Apparatus and method for producing a plastic bottle and for filling it with a filling product

a technology for plastic containers and filling products, which is applied in the directions of transportation and packaging, packaging goods, other domestic articles, etc., can solve the problems of filling product foaming or spurting, and achieve the effect of improving the efficiency of the filling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077]Examples of embodiments are described below with the aid of the figures. In the figures, elements which are identical or similar, or have identical effects, are designated with identical reference signs, and repeated description of these elements is in part dispensed with in the description below, in order to avoid redundancy.

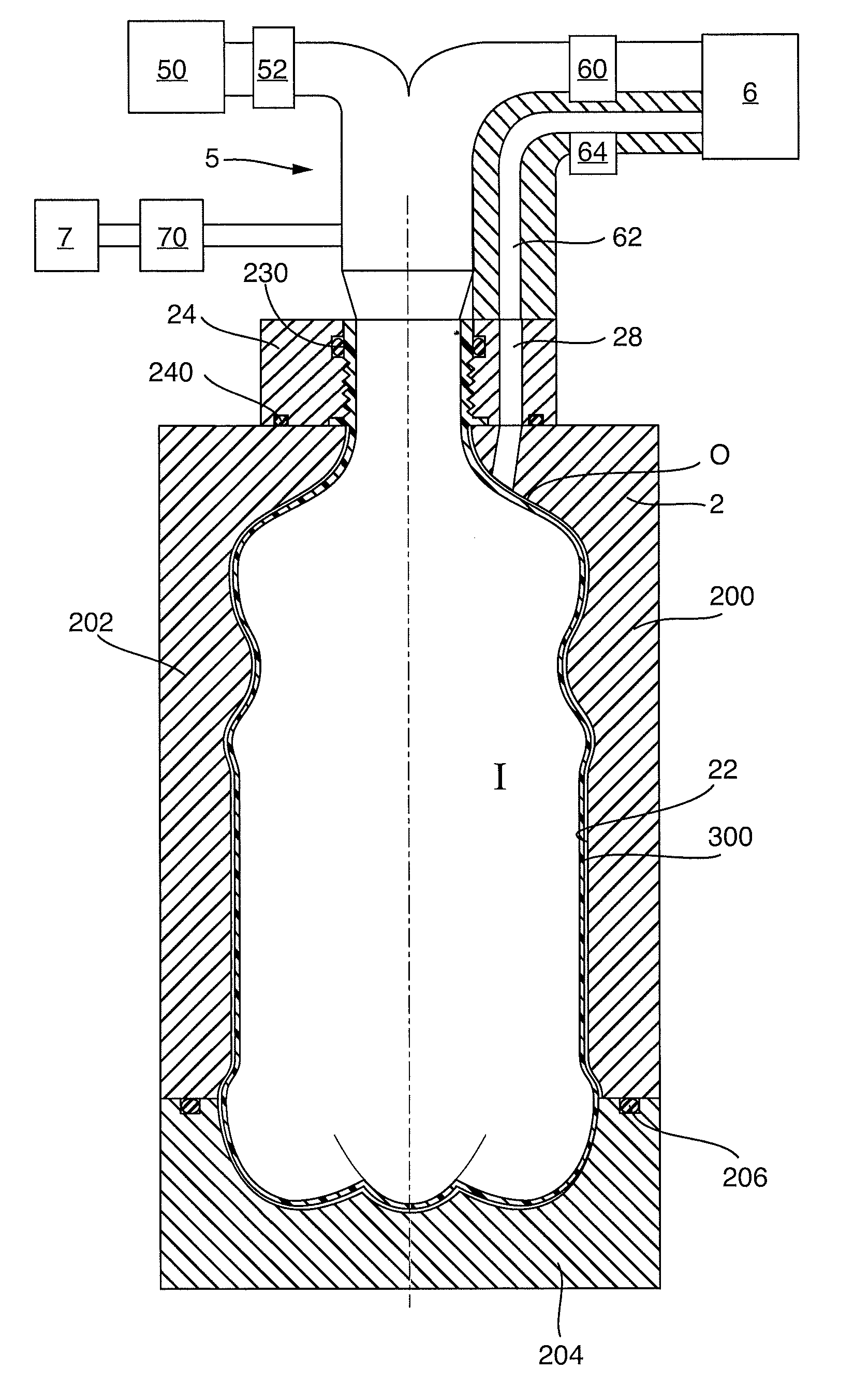

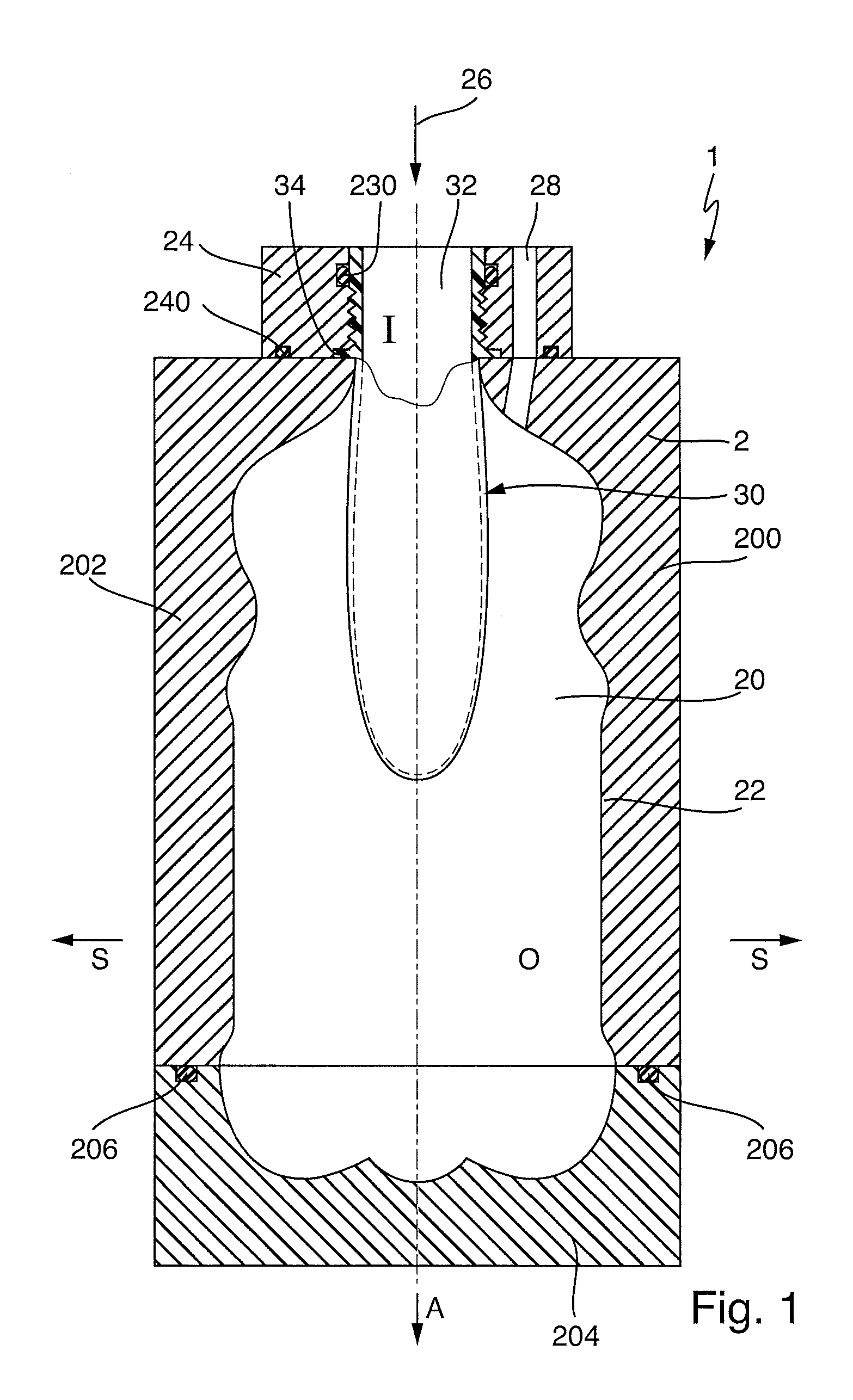

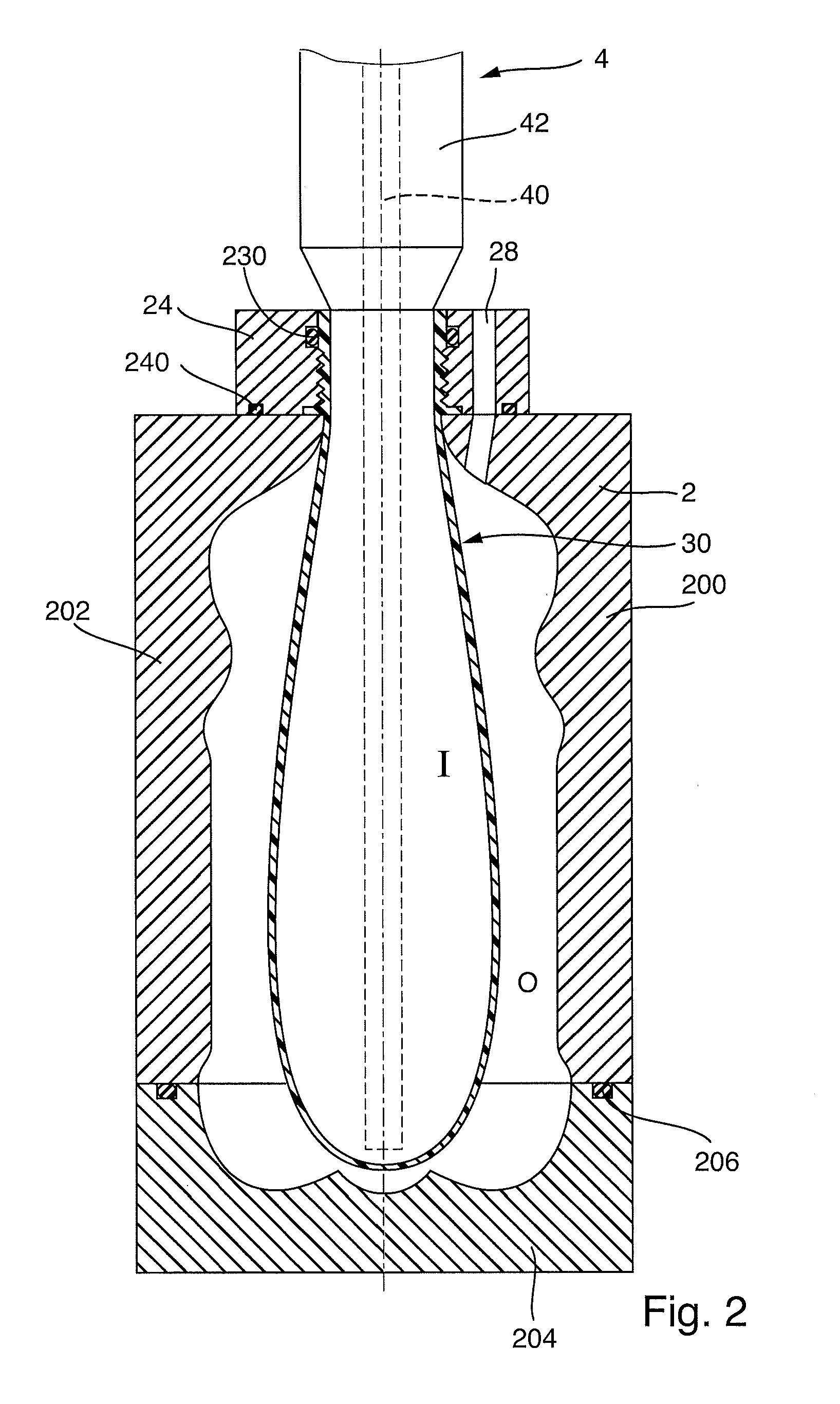

[0078]In FIGS. 1 to 4, a device 1 for manufacturing plastic containers and for filling them with a fill product is shown schematically. For manufacturing the plastic containers, a blow mold 2 is provided, which has a cavity 20 with an inner wall 22 that corresponds to the outer contours of the plastic container that is to be manufactured. In the blow mold 2, a plastic container can be manufactured in a manner known in the art from a heated preform by means of blow molding or stretch blow molding. In the stretch blow molding process, the heated preform is pre-stretched with a stretching rod and simultaneously pre-inflated, then fully blow molded by means of p

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap