Outboard motor mounting structure and outboard motor vessel provided therewith

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

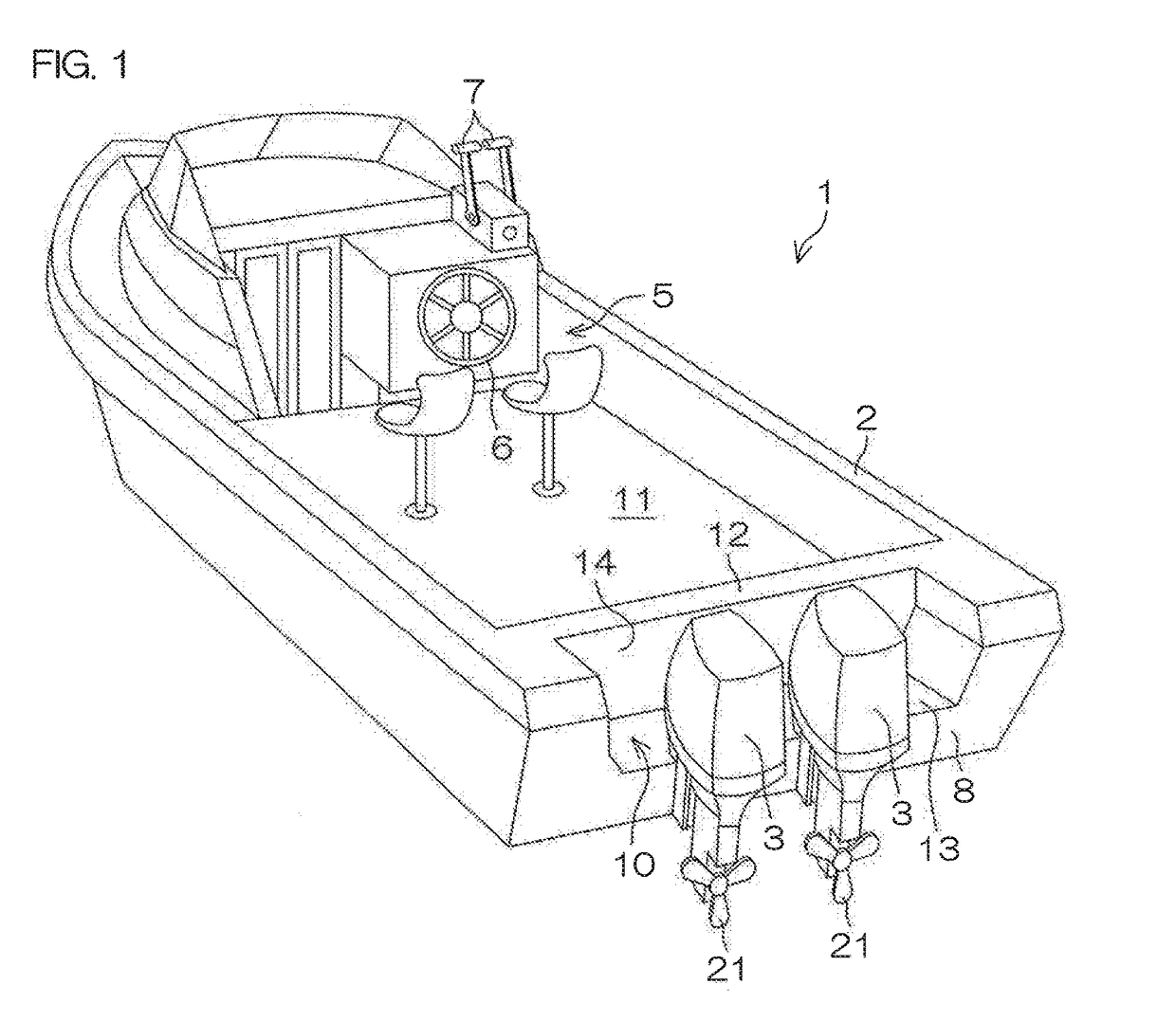

[0050]FIG. 1 is a perspective view of an outboard motor vessel according to a preferred embodiment of the present invention. The outboard motor vessel 1 includes a hull 2 and an outboard motor 3 mounted on the hull 2. In the present preferred embodiment, two outboard motors 3 preferably are arranged on the right and left sides, respectively, and are attached to the stern of the hull 2.

[0051]The hull 2 includes a navigator seat 5 near an intermediate position with respect to a front-rear direction. Operating devices, such as a steering wheel 6 and a shift / throttle lever 7, are disposed at the navigator seat 5. Outboard motors 3 (in the present preferred embodiment, a pair of outboard motors 3) are attached to a stern plate 8 of the hull 2. A motor well 10 is provided in the hull 2 in front of the outboard motors 3. A partition wall 12 that partitions a residence space 11 for the crew is disposed in front of the motor well 10. The motor well 10 is a concave portion having a necessary a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap