Movable wrench double-face polishing clamp

A technology of adjustable wrench and surface polishing, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems of wasting manpower, excessive processing of adjustable wrenches, and inaccurate positioning, so as to improve work efficiency and save human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

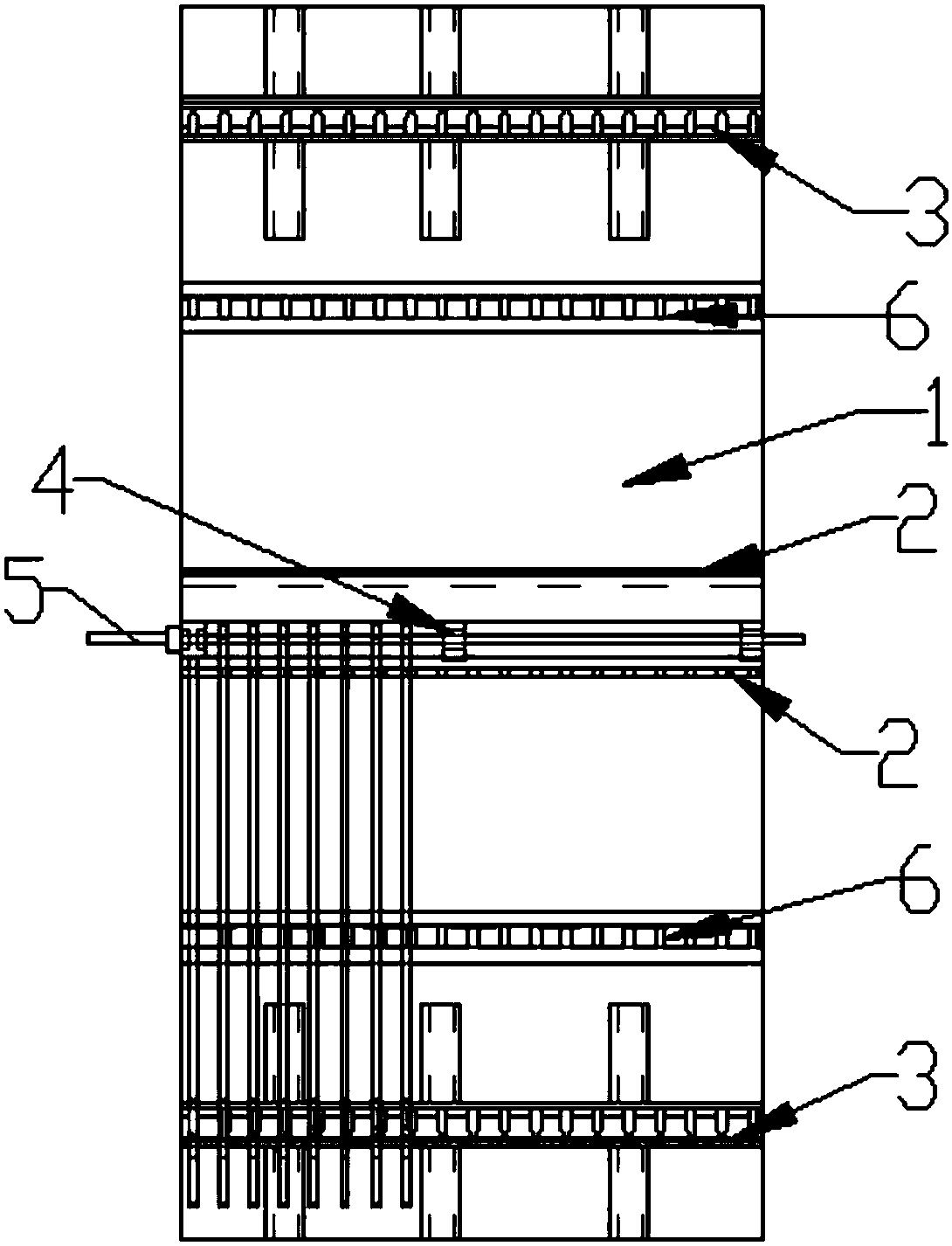

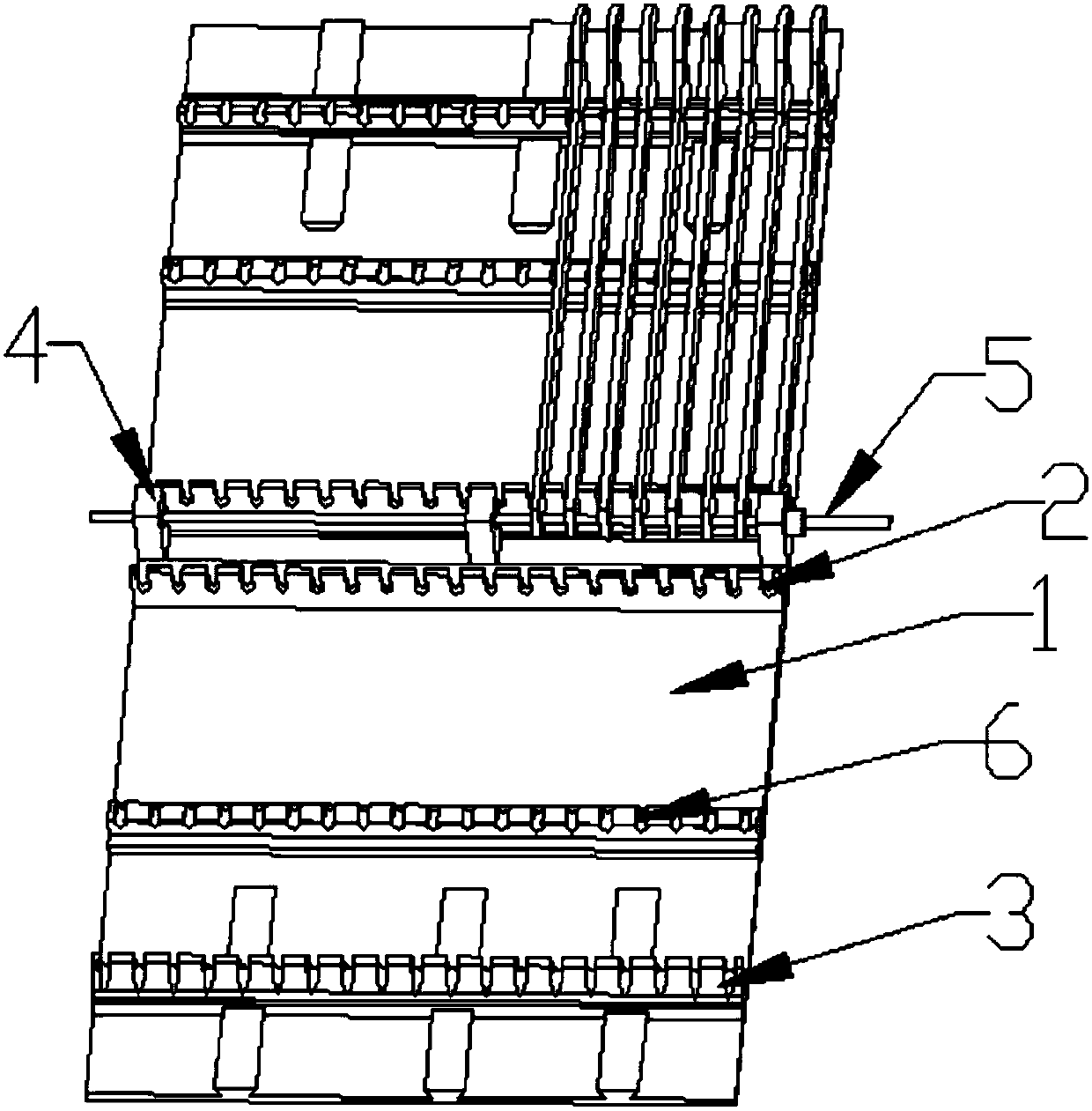

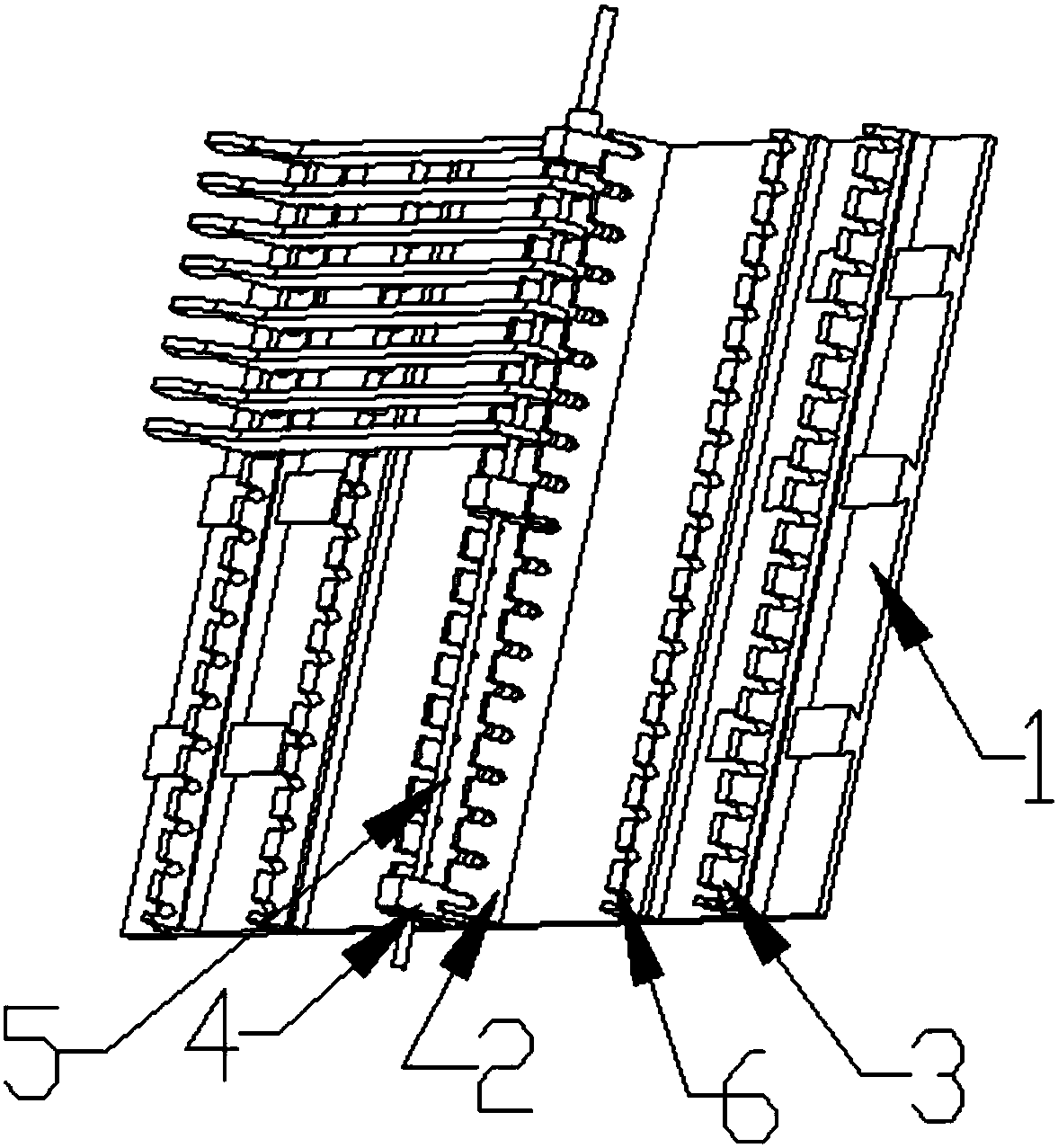

[0017] Such as Figure 1-Figure 3 As shown, the specific structure of the present invention is: a double-surface polishing fixture for an adjustable wrench, including a bottom plate 1 and a turning device 4 arranged in the middle of the bottom plate, the turning device 4 has a turning through hole, and the turning through hole diameter is equal to or Slightly larger than the aperture of the through hole at the end of the handle of the adjustable wrench; it also includes a rotating rod 5 whose diameter is slightly smaller than the diameter of the through hole at the end of the handle of the adjustable wren

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap