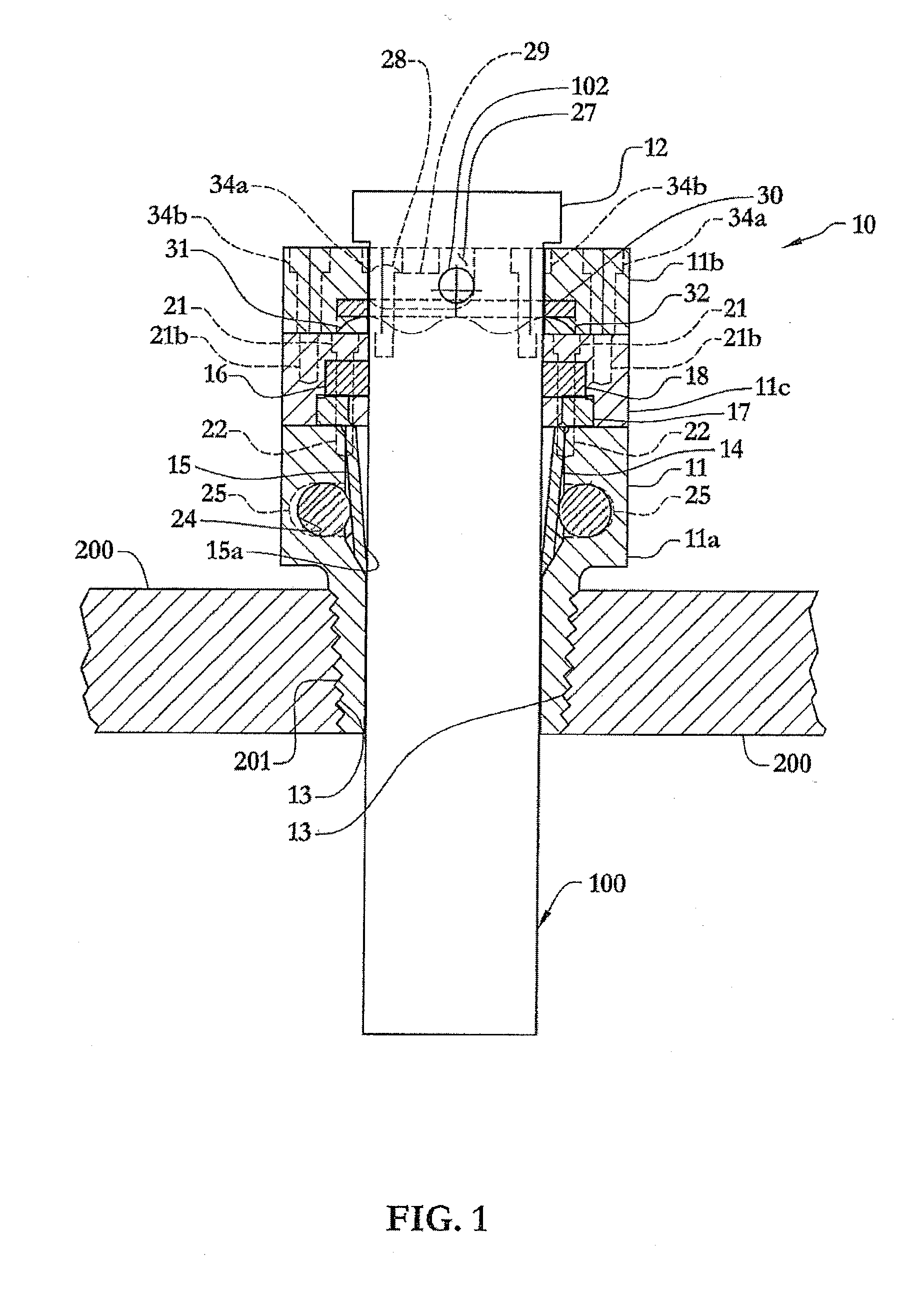

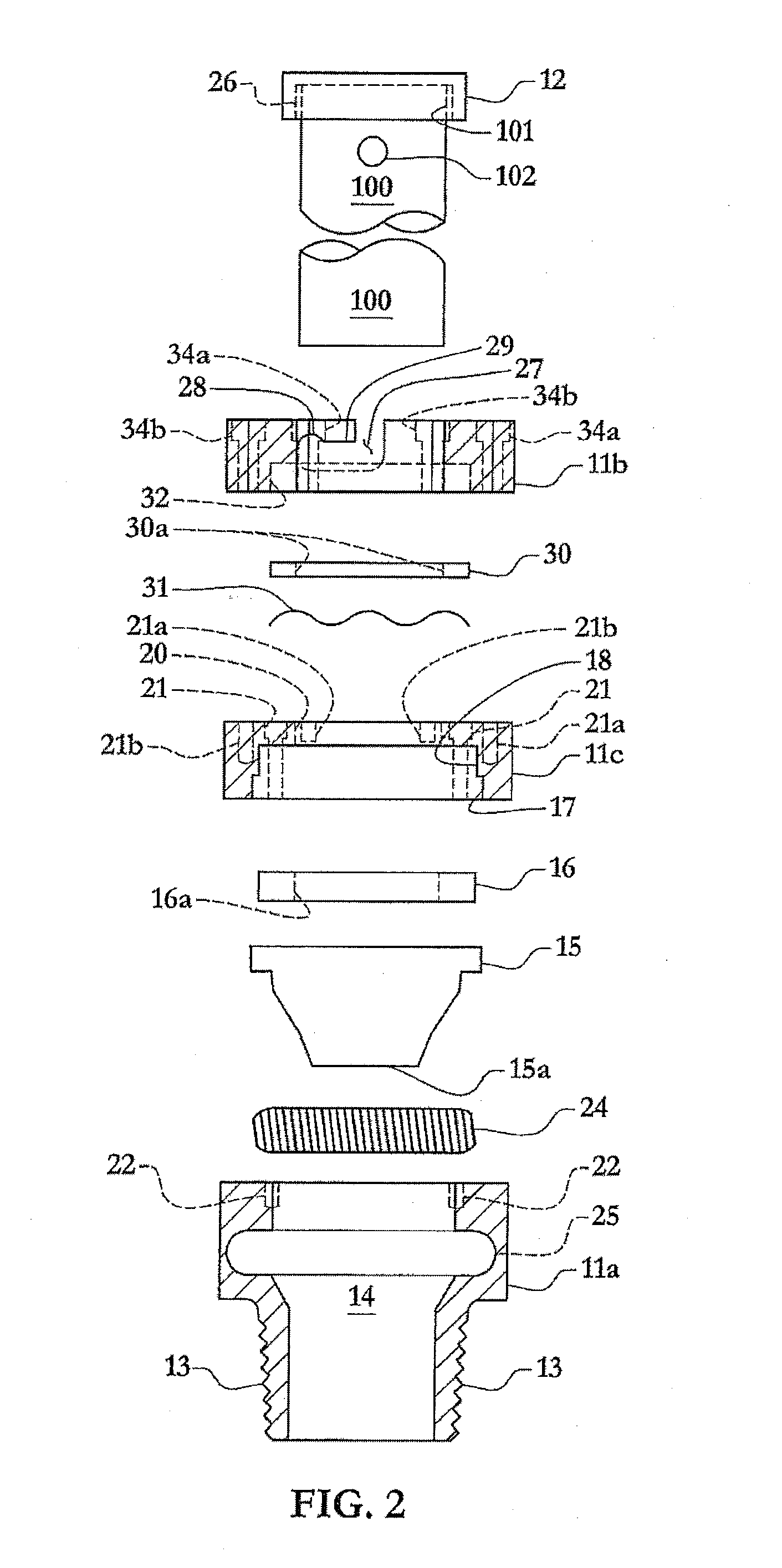

[0034]Referring to FIG. 1, a preferred embodiment of an anode plug device 10 is shown with an anode 100 held therein. The anode plug device 10 is shown according to a preferred embodiment having a connector 11 that has a channel therethrough. According to a preferred embodiment, the connector 11 is illustrated having a lower body portion 11a, an upper body portion 11b, and a connecting portion lie. The connector 11 preferably has a threaded portion 13 that is matingly threaded for connection to a threaded bore 201 of an engine cooling system component, such as the pipe 200 (or other structure to which the device 10 is mounted). The connector 11 preferably has sealing means comprising a sealing mechanism for sealing the passage of seawater from escaping through the connector 10 when the anode 100 is removed. The sealing mechanism preferably comprises a sealing component. According to some embodiments, the sealing component may comprise a spring-loaded wafer valve. According to other emb

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap