Chassis for Rail Vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

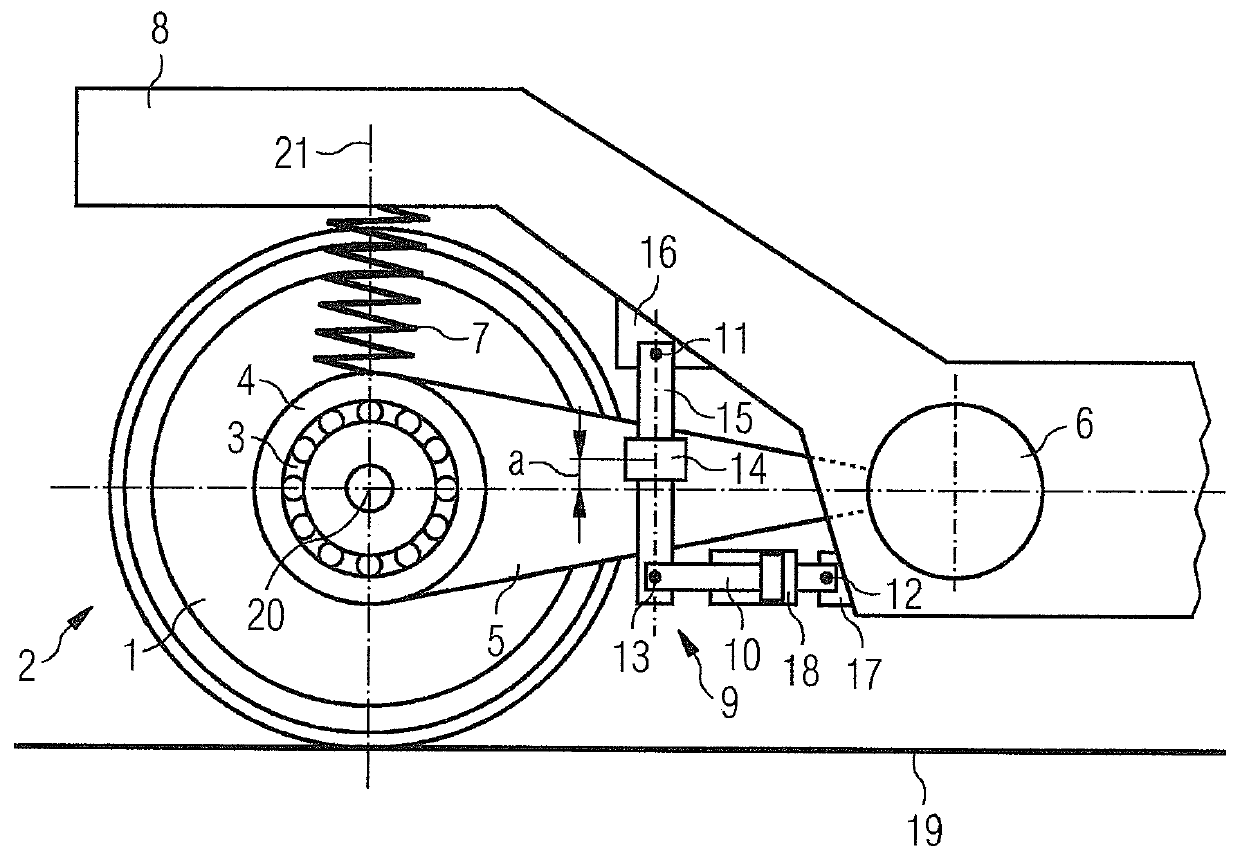

[0018]A detail, shown in a side view in the FIGURE, of an exemplary embodiment of a chassis in accordance with the invention of a rail vehicle comprises a detail of a support structure 8 as well as a first wheel 1, which lies against a track 19.

[0019]The support structure 8 is formed as a chassis frame with sole bars and a cross member. In accordance with the invention, with regard to geometry, connection technology, or materials, different embodiments of support structures 8 are conceivable.

[0020]The support structure 8 may be formed / structured as one part or as multiple parts. In multipart embodiments, it is possible, for instance, to interconnect individual parts in an articulated manner, etc.

[0021]The first wheel 1 is arranged around a crossarm 20 and connected to a first wheelset shaft (not shown) which extends along the crossarm 20. Arranged on the first wheelset shaft is a first wheel bearing 3, which is shrouded by a first wheel bearing housing 4.

[0022]The first wheel bearing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap