External Gear Pump Integrated with Two Independently Driven Prime Movers

a prime movers and external gear technology, applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of affecting sheared materials are known to be detrimental to the functionality of the system, and the system can be particularly troublesome. to achieve the effect of reducing or eliminating the problem of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

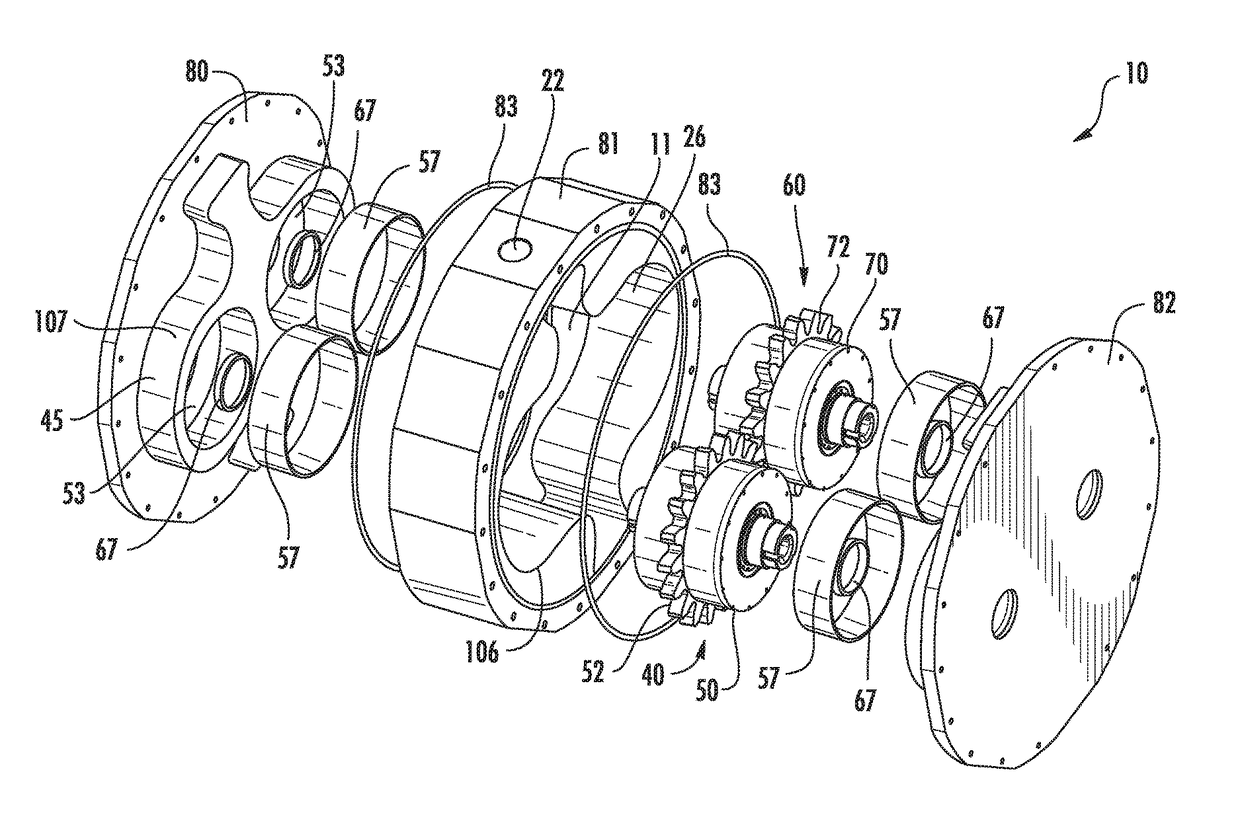

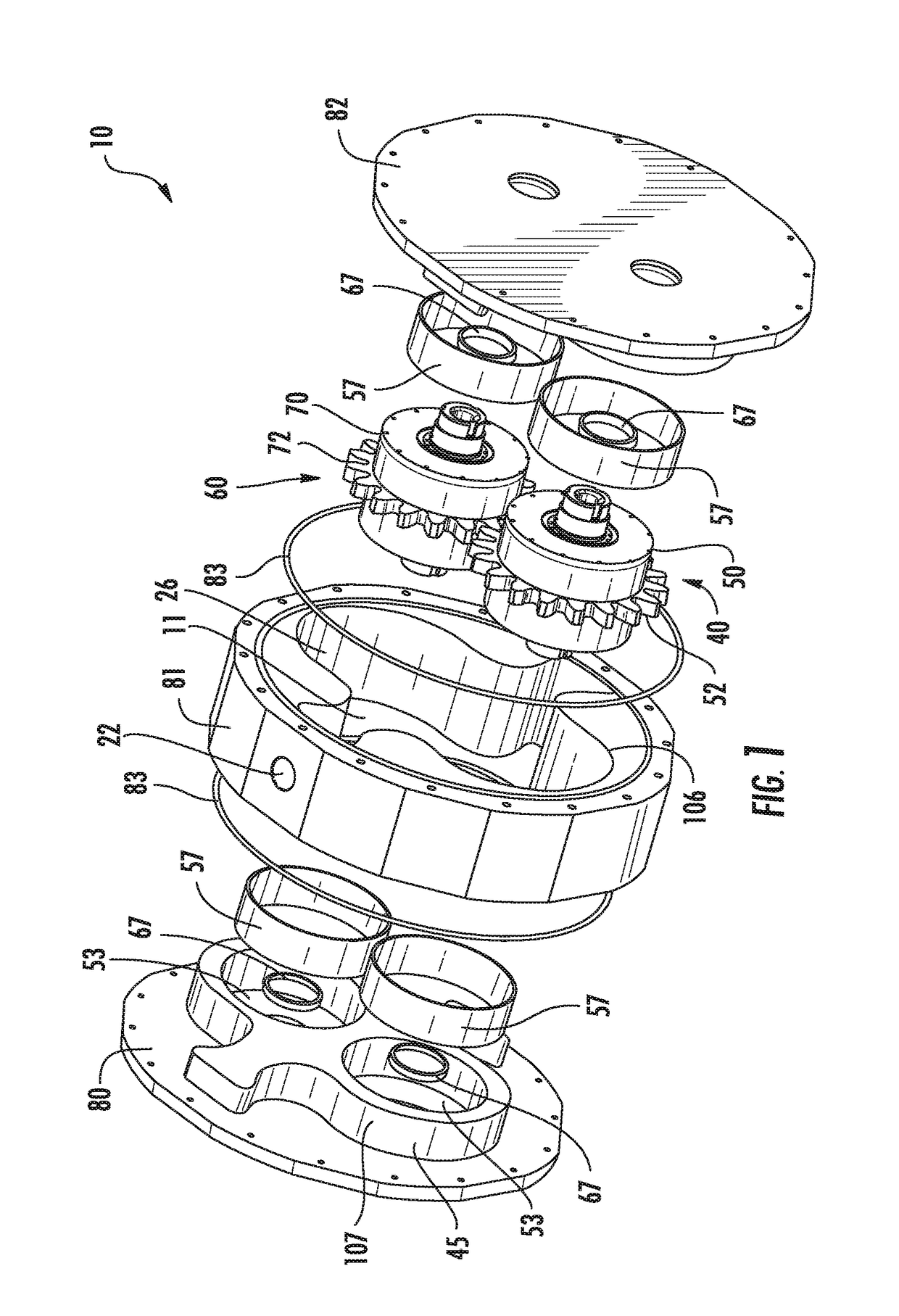

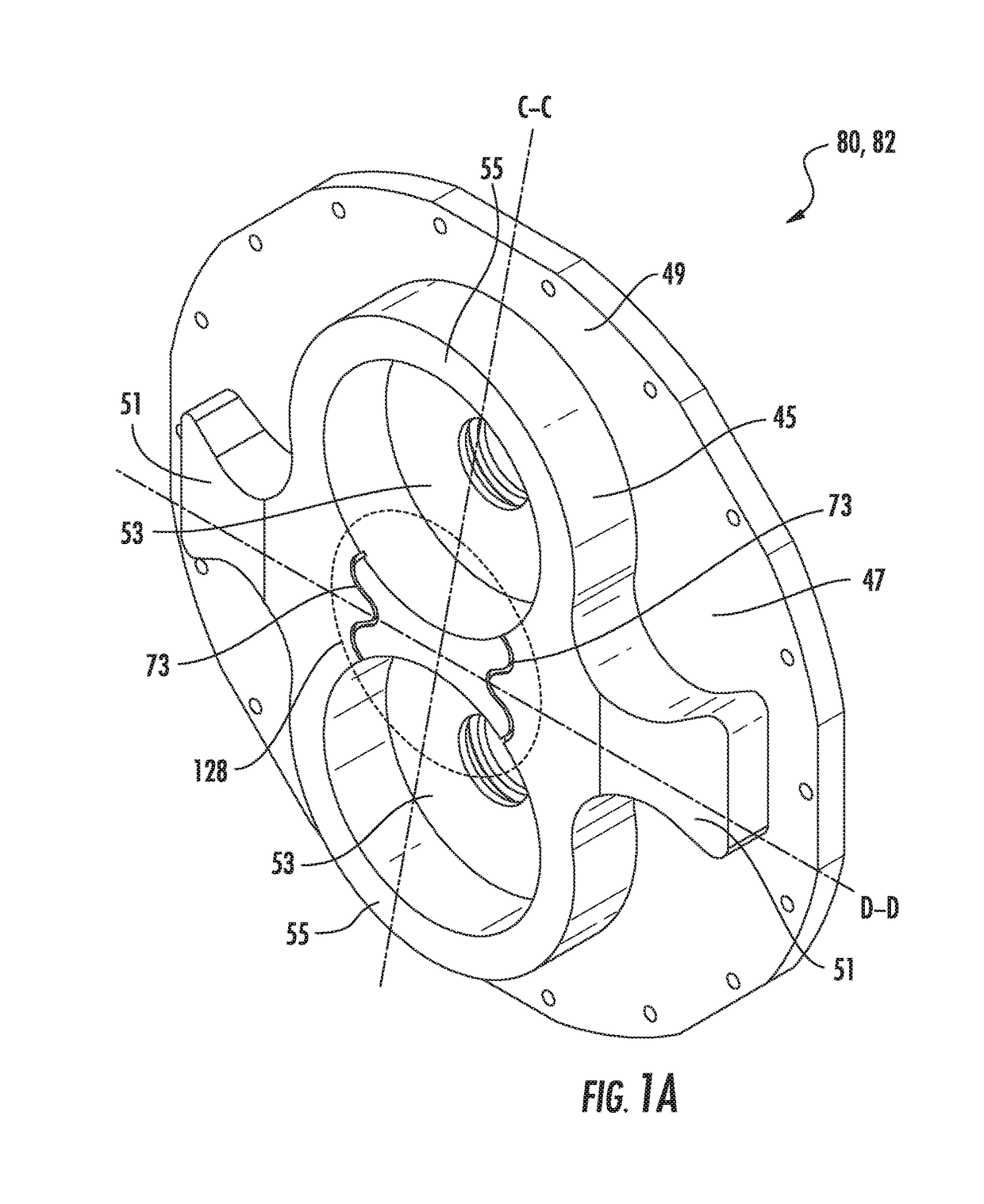

[0036]Exemplary embodiments of the present invention are directed to a pump with independently driven fluid drivers disposed between two self-aligning balancing plates that form part of the pump casing. These exemplary embodiments will be described using embodiments in which the pump is an external gear pump with two prime movers, the prime movers are electric motors and the fluid displacement members are external spur gears with gear teeth. However, those skilled in the art will readily recognize that the concepts, functions, and features described below with respect to electric-motor-driven external gear pump with two fluid drivers can be readily adapted to external gear pumps with other gear designs (helical gears, herringbone gears, or other gear teeth designs that can be adapted to drive fluid), to prime movers other than electric motors, e.g., hydraulic motors or other fluid-driven motors, or other similar devices that can drive a fluid displacement member, and to fluid displacem

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap