Combination Including a Ratchet Wrench and a Driving Member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

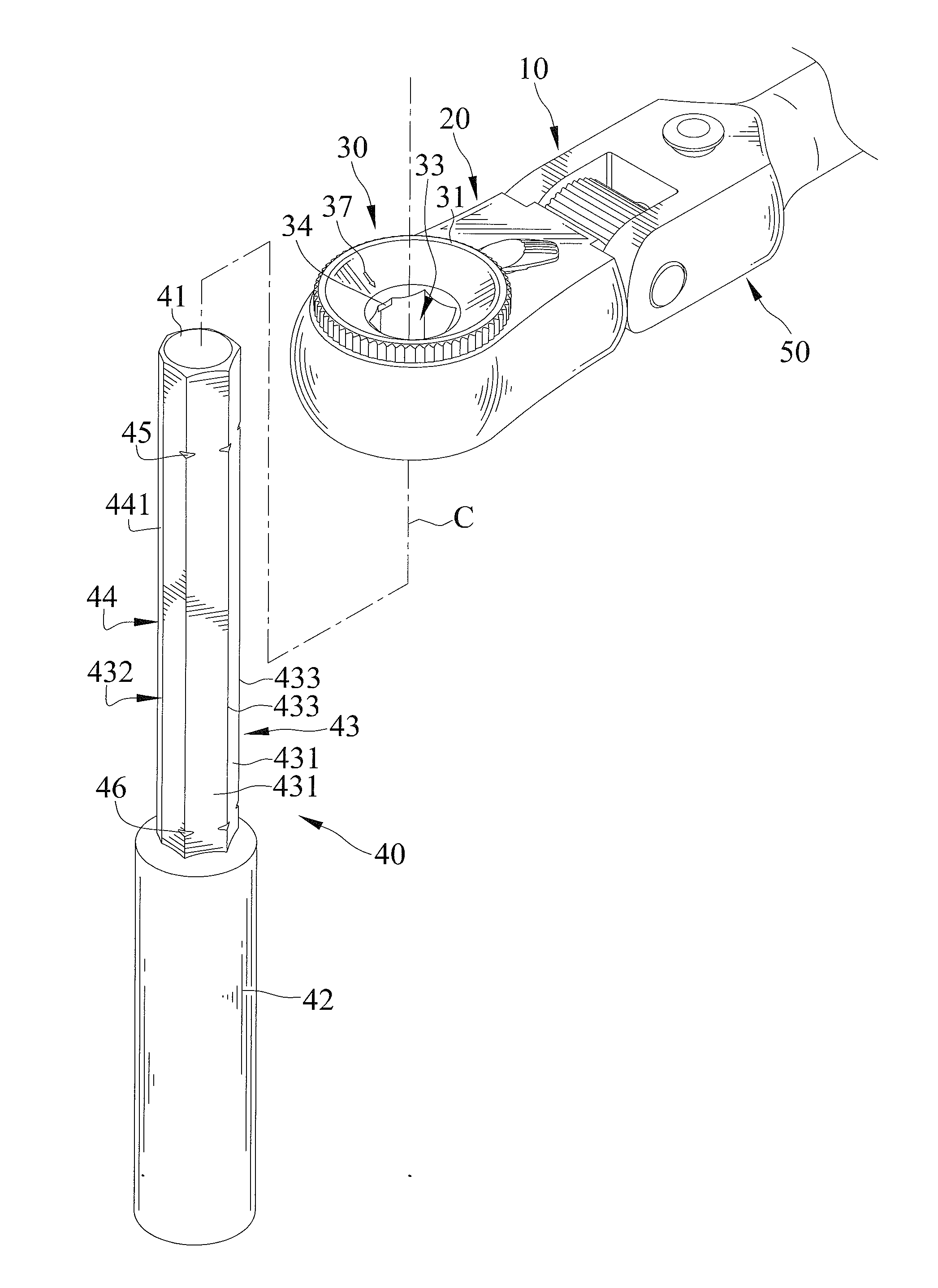

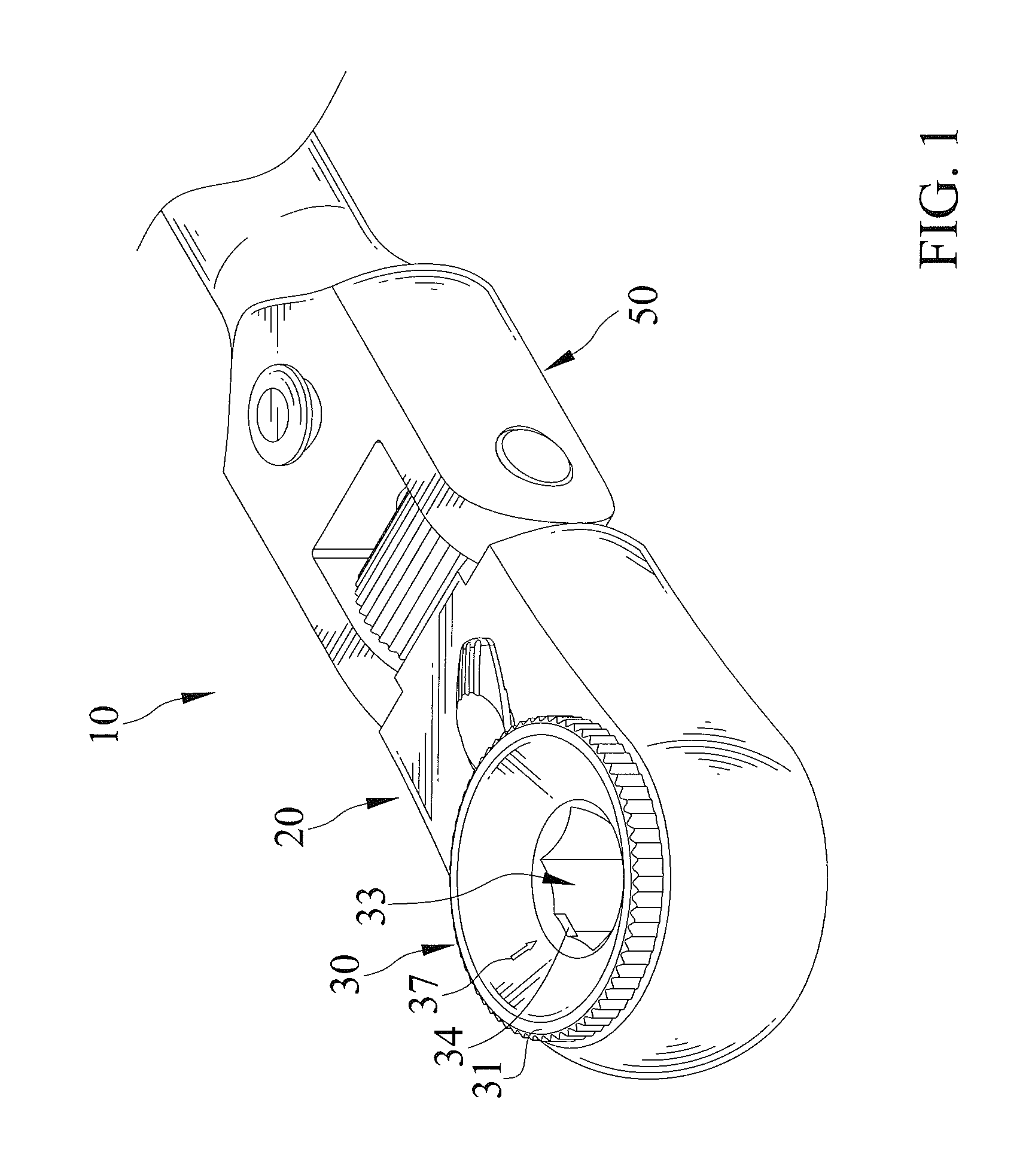

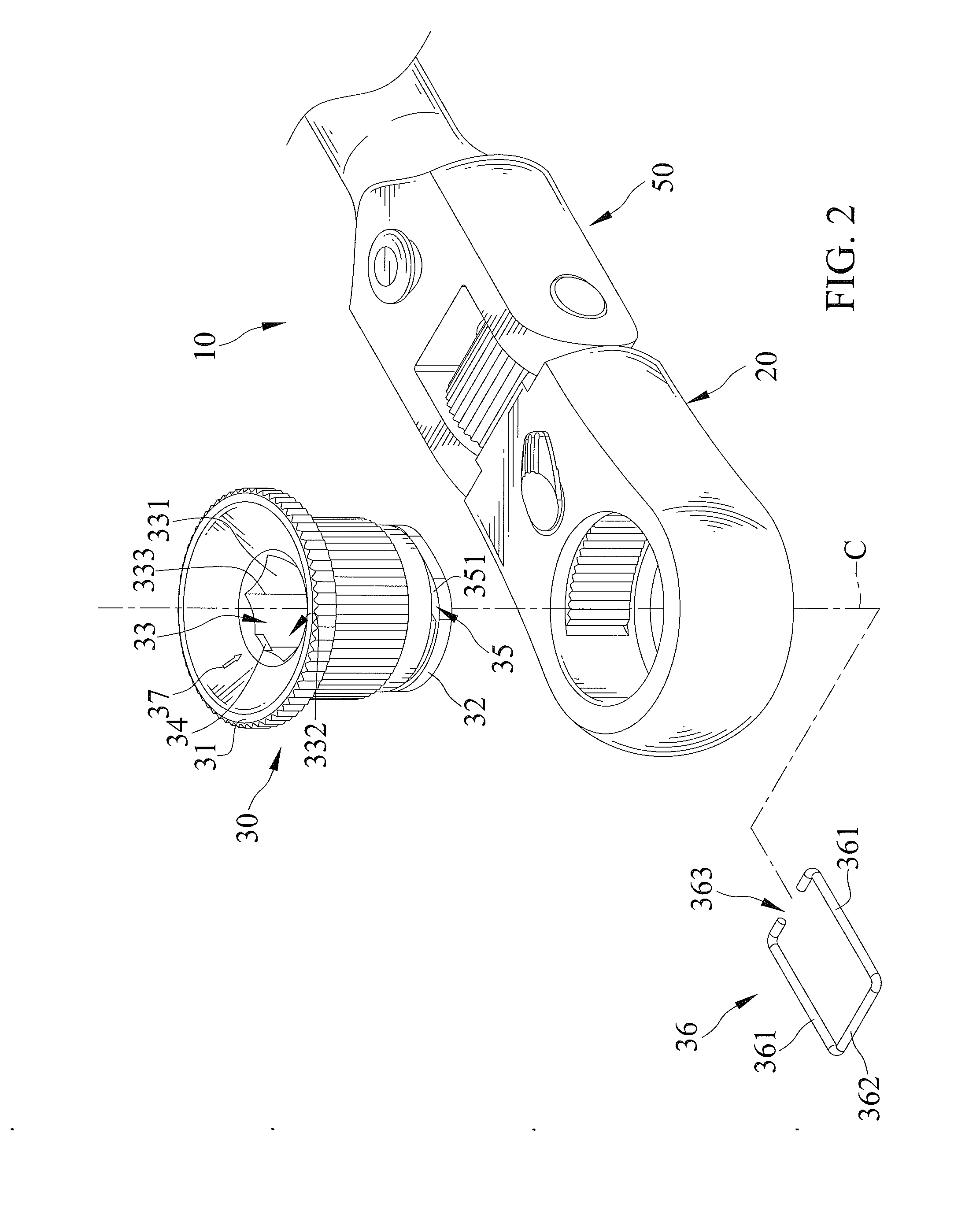

[0047]FIGS. 1-11 show a combination including a ratchet wrench 10 and a driving member 40 of a first embodiment according to the present invention. Ratchet wrench 10 includes a body 20, a ratchet wheel 30, and an operative portion 50.

[0048]Body 20 is pivotably connected to operative portion 50 and can be retained in a selected angular position relative to operative portion 50. Operative portion 50 is adapted to be gripped by a user.

[0049]Ratchet wheel 30 is mounted in body 20 and is rotatable about a rotational axis C relative to body 20. Ratchet wheel 30 includes a first side 31 and a second side 32 spaced from first side 31 along rotational axis C. Ratchet wheel 30 further includes a driving hole 33 extending from first side 31 through second side 32. Driving hole 33 is polygonal. In this embodiment, driving hole 33 includes an inner periphery 332 having a plurality of abutment surfaces 331 contiguous to each other and arranged along a circumferential direction about rotational axis

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap