Nut and washer assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

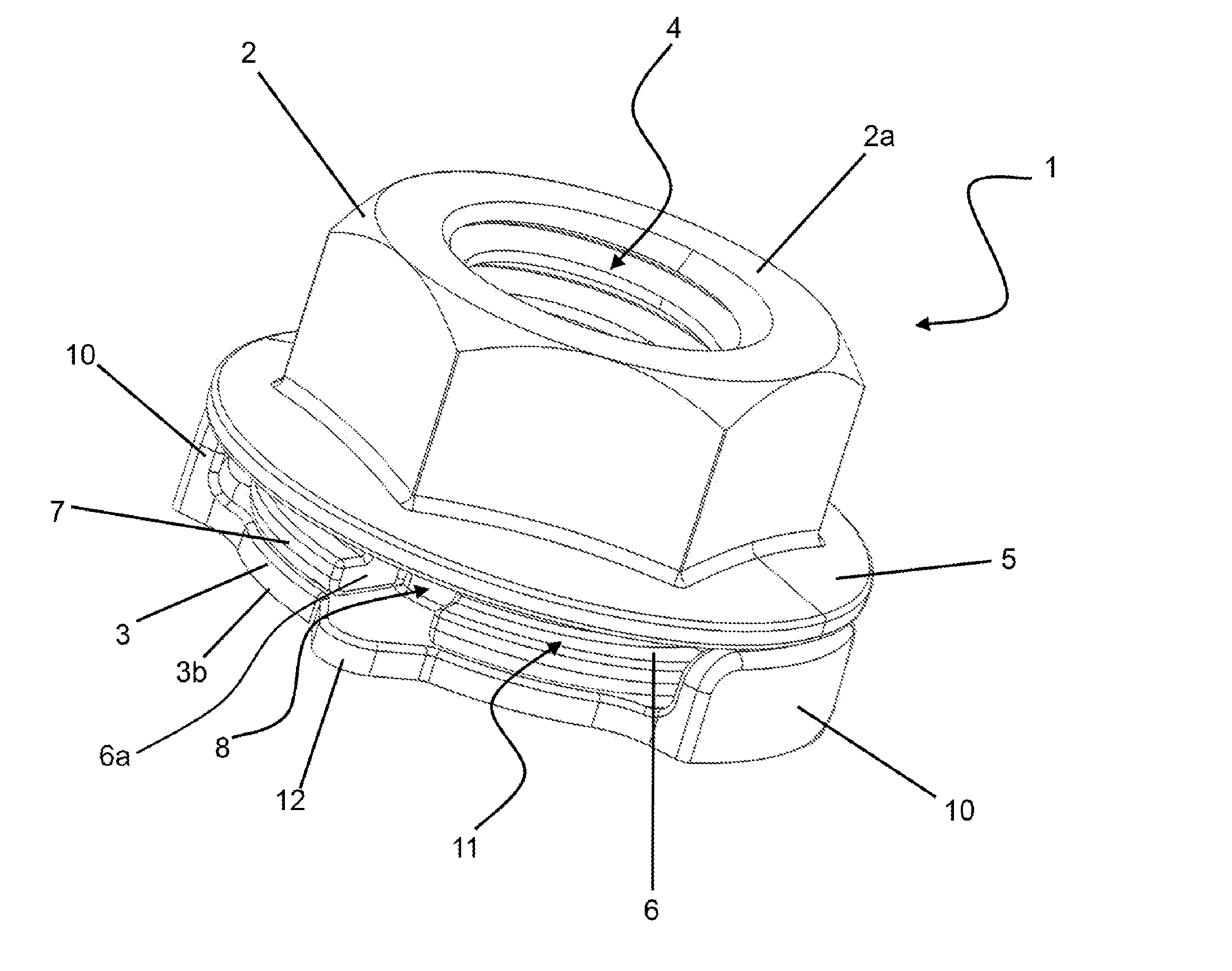

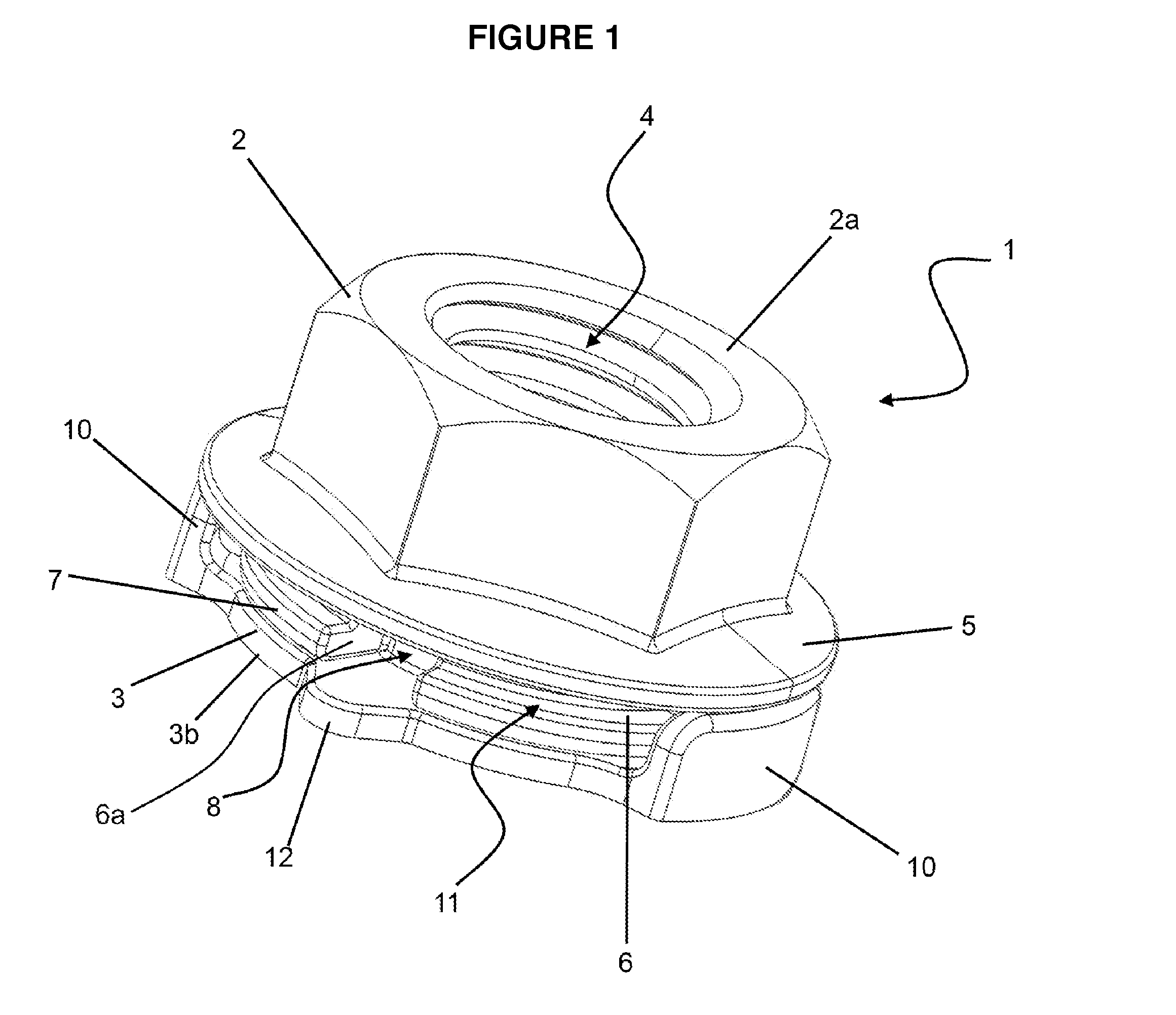

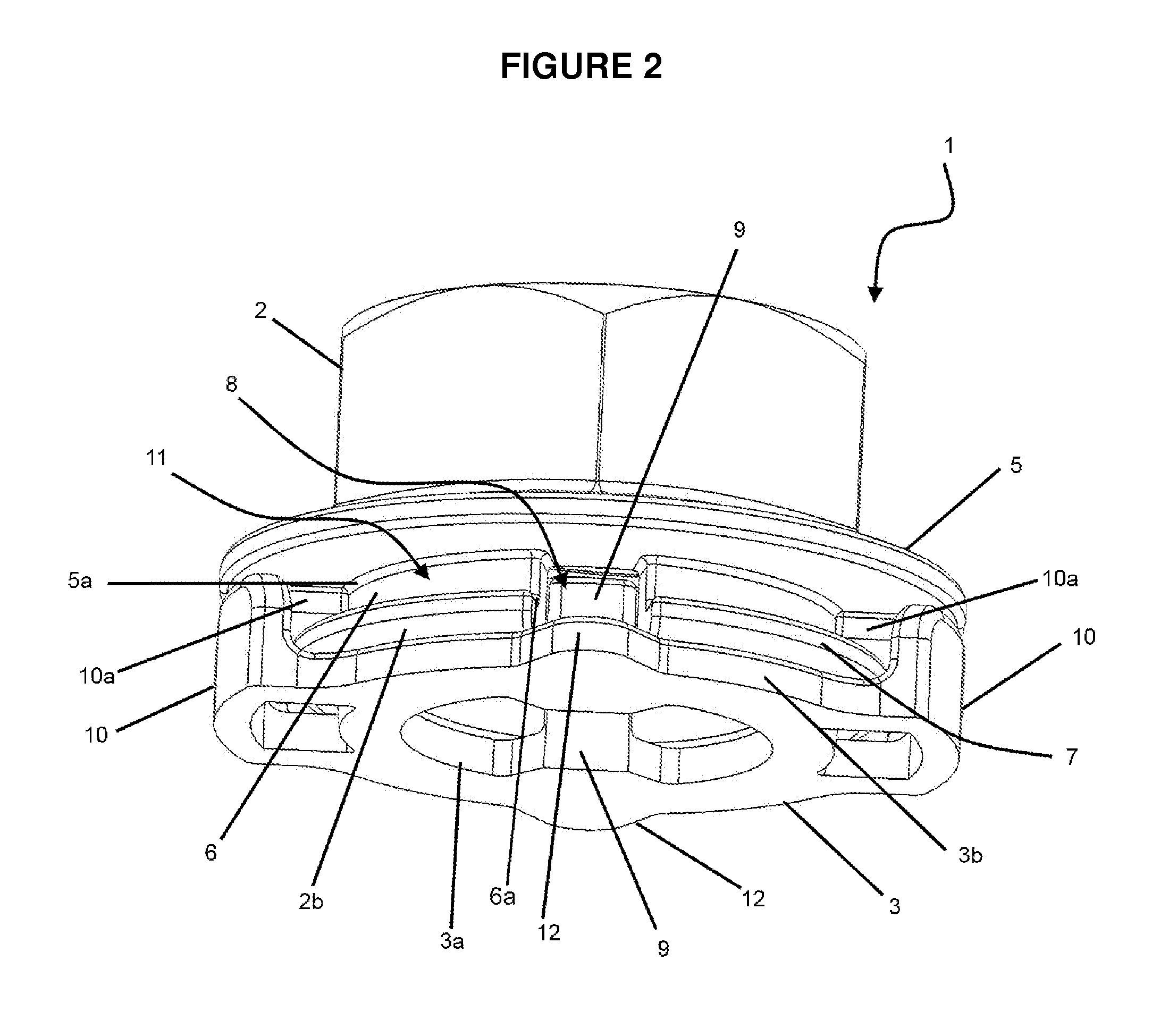

[0071]The present invention is illustrated in FIGS. 1 and 2 and includes an assembly (generally indicated by arrow 1) of a nut (2) and washer (3) which are specially configured to cooperate with each other.

[0072]The body of the nut (2), in the illustrated embodiment, is six-sided, mimicking a conventional nut which is commonly used in the engineering and construction industries. A threaded central passage (4) for a fastener (not shown) runs between the top (2a) and the base (2b) of the nut.

[0073]Extending laterally outwards from its lower edge, the nut (2) includes a first flange (5), which acts as a shield for the washer. The flange helps to protect the washer from the fastening tool (not shown) used to manipulate the nut.

[0074]Depending from the interior edge (5a) of the first flange, is a neck (6), the lower edge (6a) of which is provided with a second flange (7) extending laterally outwards in more or less the same plane as the first flange (5).

[0075]It will be noted that the nut (

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap