Intake Module for an Internal Combustion Engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

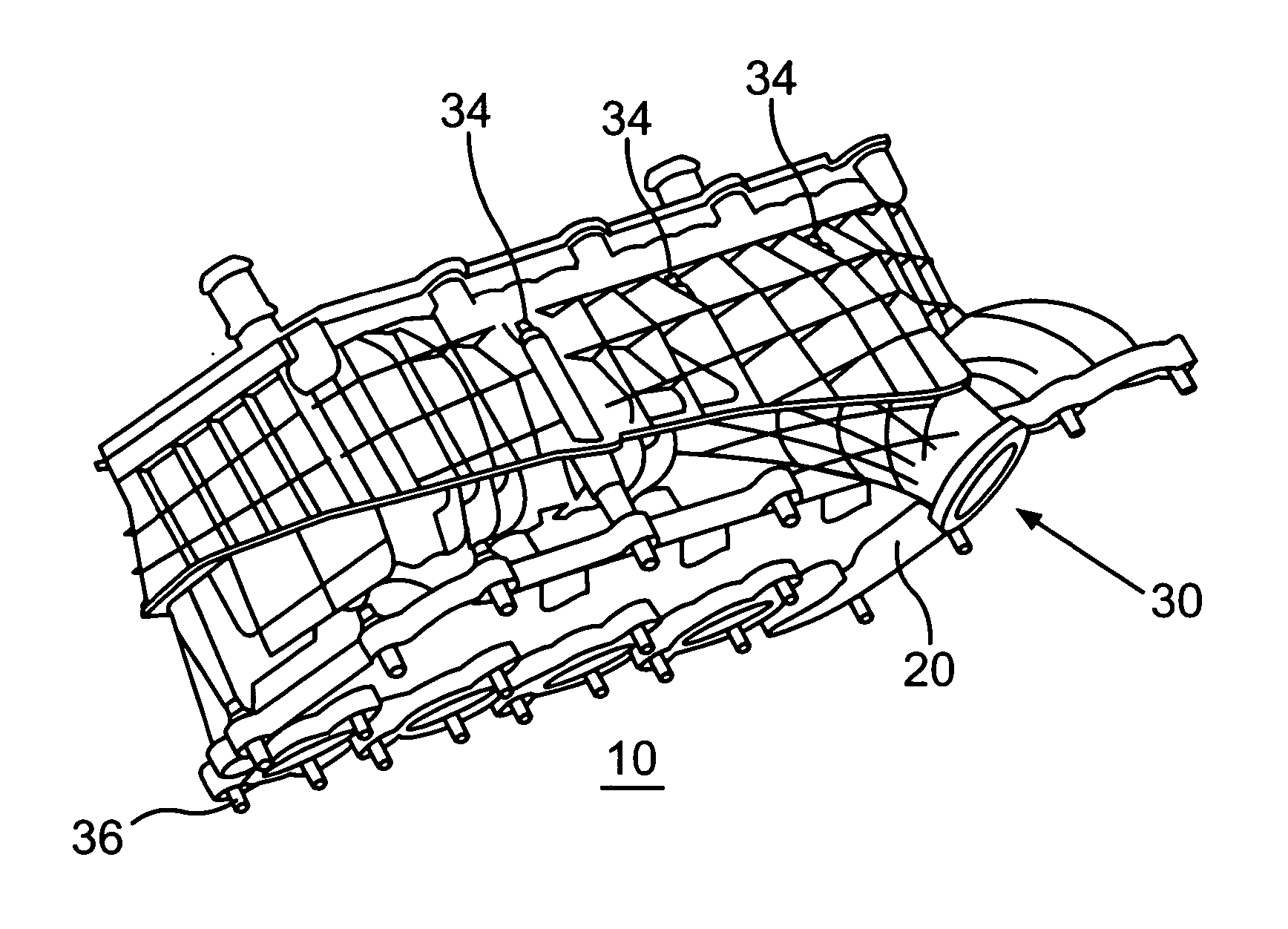

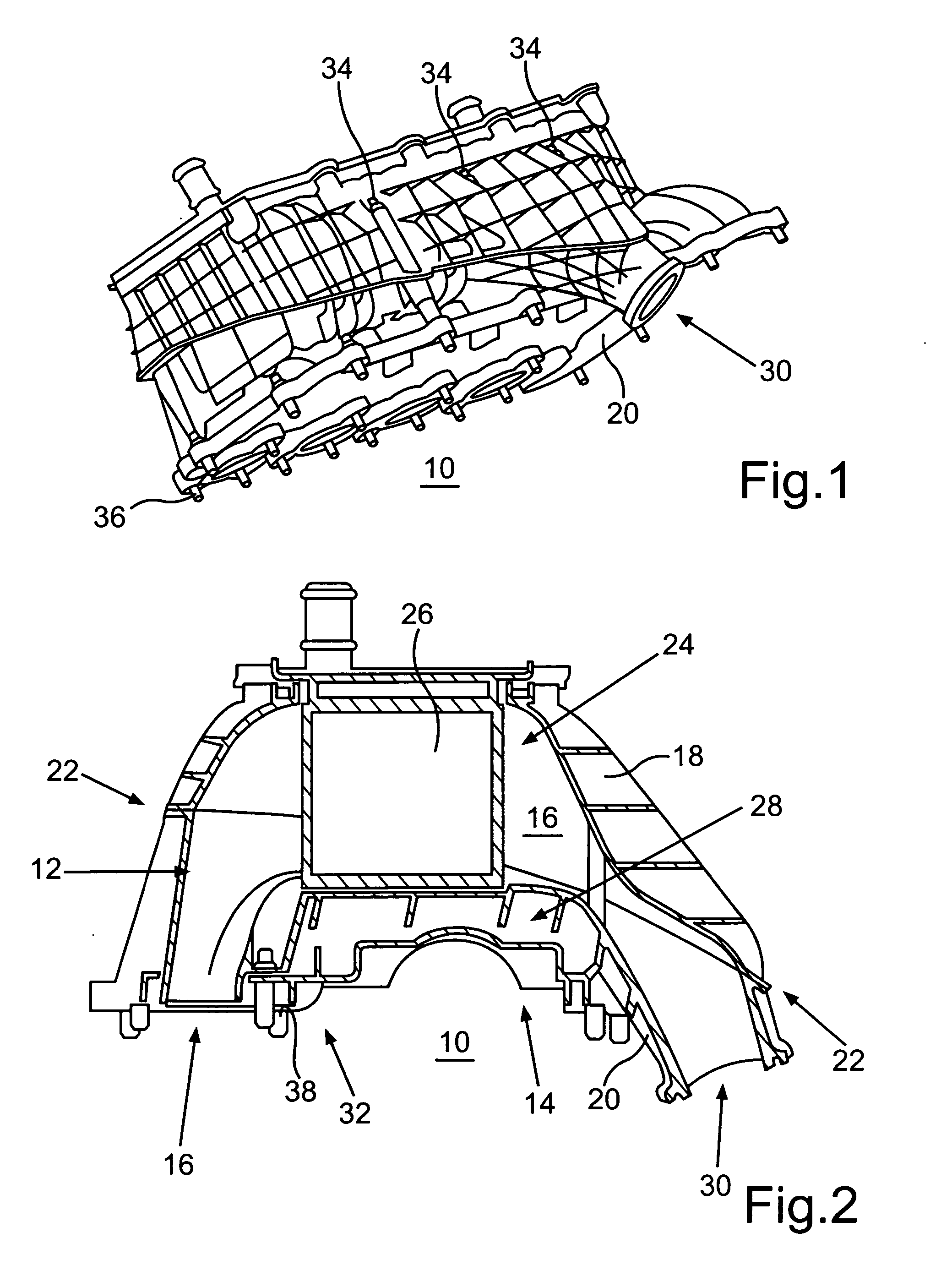

[0026]FIG. 1 shows an intake module 10 for an internal combustion engine designed as a reciprocating piston internal combustion engine of a motor vehicle, in particular a passenger vehicle. As is apparent in conjunction with FIG. 2, the intake module 10 includes an air duct element 12 by means of which air is to be supplied to the internal combustion engine. The air duct element 12 is therefore also referred to as an intake manifold, since the internal combustion engine may draw in air via the air duct element.

[0027]The intake module 10 also includes a cylinder head cover 14 by means of which a cylinder head of the internal combustion engine is to be at least partially covered, and which is designed in one piece with the air duct element 12. Associated with the air duct element 12 are air channels 16 via which the air is able to flow into cylinders of the internal combustion engine, and which are partially delimited on the one hand by an upper housing part 18 of the intake module 10 an

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap